Automatic spool packaging line

A packaging line and automatic line technology, applied in packaging, packaging machines, packaging protection, etc., can solve the problems of spool spraying, error-prone, affecting quality, etc., and achieve the effect of ensuring accuracy and reducing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] All features disclosed in this specification, or all disclosed steps in a method or process, may be combined in any way except mutually exclusive features and / or steps.

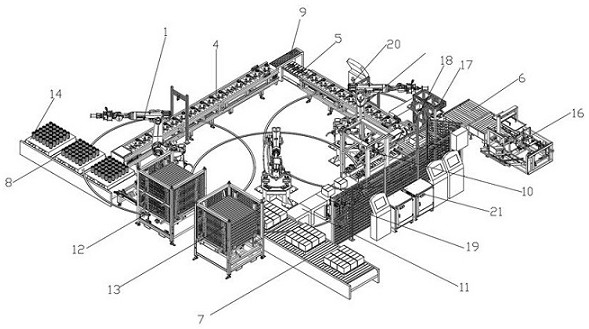

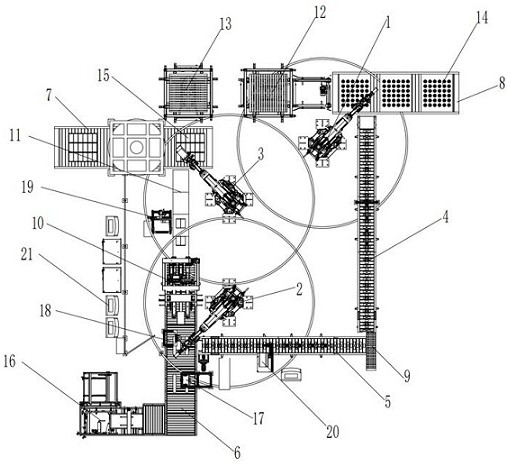

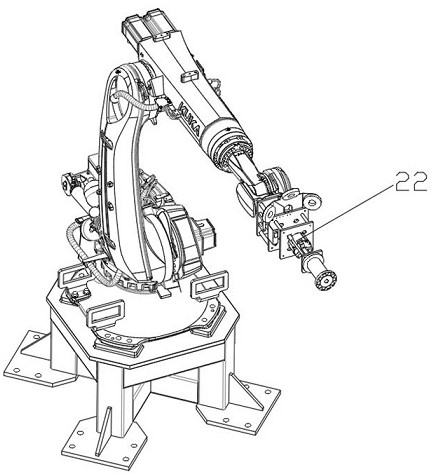

[0031] like Figure 1-Figure 2 As shown, an automatic spool packaging line of the present invention includes a spool manipulator 1, a packing manipulator 2, a palletizing manipulator 3, a spool assembly line 4, a station assembly line 5, a carton assembly line 6 and a finished pallet assembly line 7;

[0032] One end of the spool assembly line 4 is provided with a spool tray assembly line 8, and the other end is provided with a manual detection roller table 9; There is a case sealing machine 10, and a labeling table 11 is arranged on one side of the case sealing machine 10; a finished pallet assembly line 7 is arranged at one end of the labeling table 11, and passes through the spool tray assembly line 8, the spool assembly line 4, the manual inspection roller table 9, and the carton assembly line 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com