Full-automatic dispensing system

A fully automatic, dispensing technology, applied in the direction of devices and coatings that apply liquid to the surface, to achieve the effect of stable sealing performance in the warehouse, avoiding position deviation, and convenient opening and closing.

Active Publication Date: 2022-06-10

SUZHOU TERUITE ROBOT CO LTD

View PDF21 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]

The purpose of the present invention is to provide a fully automatic dispensing system, which can prevent the negative pressure from being transferred to the pin shaft and damage the pin shaft when the warehouse body is vacuumed, and can make the door body Under the action of negative pressure, the sealing ring is more compressed to improve the sealing performance, and it also solves the problem that the electronic weighing equipment is difficult to use in a vacuum environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

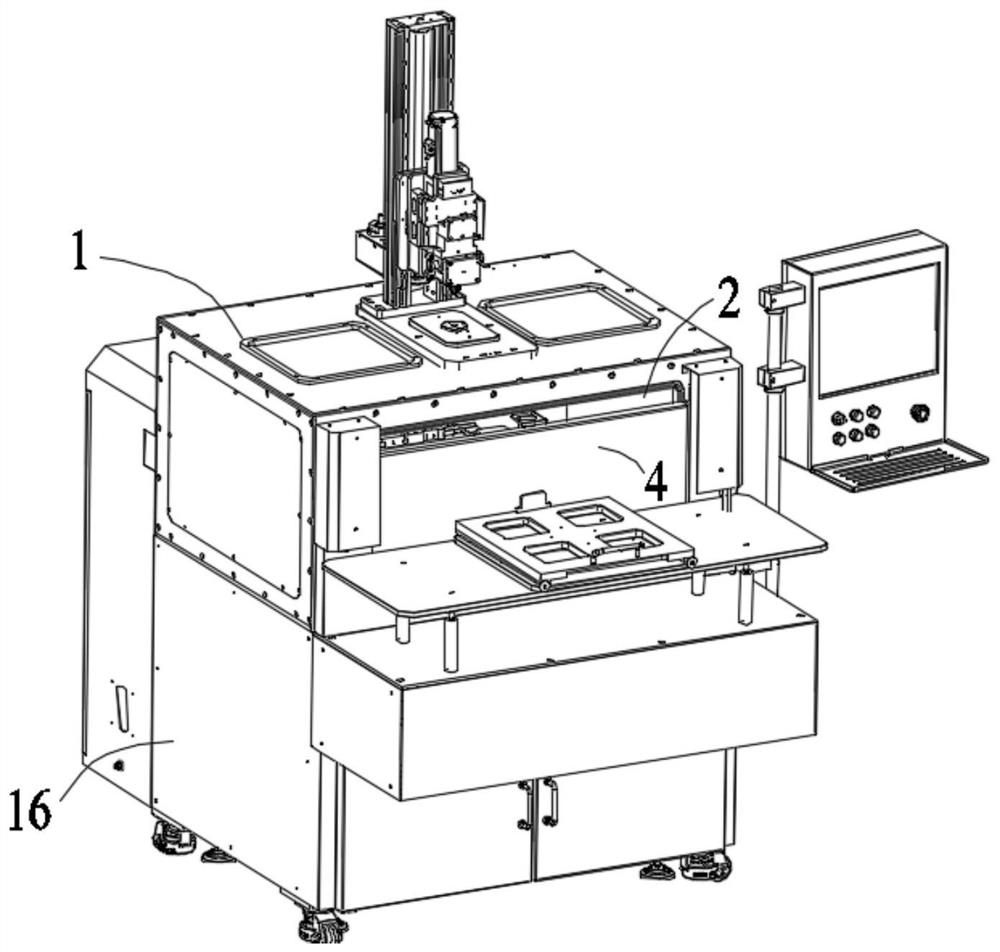

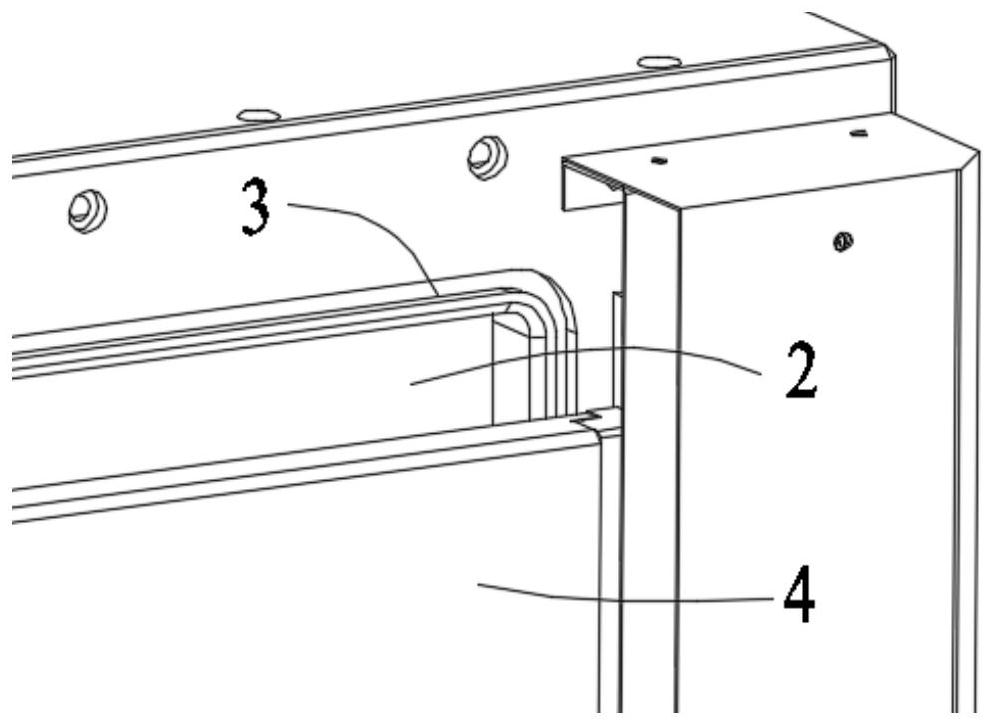

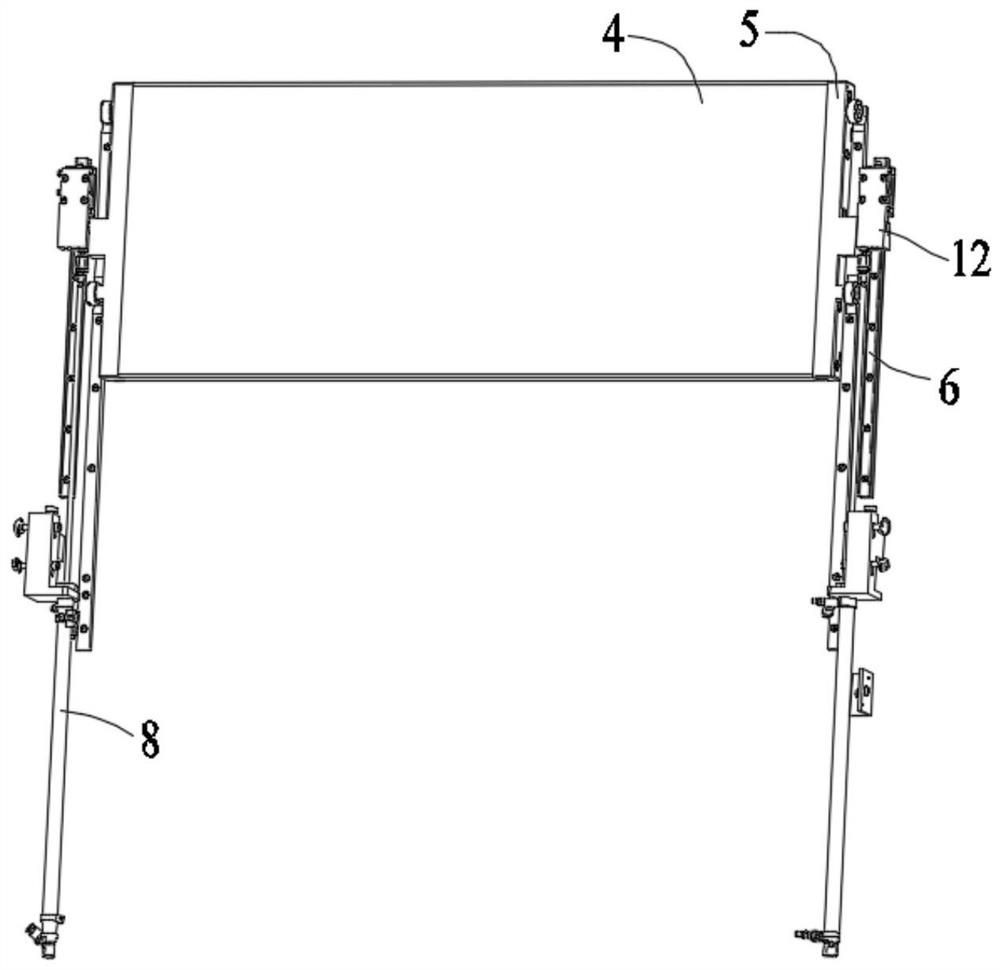

The full-automatic glue dispensing system comprises a sealing bin, a rack, a glue dispensing valve and a workbench, a door opening is formed in the sealing bin, a sealing ring is arranged on the peripheral edge of the door opening, a movable door body is arranged on the front side of the door opening, the left side and the right side of the door body are each provided with a door frame, and the left side and the right side of the door body are each provided with a sealing ring; a linear guide rail is arranged on each of the sealing bins on the left side and the right side of the door opening; and a weighing structure is arranged on the workbench. Through the simple and ingenious structural design, weight metering of liquid in the vacuum environment is achieved, the problem that electronic weighing equipment is difficult to use in the vacuum environment is solved, a telescopic space is provided, when the bin body is vacuumized, the situation that negative pressure is transferred to a pin shaft to damage the pin shaft can be avoided, and the safety of the bin body is improved. And the door body can tightly press the sealing ring under the action of negative pressure, so that the sealing performance of the dispensing mechanism is improved.

Description

technical field [0001] The invention relates to the technical field of glue dispensing, in particular to a fully automatic glue dispensing system. Background technique [0002] At present, most dispensing processes are carried out under normal pressure conditions, but in the production process under normal pressure, there are always cases where gas is mixed into the glue and the product is defective. Therefore, it is necessary to develop a dispensing machine that can work under vacuum conditions. The mechanism is particularly important, but dispensing in a vacuum working environment faces more problems than in a normal pressure environment: how to achieve a good seal of the cavity and how to remove the waste liquid in the dispensing process, there is currently no good solution. Contents of the invention [0003] The purpose of the present invention is to provide a fully automatic dispensing system, which can prevent the negative pressure from being transferred to the pin s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05C5/02B05C11/00

CPCB05C15/00G01G3/00

Inventor 陈晓峰杨春雨

Owner SUZHOU TERUITE ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com