Stepping feeding mechanism

A hopper and discharge port technology, applied in the field of stepping feeding mechanism, can solve the problems of slow production speed, affecting the heat sealing of upper and lower water-soluble films, and low working efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

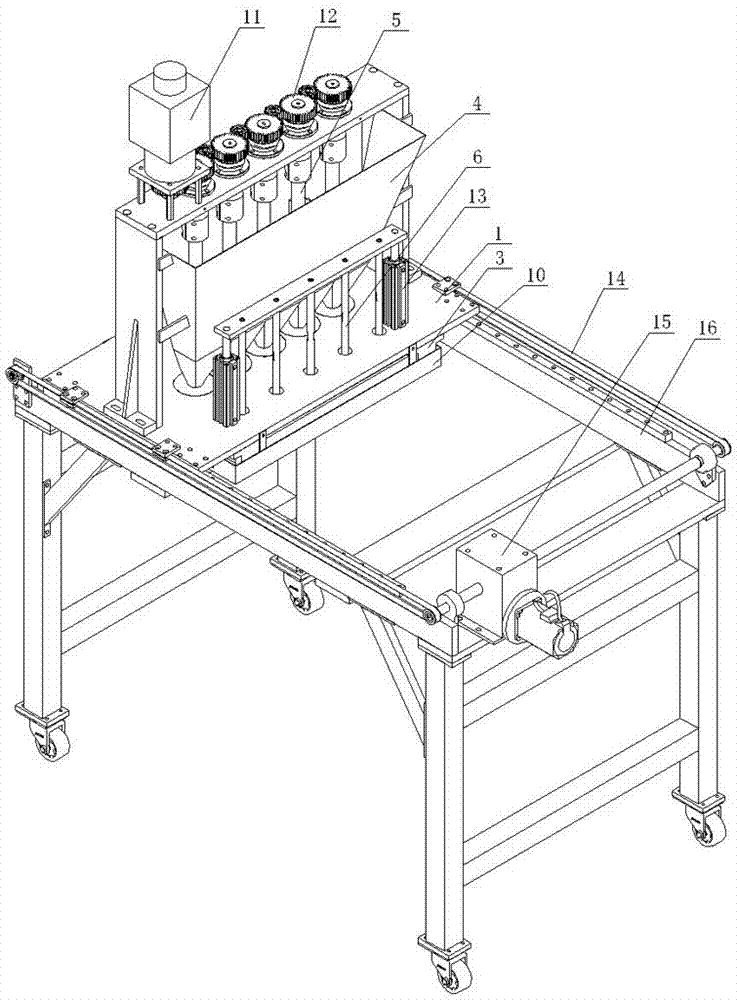

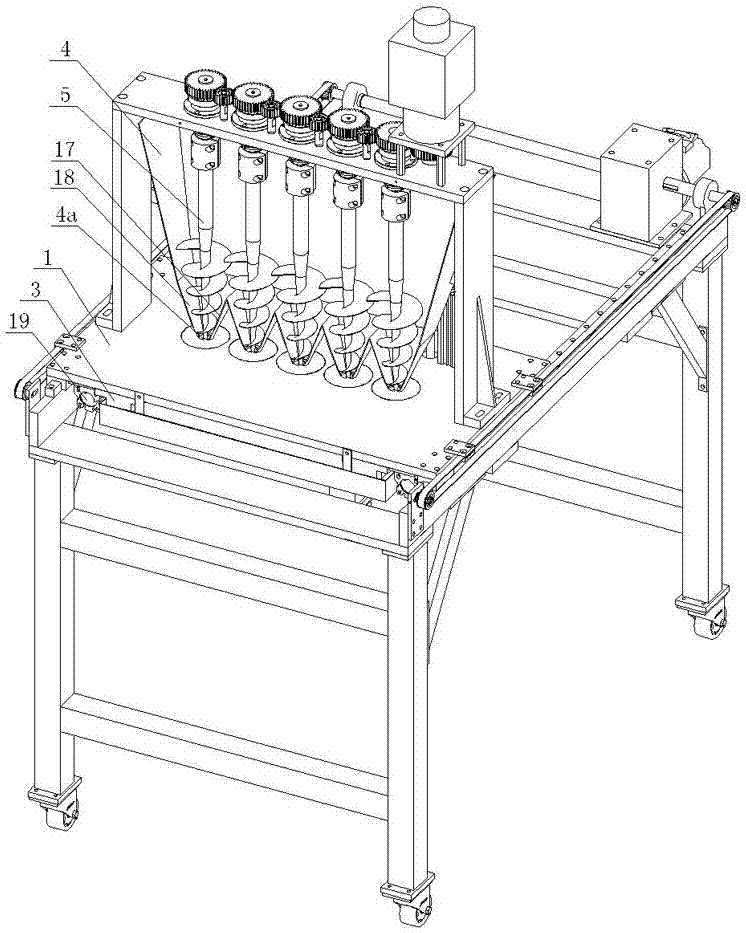

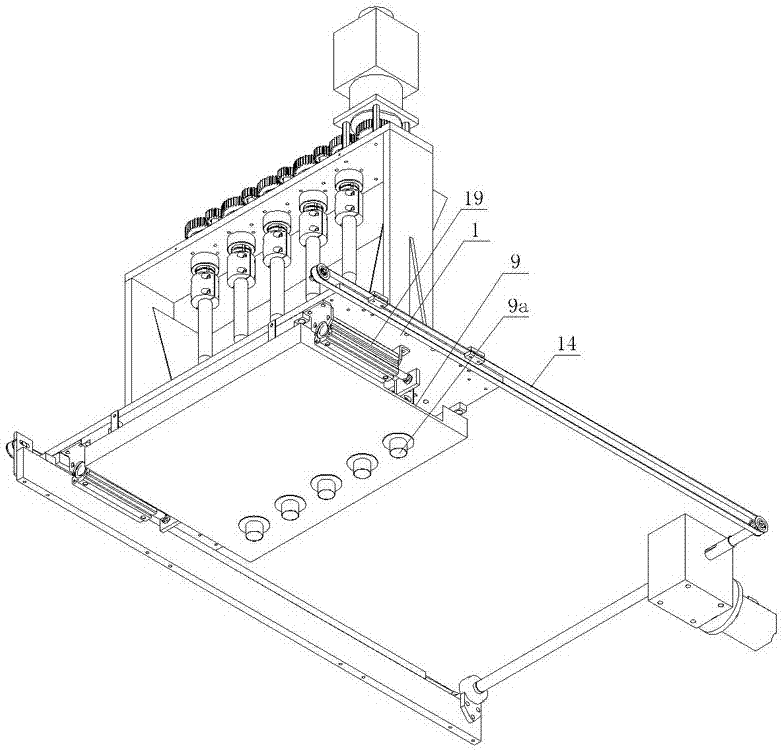

[0016] As shown in the figure, the step-by-step feeding mechanism of the present invention includes a hopper part, and the hopper part is installed on the upper plate 1, and the upper plate 1 slides back and forth on the frame 16 and is driven by the main motor 15 to carry out stepping transmission, and the upper plate 1 It is connected with the synchronous belt 14, and the pulley of the synchronous belt 14 is connected with the deceleration output of the main motor 15. The upper plate 1 is provided with a feed hole 1a and a feed hole 1b in the front and rear direction, the feed hole 1a is opposite to the hopper outlet 4a of the hopper part, and a feed head 6 is arranged above the feed hole 1b, and a feed head 6 The up and down activities are set to be driven by the material cylinder 13. The material cylinder 13 is fixedly installed on the upper plate 1, and the upper plate 1 is fixedly connected with the lower plate 3. There is a pushing plate 2 in the middle of the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com