Sludge drying equipment for environmental pollution abatement

A technology for drying equipment and sludge, applied in the field of environmental pollution control, can solve the problems of reducing drying efficiency, increasing drying time, poor drying effect, etc., and achieving the effects of improving drying efficiency, improving uniformity, and avoiding stacking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

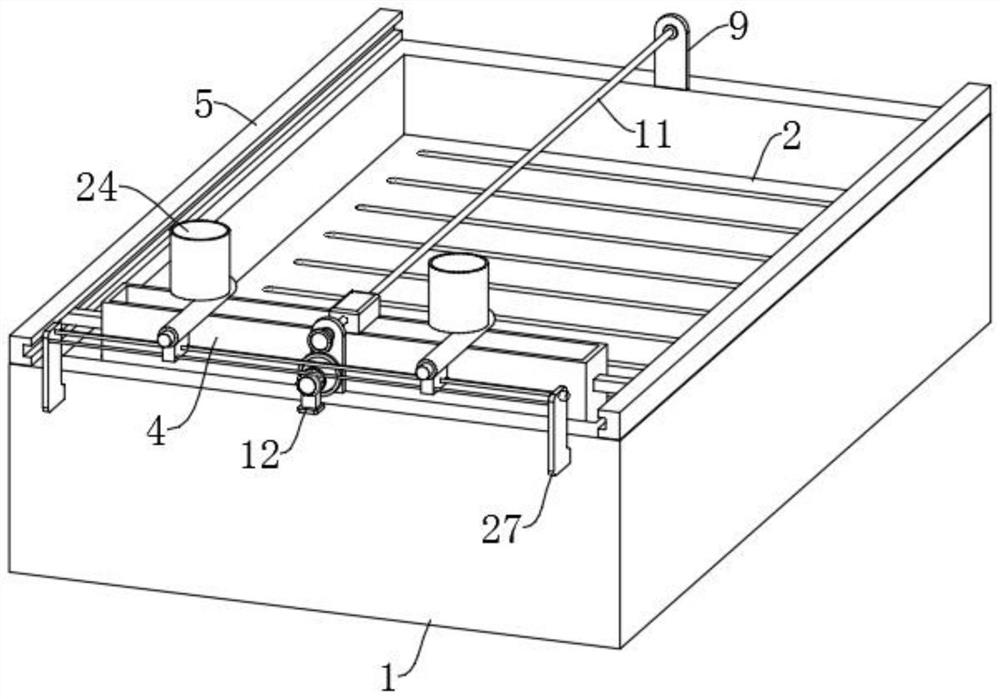

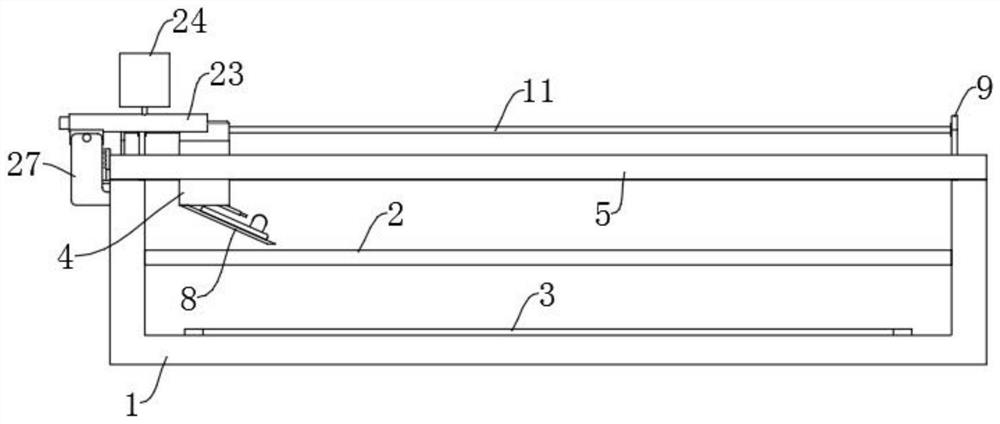

[0023] Reference Figure 1-4, a kind of environmental pollution control with silt drying equipment, including the box 1, the box 1 is fixed with a mesh plate 2, the bottom of the box 1 is fixed to install a number of equally spaced distribution of the heating plate 3, the top of the box 1 is provided with a transfer box 4, the top of the box 1 is fixed on both sides of the slide 5, the transfer box 4 is fixed on both sides of the slider 6, the slide 6 is set in the slide 5, the bottom of the transfer box 4 is equipped with an outlet 7, and the bottom of the transfer box 4 is fixed with a deflector plate 8. The bottom of the box 1 is fixedly installed with two spaced side plates 9, the top of the transfer box 4 is fixed with a top block 10, further comprising a drive mechanism, the drive mechanism is connected to the top block 10 and can drive the transfer box 4 along the slide 5. The drive mechanism comprises a first screw 11, the first screw 11 through the top block 10 and is conn...

Embodiment 2

[0026] Reference Figure 1-4 , as another preferred embodiment of the present invention, the difference with Example 1 is that the deflector plate 8 is provided with a accumulation mechanism, the accumulation mechanism is disposed on the upper end face of the deflector plate 8 and connected to the transfer box 4. The accumulation mechanism comprises two side baffles 15, two side baffles 15 are fixed on both sides of the upper end surface of the deflector plate 8, the side baffle 15 is fixed with a support plate 16, the two support plates 16 can be rotated between the mounted shaft 17, the lower baffle 18 is fixed on the hinge 17, the hinge 17 end runs through the support plate 16, the reel 17 end sleeve is provided with a reed 19, and the two ends of the reed 19 are fixed on the reel 17 and the support plate 16. The accumulation mechanism further comprises a positioning mechanism, the positioning mechanism is fixed at the end of the shaft 17. Positioning mechanism comprising a cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com