Method for recycling lithium ion battery negative electrode slurry

A technology for lithium-ion batteries and negative electrode slurry, which is applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of high energy consumption, single recycling method, and inactivation of binders, and achieves energy reduction. Consumption, simplified recycling process, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

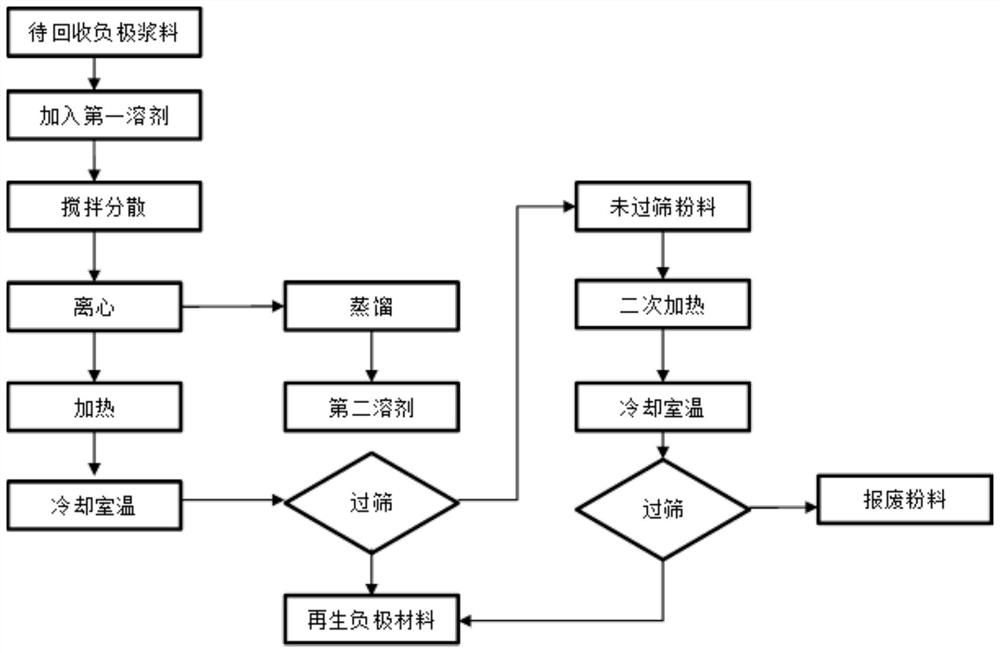

[0078] This embodiment provides a method for recycling negative electrode slurry of a lithium ion battery, see figure 1 , the method includes:

[0079] (1) Add 0.5kg of NMP to 5kg of the negative electrode slurry to be recovered, place it in a stirring tank and stir, the stirring revolution speed is 15rpm, the dispersing speed is 900rpm, the time is 2h, and the discharge temperature is 23 ℃ to obtain a mixed slurry material;

[0080] (2) transferring the mixed slurry described in step (1) to a centrifuge for centrifugation, the centrifugal speed is 10000rpm, and the time is 1h to obtain the upper layer liquid and the lower layer slurry;

[0081] (3) distilling the upper layer liquid described in step (2) to obtain a high-purity NMP solvent, heating the lower layer slurry at 550 ° C for 30min, the heating method is high temperature baking, then passing through a 200-mesh sieve, collecting and passing through the sieve The particles of the net are obtained to obtain a regenera...

Embodiment 2

[0084] This embodiment provides a method for recycling negative electrode slurry of a lithium ion battery, see figure 1 , the method includes:

[0085] (1) Add 0.7kg of NMP to 5kg of the negative electrode slurry to be recovered, place it in a stirring tank and stir, the stirring revolution speed is 10rpm, the dispersing speed is 800rpm, the time is 2.5h, and the discharge temperature is 20 ° C to obtain the mixing slurry;

[0086] (2) transferring the mixed slurry described in step (1) to a centrifuge for centrifugation, the centrifugal speed is 9000rpm, and the time is 1.5h to obtain the upper layer liquid and the lower layer slurry;

[0087] (3) distilling the upper layer liquid described in step (2) to obtain a high-purity NMP solvent, heating the lower layer slurry at 600 ° C for 25min, the heating method is high-temperature baking, then passing through a 200-mesh sieve, collecting and passing through the sieve The particles of the net are obtained to obtain a regenerat...

Embodiment 3

[0090] This embodiment provides a method for recycling negative electrode slurry of a lithium ion battery, see figure 1 , the method includes:

[0091] (1) Add 0.3kg of NMP to 5kg of the negative electrode slurry to be recovered, place it in a stirring tank and stir, the stirring revolution speed is 20rpm, the dispersing speed is 1000rpm, the time is 1.5h, and the discharge temperature is 26 ℃ to obtain the mixing slurry;

[0092] (2) transferring the mixed slurry described in step (1) to a centrifuge for centrifugation, and the rotating speed of the centrifugation is 11000rpm and the time is 0.5h to obtain the upper layer liquid and the lower layer slurry;

[0093] (3) distilling the upper layer liquid described in step (2) to obtain a high-purity NMP solvent, heating the lower layer slurry at 500 ° C for 35min, the heating method is high temperature baking, then passing through a 200-mesh sieve, collecting and passing through the sieve The particles of the net are obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com