Oxide thin film transistor with improved conductivity and liquid crystal display

A technology of oxide film and oxide conductor, applied in transistors, semiconductor devices, electric solid devices, etc., can solve the problem of uneven display, and achieve the effect of solving uneven display, improving conductivity, and high precision of graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

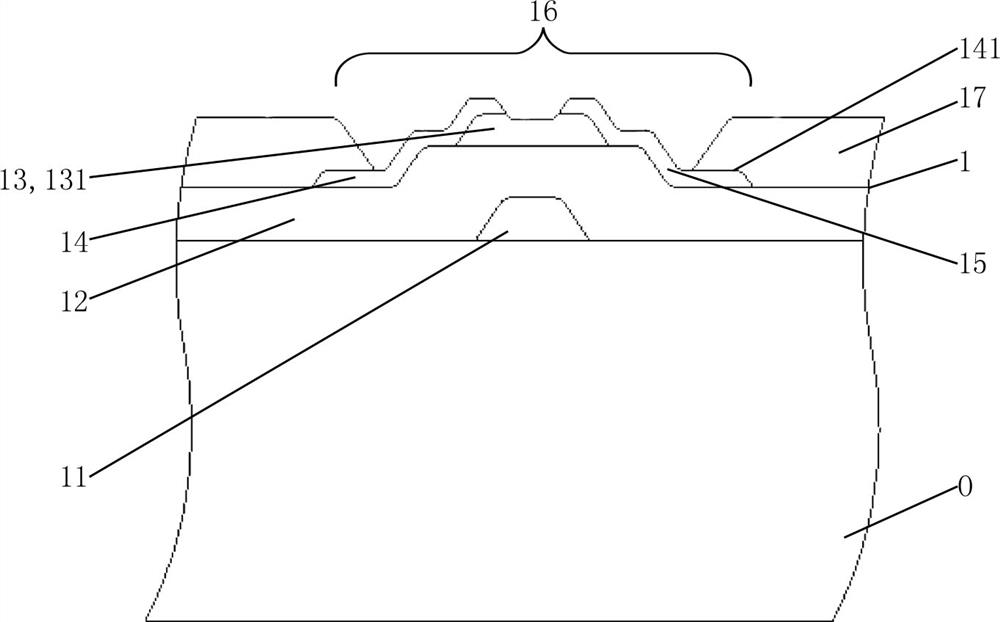

[0035] as Figure 1As shown, such an improved conductivity of the oxide thin film transistor 1, comprising a gate 11 and an insulating layer 12 disposed on the substrate 0, and an active layer 13, a source 14 and a drain 15, the gate 11 is covered by the insulating layer 12, the active layer 13, the source 14, the drain 15 are disposed on the upper surface of the insulating layer 12, the source 14, the drain 15 relatively set; The active layer 13 is an oxide semiconductor layer 131, the source 14, the drain 15 are patterned by the oxide conductor layer 141, the source 14, the drain 15 and the active layer 13 are superimposed to form a conductive channel 16; Oxide thin film transistor 1 further comprises a metal circuit 17, the metal circuit 17 is disposed on the insulation layer 12 and is located on the periphery of the oxide conductor layer 141, and the metal line 17 is connected to the source 14, the drain 15 is mated.

[0036] Active layer 13 is an oxide semiconductor layer 131,...

Embodiment 2

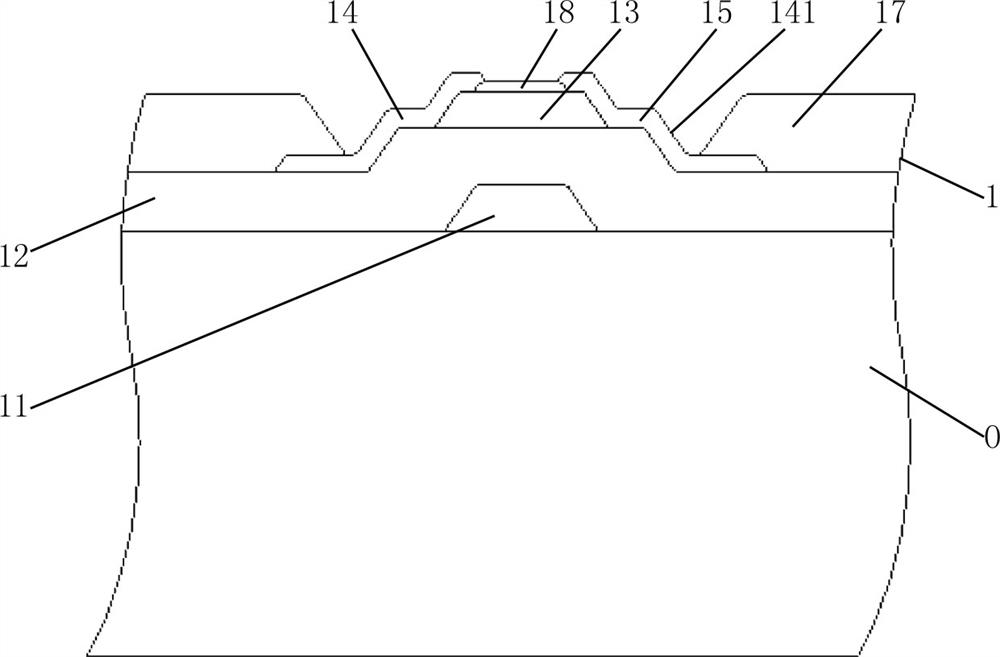

[0043] reference Figure 2 , in the case where other moieties are the same as Example I, the difference is that: in the present embodiment, the oxide thin film transistor 1 adopts a staggered channel etched structure, the source 14, the drain 15 portion is superimposed on top of the active layer 13; Oxide thin film transistor 1 further comprises a protective layer 18, the protective layer 18 is covered on the upper surface of the active layer 13 and is between the source 14 and the drain 15; The protective layer 18 is a polymer coating or an inorganic coating such as silicon oxide and silicon nitride.

Embodiment 3

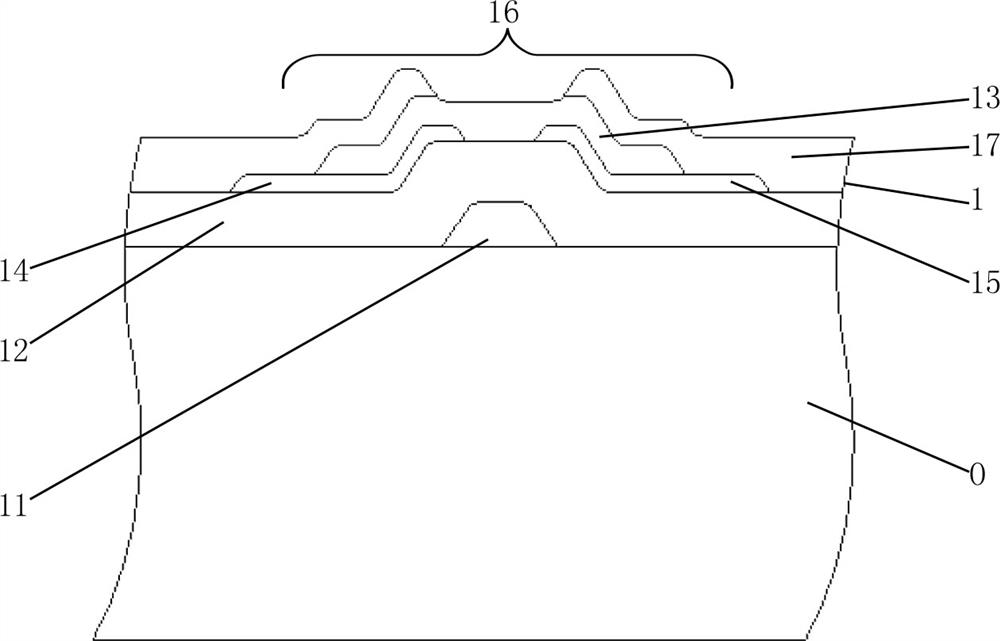

[0045] reference Figure 3 , in the case of other moieties are the same as Example I, the difference is that: in the present embodiment, the oxide thin film transistor 1 adopts a coplanar channel etched structure, the source 14, the drain 15 portion of the pad is located at the bottom of the active layer 13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com