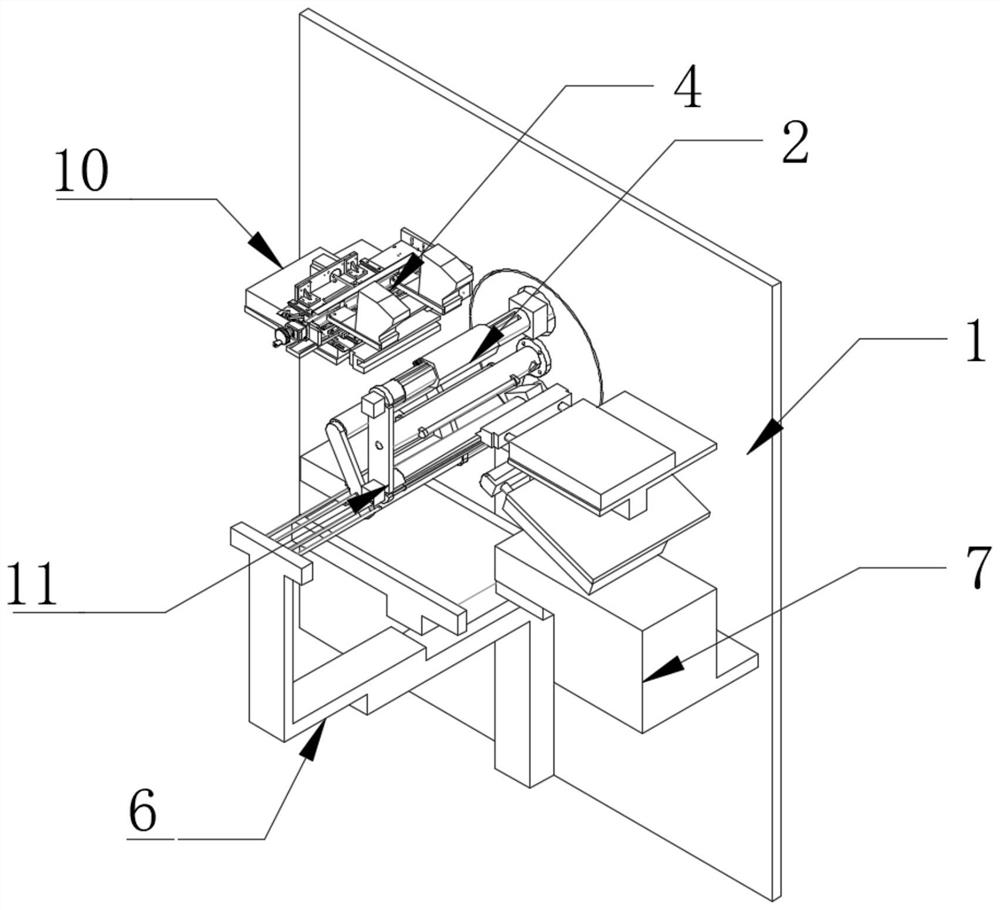

Winding machine equipment adopting 3D (three-dimensional) line scanning camera and tab folding detection method

A detection method and winding machine technology, applied in the direction of winding capacitor machines, optical devices, measuring devices, etc., can solve the problems of tab forming quality influence, inconvenient tab detection, unfavorable processing and production, etc., to achieve powerful self-learning The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

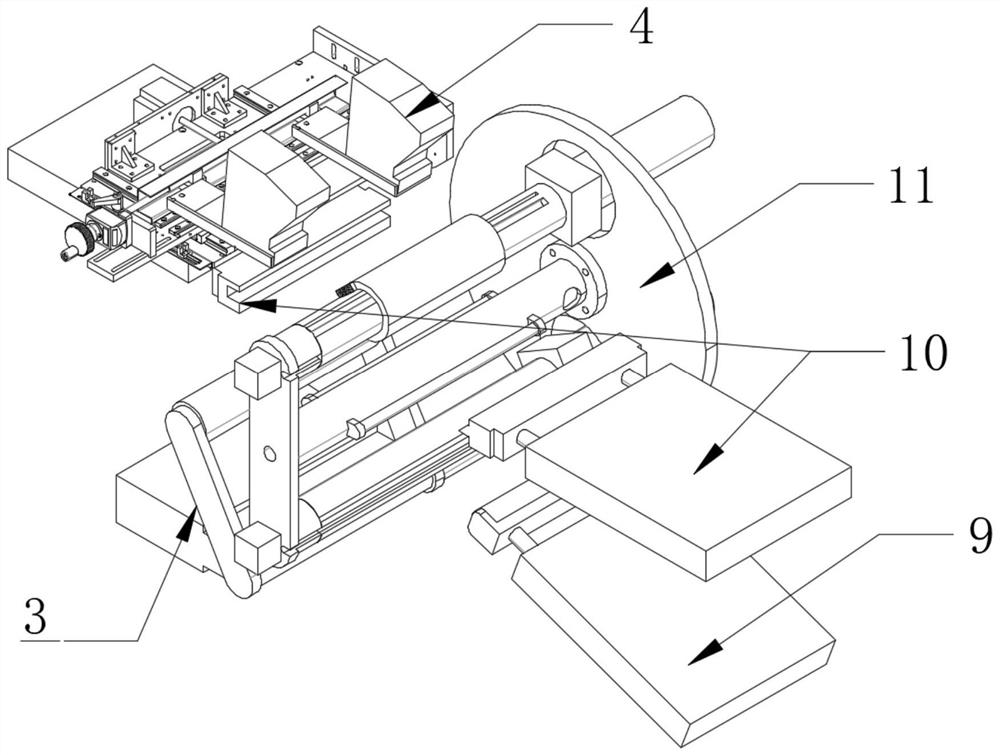

[0040] The method for detecting the folding of the tabs of the winder equipment using a 3D line scan camera includes the following steps:

[0041] S1. The 3D line scan camera 4 takes the picture of the electrode core position, analyzes the two-dimensional distance between the material or the dividing line and the marked position through the PC machine vision system, and realizes the real-time display of the scatter connection curve and icon on the display;

[0042] S2. The PC machine vision system processes the dislocation value of the cell, and calculates the maximum, minimum and average value of the dislocation value between each bare cell layer and the layer, as well as the folding degree of each tab, etc.;

[0043] S3. During the winding process, when the dislocation value exceeds the set warning range, the PC machine vision system sends out an alarm message and sends the alarm signal to the winder. The operator checks and adjusts the dislocation value of the pole piece an...

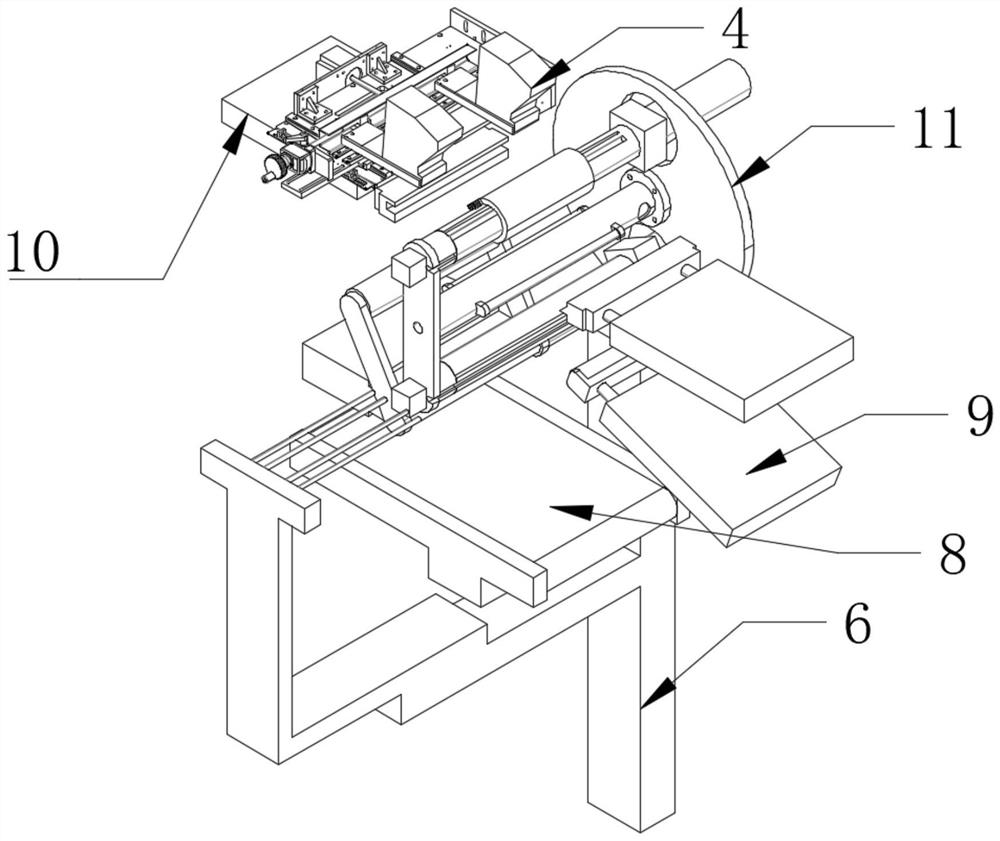

Embodiment 2

[0046] The method for detecting the folding of the tabs of the winder equipment using a 3D line scan camera includes the following steps:

[0047] S1. The 3D line scan camera 4 takes the picture of the electrode core position, analyzes the two-dimensional distance between the material or the dividing line and the marked position through the PC machine vision system, and realizes the real-time display of the scatter connection curve and icon on the display;

[0048] S2. The PC machine vision system processes the dislocation value of the cell, and calculates the maximum, minimum and average value of the dislocation value between each bare cell layer and the layer, as well as the folding degree of each tab, etc.;

[0049] S3. During the winding process, when the dislocation value exceeds the set warning range, the PC machine vision system sends out an alarm message and sends the alarm signal to the winder. The operator checks and adjusts the dislocation value of the pole piece an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com