Step green belt construction method

A construction method and technology for green belts, which are applied in field preparation methods, botanical equipment and methods, excavation, etc., can solve problems such as inconvenience in material transfer, and achieve the goal of improving material transfer efficiency, facilitating flexible application, and improving construction efficiency and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

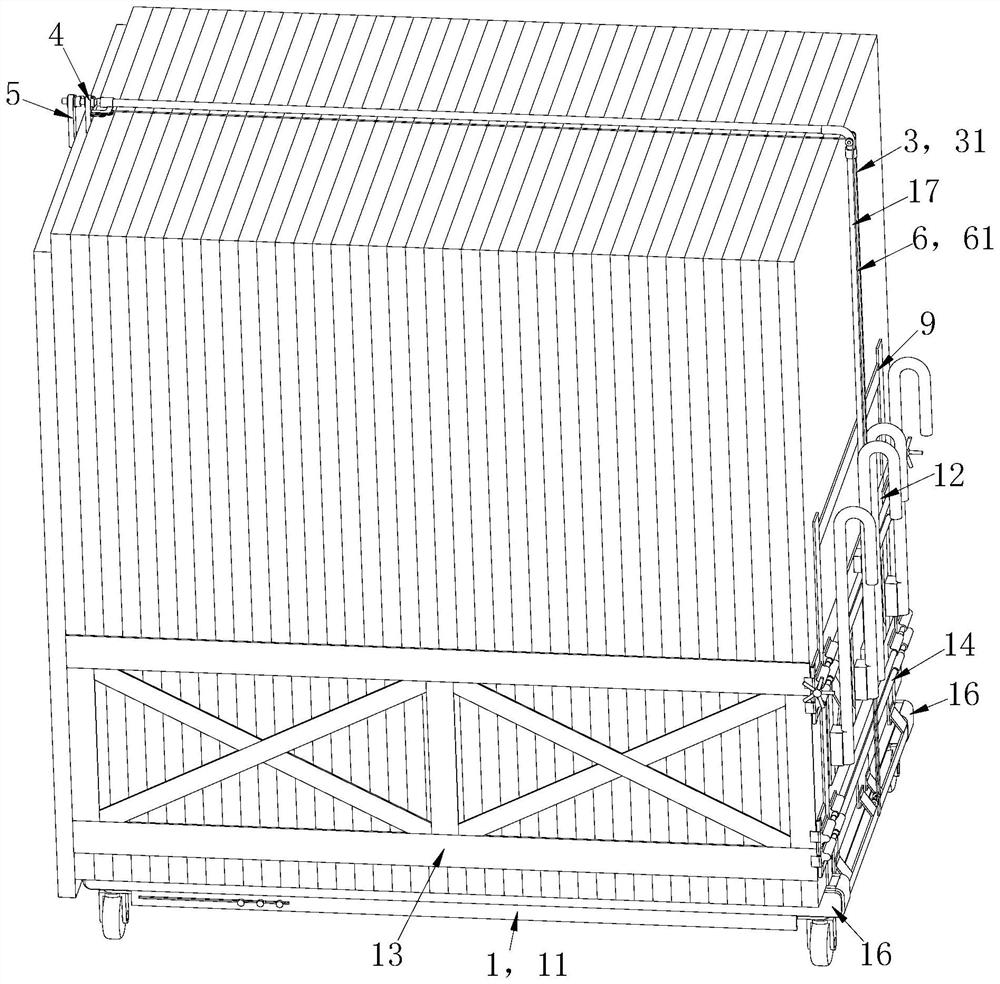

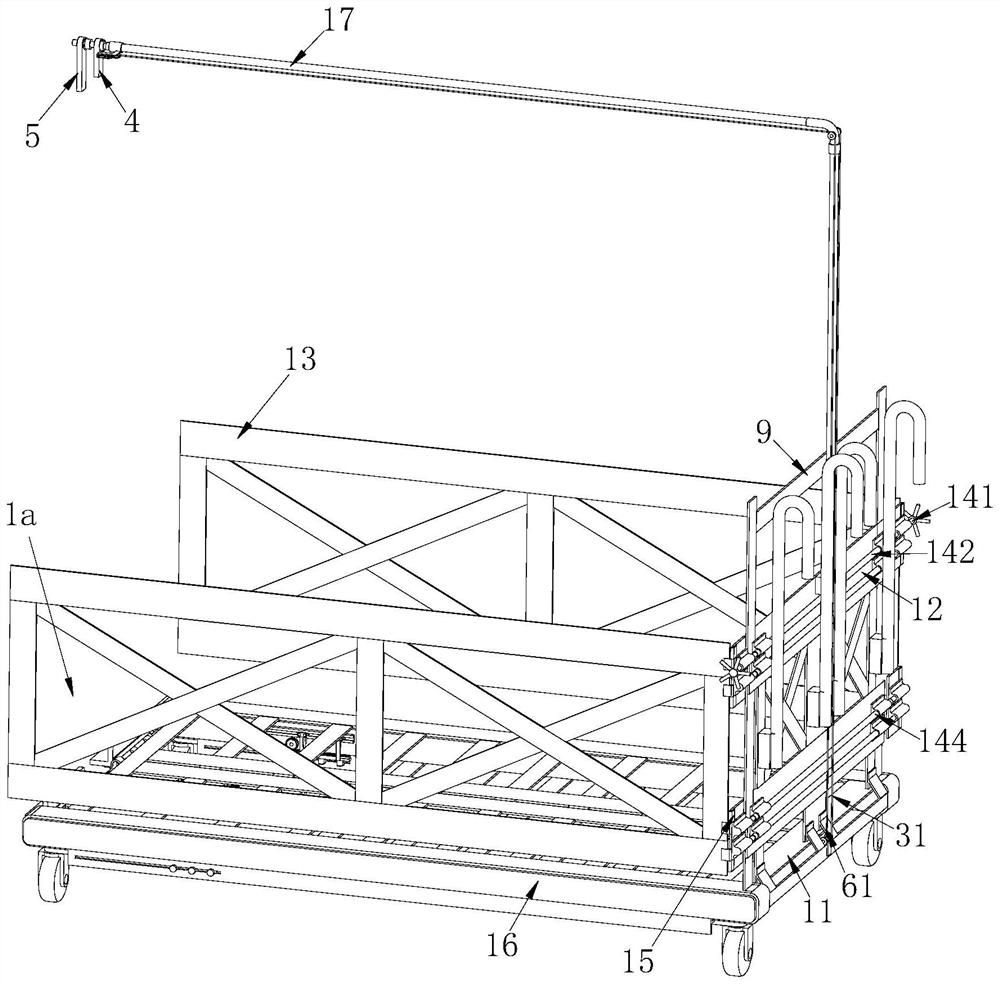

Image

Examples

Embodiment 3

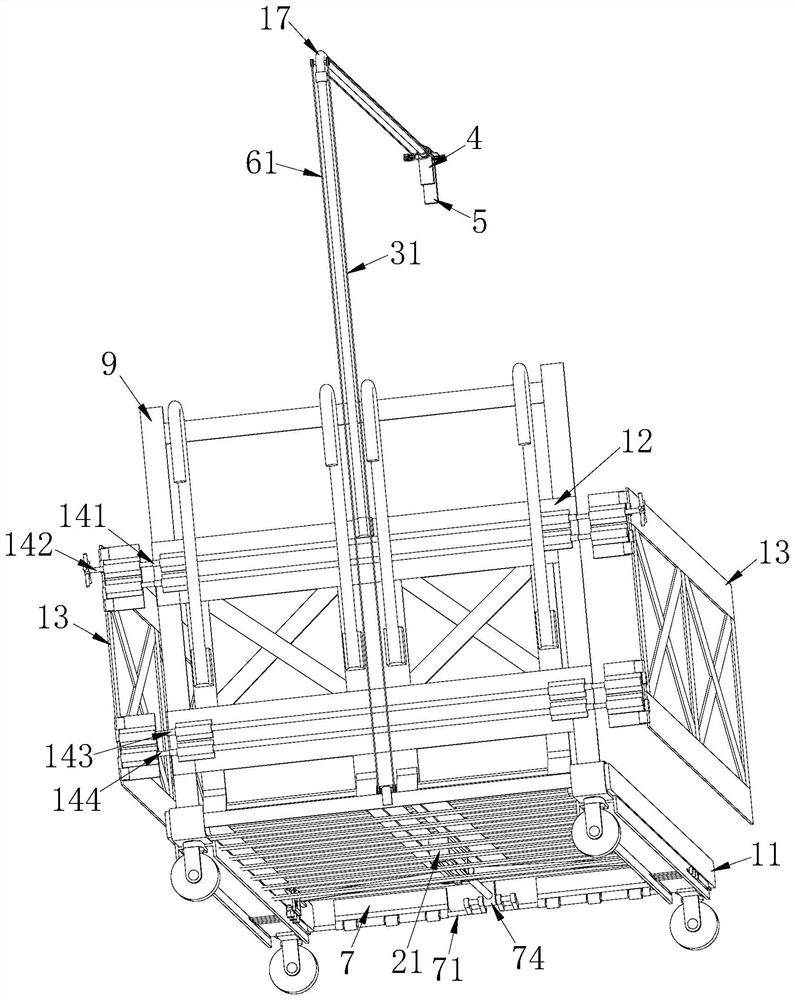

[0078] The third embodiment has the following process:

[0079] The extension end of the power telescopic rod 21 is in the initial stage of the extension stroke, since the rod spring 81 is in a stretched state, at this time, the inner end of the eccentric rod 73 is located at the bottom of the rail groove of the vertical rail 74, and the vertical rail 74 cannot As a result, it is impossible to provide a stroke for the downward rotation of the inner end of the eccentric rod 73 , so that the movable end of the elastic telescopic rod 8 is locked by the cooperation of the vertical rail 74 and the eccentric rod 73 . Therefore, the movable end of the elastic telescopic rod 8 is in a static state, and the fixed end of the elastic telescopic rod 8 moves to the outer end of the movable end, so that the elastic telescopic rod 8 is in a state of continuous contraction as a whole. During this process, the fixed end of the elastic telescopic rod 8 will drive the ratchet rack 23 to meet fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com