Drying and sorting device for toad-eating pills

A sorting device and toad-eating technology are applied in drying, solid separation, and drying of solid materials to achieve the effects of shortening time, improving efficiency, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

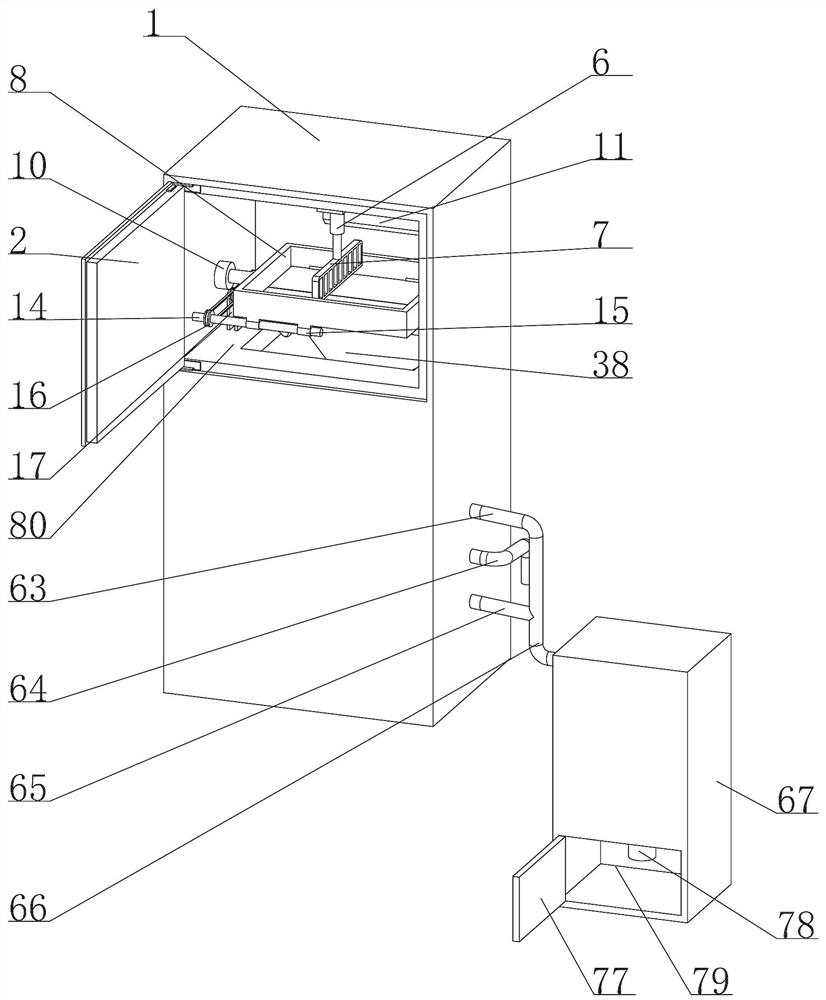

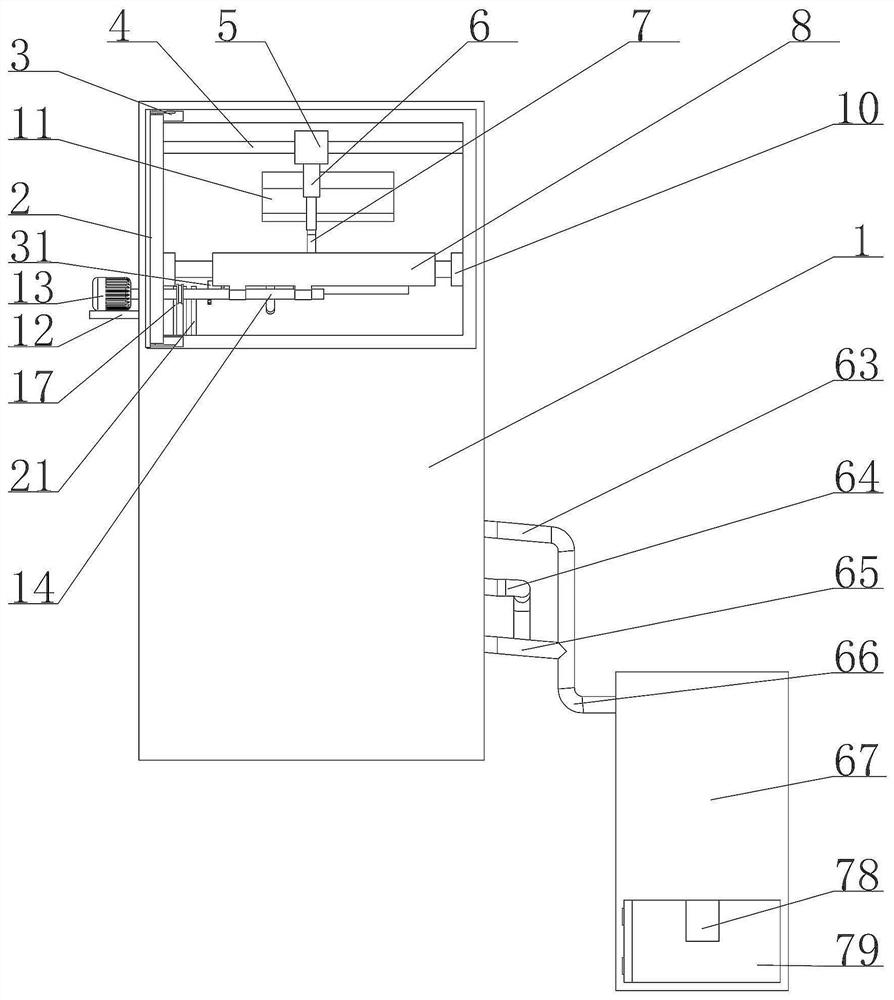

Embodiment 1

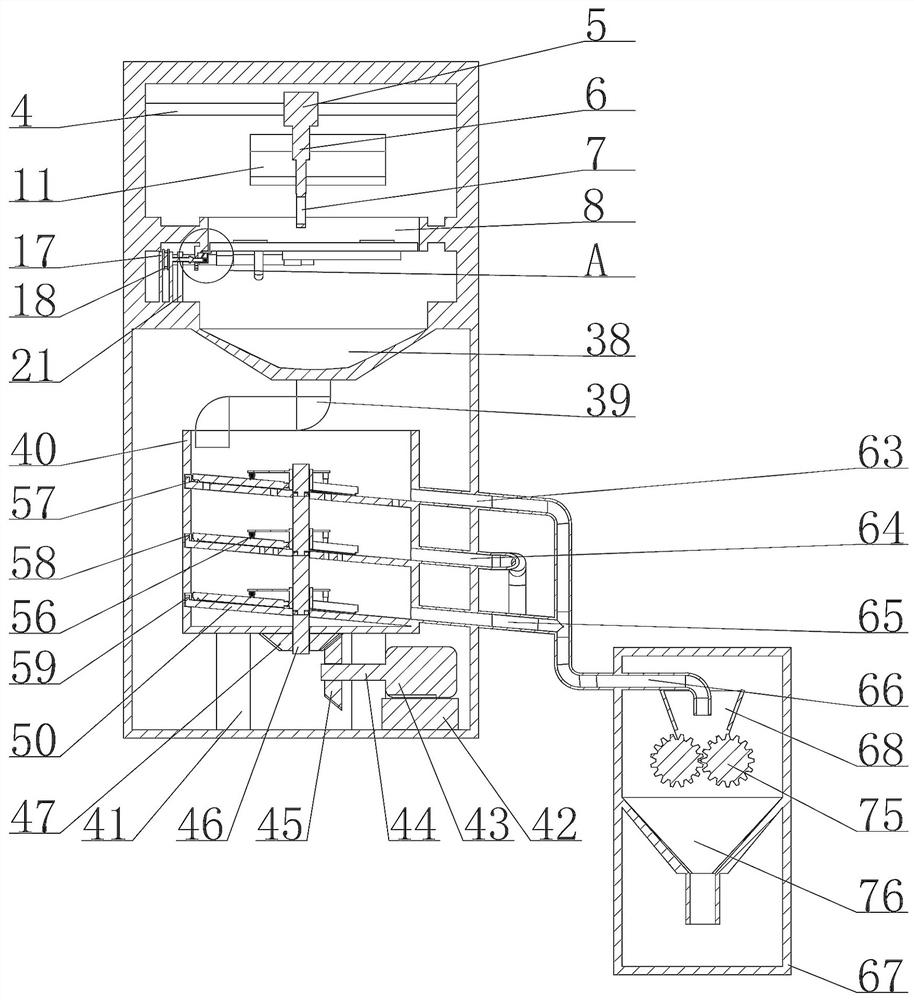

[0029] Embodiment 3, on the basis of Embodiment 2, in order to prevent the loading plate 26 from being opened due to the rotation of the driving lever 28 due to the pressure of the pills, the present invention provides a position-limiting fixation of the loading plate 26 to ensure that the loading plate 26 is The object plate 26 will not be opened due to bearing pressure during the drying process. Specifically, the middle part of the transmission chain 25 is located between the driving wheel 16 and the second driven wheel 19 and is movably connected with the first driven wheel 18. The first driven wheel 18 A driven wheel 18 will rotate as the driving wheel 16 rotates to drive the movement of the transmission chain 25. The outer side of the first driven wheel 18 is fixedly connected with a first fixed plate 17, and the first fixed plate 17 is the first driven wheel 18 provides a fixed support foundation, the bottom end of the first fixed plate 17 is fixedly connected to the bott...

Embodiment 2

[0031] Embodiment 6. On the basis of Embodiment 5, in order to ensure that the sorted pills can be directly classified and derived separately, the present invention provides an assembly method to ensure that the pills can be derived separately according to the sorting results. Specifically, The first discharge pipe 63, the second discharge pipe 64 and the first discharge pipe 63, the second discharge pipe 64 and the first discharge pipe 63 are respectively fixedly connected to the lowest points where the first distribution plate 48, the second distribution plate 49 and the third distribution plate 50 intersect with the distribution cylinder 40. Three discharge pipes 65, the first discharge pipe 63, the second discharge pipe 64 and the third discharge pipe 65 are all in an inclined state to facilitate the smooth flow of pills, and the first discharge pipe 63 will Larger pills are exported separately, and the second discharge pipe 64 is separately exported qualified pills, and th...

Embodiment 3

[0032] Embodiment 7. On the basis of Embodiment 6, in order to recycle and process the defective pills produced, the present invention provides a recovery box 67 to ensure that the defective pills can be recycled. Specifically, the recycling The top of the box 67 is fixedly connected with a leak-proof hopper 68 below the outlet of the draft tube 66. The leak-proof hopper 68 can prevent the defective products flowing out of the draft tube 66 from spilling out. The outside of the hopper 68 is fixedly connected with a fixed rod 69. The fixed rod 69 provides a fixed support base for the leak-proof hopper 68. The end of the fixed rod 69 away from the leak-proof hopper 68 is fixedly connected with the recovery box 67. The leak-proof The bottom of the hopper 68 is fixedly connected with two crushing rollers 75, and the two crushing rollers 75 mesh with each other to crush and squeeze the pills. The inside of the two crushing rollers 75 is fixedly connected with a fifth transmission ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com