Step compression feeding mechanism

A material trough and material technology, applied in the field of step compression feeding mechanism, can solve the problems of slow production speed and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

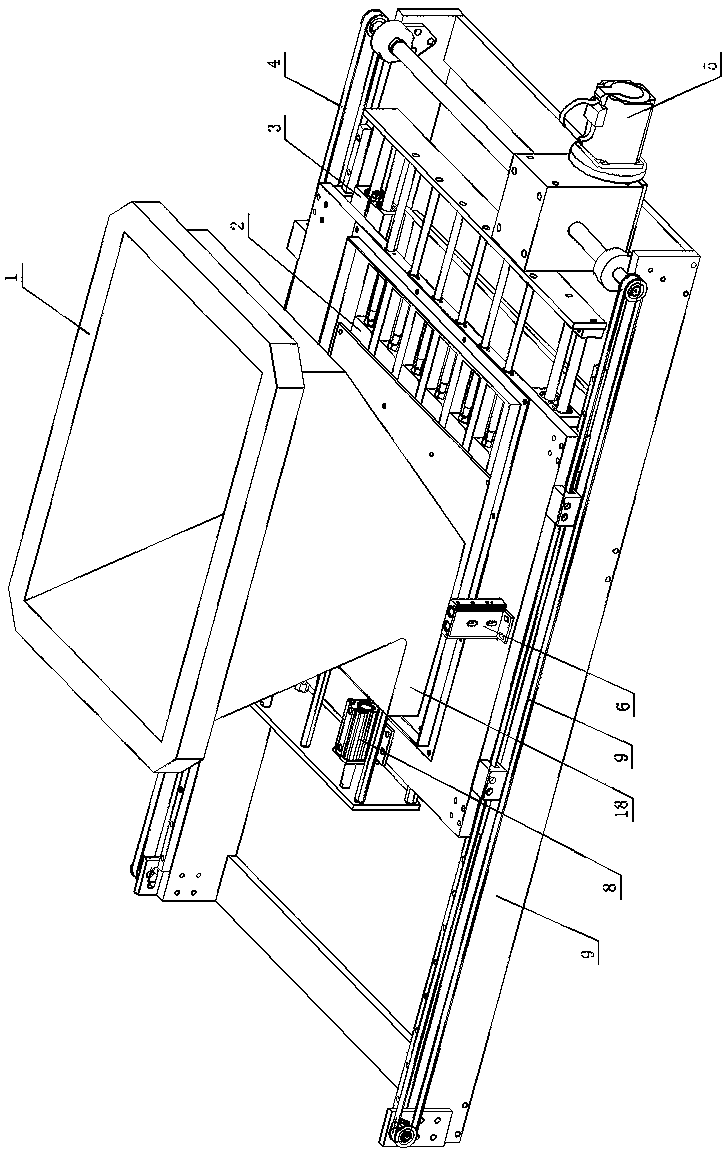

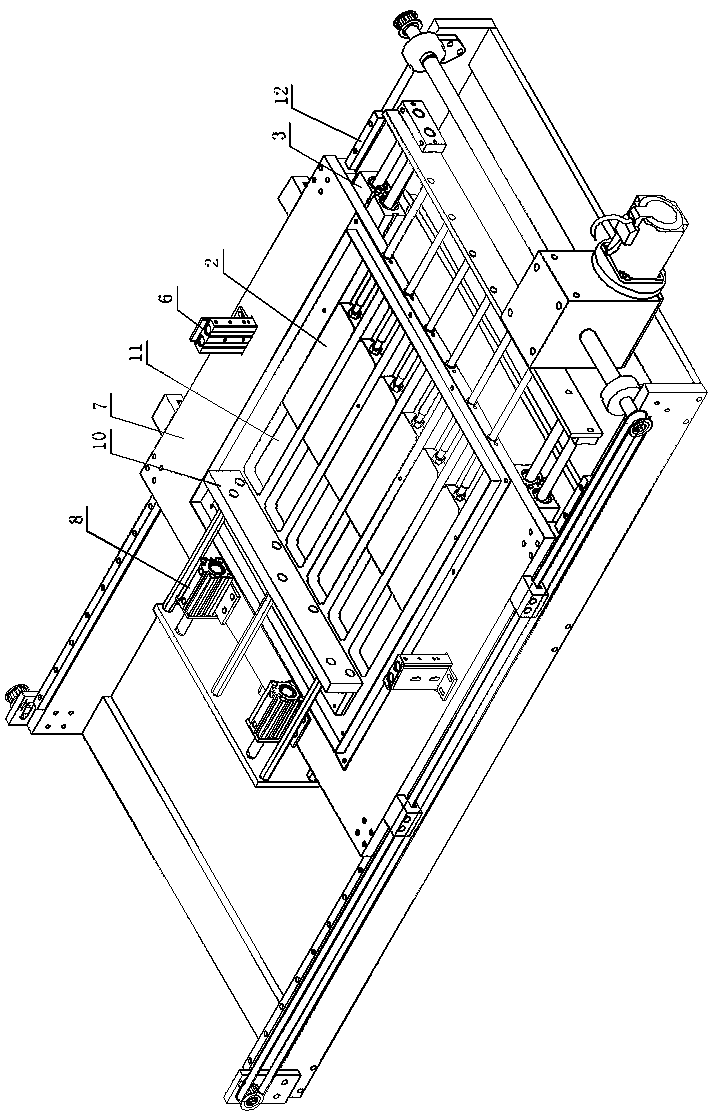

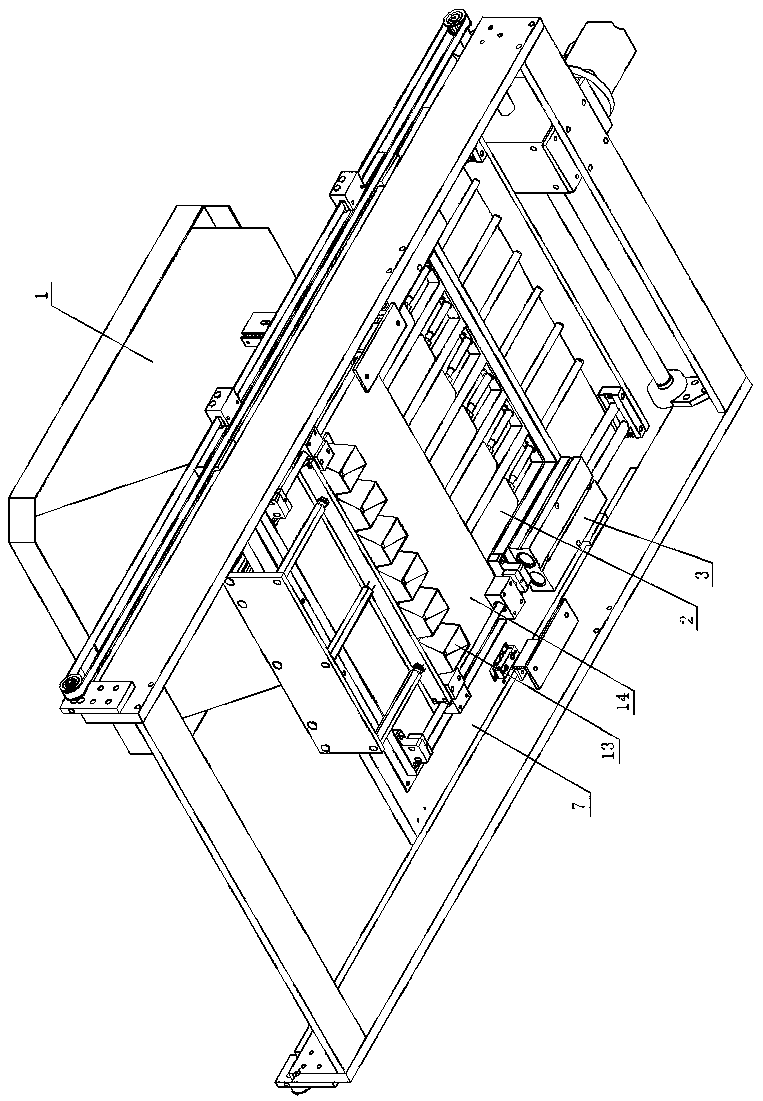

[0017] As shown in the figure, the step-by-step compression feeding mechanism of the present invention includes a storage hopper 1, and the storage hopper 1 is installed on the main board 7. The main board 7 is provided with six parallel feed troughs, and the push block 2 is arranged in the feed trough. 2. It is movable in the trough, and the movement of the push block 2 is promoted by the first cylinder 3. A material extrusion space 11 is enclosed between the chute and the pushing end surface of the push block 2. The material extrusion space 11 and the storage hopper 1 Align with the outlet of the material chute, a material partition 14 is attached to the bottom surface of the chute, and a scraper 10 is attached to the top surface of the chute, and the movement of the material partition 14 and the scraper 10 is controlled by the second The cylinder 8 is propelled, and the first and second cylinders are fixedly installed on the main board 7; the material partition 14 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com