Manufacturing and application method of piezoelectric intelligent gasket embedded with inclined fibers

A gasket and fiber technology, which is applied to the measurement of the properties of piezoelectric devices, electromagnetic measurement devices, and testing of mechanical parts, etc., to avoid signal uncertainty, save layout space, and be easy to replace.

Pending Publication Date: 2022-06-10

HUNAN UNIV OF SCI & TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006]The main purpose of the present invention is to provide a method of manufacturing and applying a piezoelectric smart gasket embedded with inclined fibers, aiming to utilize the piezoelectric sensor embedded with inclined fibers Integrate with the gasket structure of the bolts to overcome the problems that the sensors pasted on the surface of the structure are easily affected by external environmental factors and reduce performance, and the sensors embedded in the structure are difficult to replace and the embedding process is complicated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

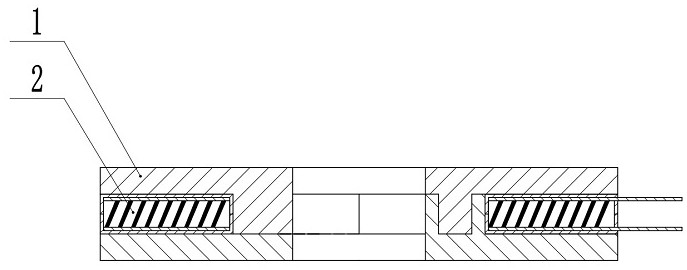

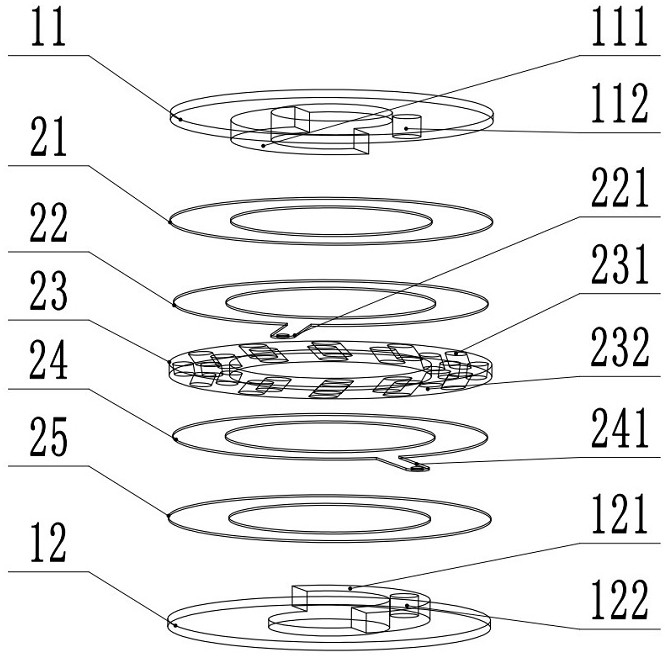

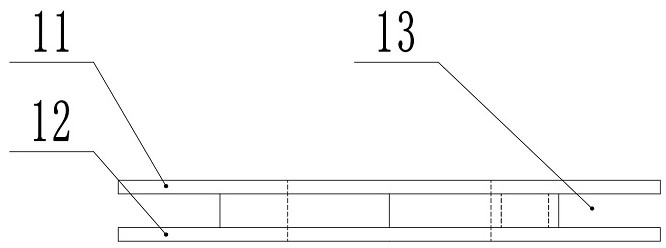

The invention discloses a manufacturing and application method of a piezoelectric intelligent gasket embedded with inclined fibers, the piezoelectric intelligent gasket comprises a shell and a piezoelectric sensor embedded with the inclined fibers, the shell is composed of a circumferential annular groove formed by concentric cooperation of a male gasket and a female gasket, and the piezoelectric sensor embedded with the inclined fibers is embedded with the annular groove formed by concentric cooperation of the male gasket and the female gasket. The piezoelectric fiber composite material is composed of a piezoelectric fiber composite material, an electrode layer and an insulation shielding layer. The piezoelectric fiber composite material comprises inclined piezoelectric fibers and an epoxy resin matrix, according to the piezoelectric intelligent gasket, the embedded inclined fiber piezoelectric sensor and the gasket structure of the bolt are integrated, the sensor senses the stress-strain change and other information of the connected workpiece structure, the structural damage is monitored in real time, meanwhile, the change of the bolt pre-tightening force can be monitored, the arrangement space of the sensor is saved, the sensor is easy to replace, and the cost is reduced. Compared with a common piezoelectric element, the piezoelectric sensor embedded with the inclined fibers has flexibility and can bear certain impact, and the failure rate is reduced.

Description

technical field [0001] The invention relates to a manufacturing and application method of a piezoelectric intelligent gasket embedded with inclined fibers. Background technique [0002] As a new application field with innovation, structural damage monitoring is the key to equipment production quality management and operation safety monitoring. It has important engineering significance and application value to ensure the integrity of equipment structure and work safety. Through the sensor network, the information related to the health state of the structure is sensed online, and the data is transmitted, collected and processed by means of data collection and signal analysis, and the characteristic value of the sensed signal is obtained, compared with the healthy signal, and the current state of the structure is analyzed. Diagnose and identify, realize the prediction of the failure mode and service life of the structure, evaluate the damage status of the structure, and use the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M13/00G01L5/24G01L1/16G01B7/16

CPCG01M13/00G01L5/24G01L1/16G01B7/16

Inventor 蒋帅沈意平刘缘王送来翁晶支余林刘翊傅志强

Owner HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com