Assembly type embossing device

An assembled and embossed technology, applied in the direction of machining/deformation, to achieve the effect of convenient replacement and convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

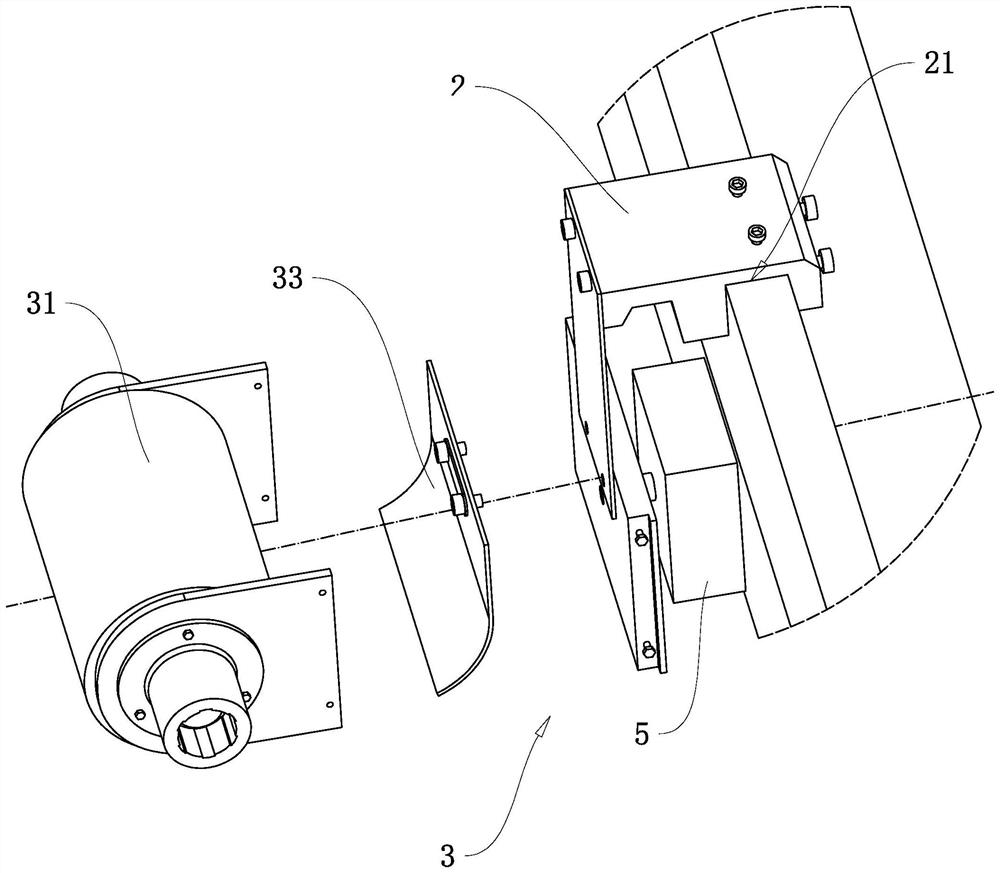

[0040] When it is necessary to switch between four-sided embossing and double-sided embossing, it is more convenient to replace the patterned pressing roller 31 on one side with a non-embossed pressing roller 31 for double-sided embossing.

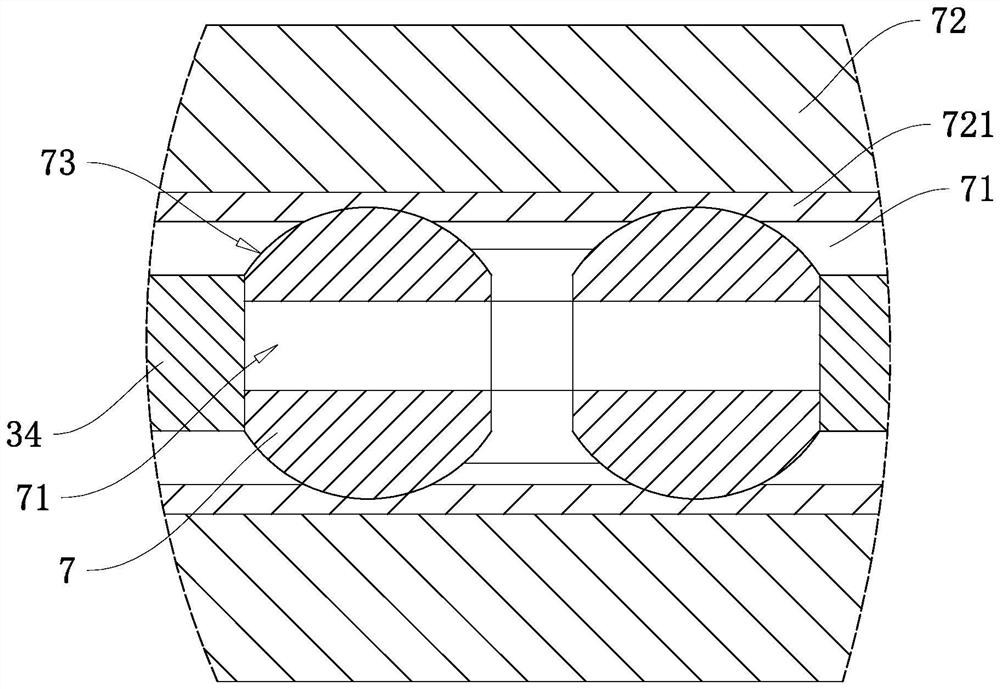

[0041] refer to Figure 5 , in other embodiments, a coaxial integral connection is provided between the rotating shafts 34 of the pressing roller group 6 to facilitate the overall disassembly of the pressing roller group 6 and the mounting frame, further improving the switching between four-sided embossing and two-sided embossing Ease of use.

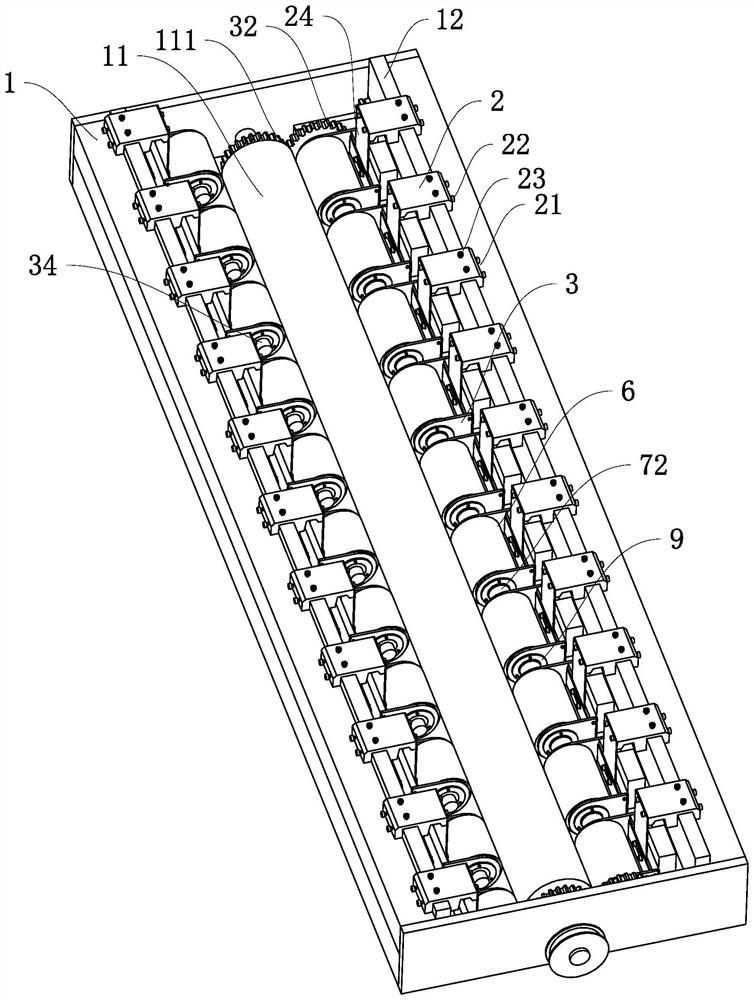

[0042] refer to figure 1 and figure 2 , a drive mechanism is provided on the support 3, the drive mechanism includes a drive cylinder 5, one end face of the piston rod of the drive cylinder 5 is fixedly connected with the elastic plate 24 and the support 3 by bolts, and the drive cylinder 5 is pressed against the machine by the cylinder body when the drive cylinder 5 is started. The frame 1 reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com