Three-phase combined transformer

A combined transformer and transformer technology, applied in the field of transformer manufacturing, can solve the problem that the large-capacity integrated transformer cannot meet the transportation conditions in remote mountainous areas, etc., and achieve the effect of ensuring the quality of on-site installation, reducing the workload, and ensuring the amount of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

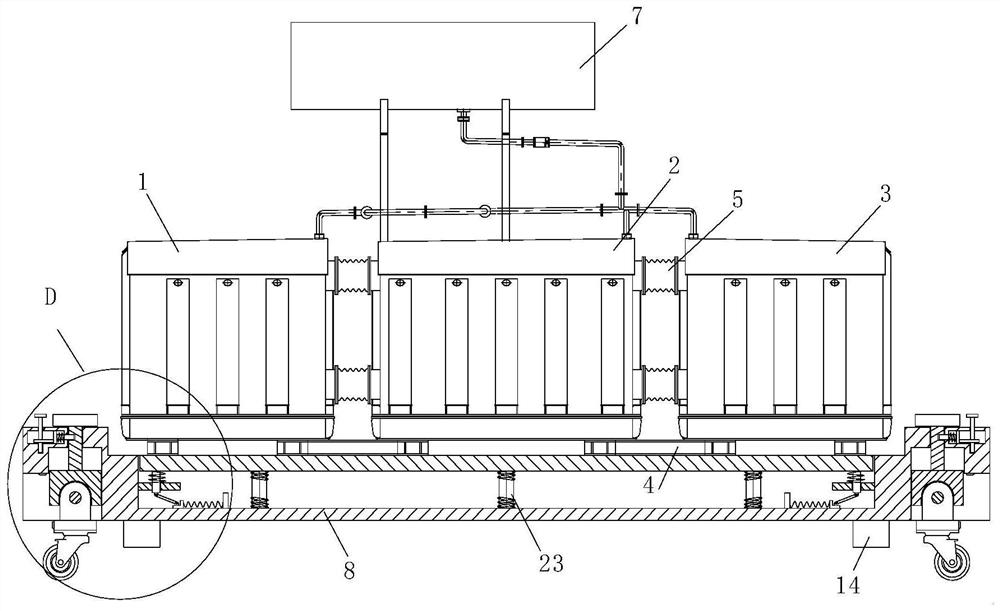

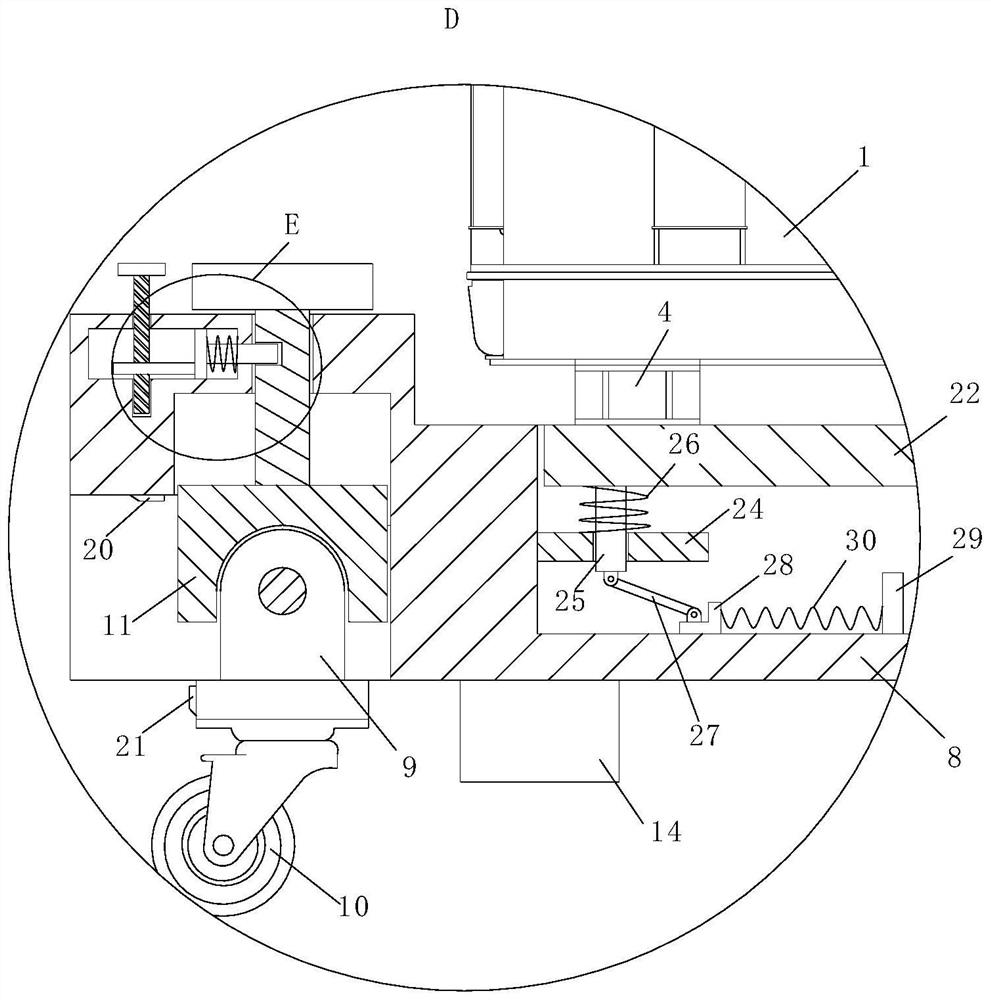

[0028] see Figure 1-6As shown, a three-phase combined transformer includes an A-phase transformer 1, a B-phase transformer 2 and a C-phase transformer 3; the bottoms of the A-phase transformer 1, B-phase transformer 2 and C-phase transformer 3 are all fixed with steel chassis 4; a bellows 5 is fixedly connected between the A-phase transformer 1 and the B-phase transformer 2, and the bellows 5 is provided with a lead wire, so that the B-phase transformer 2 and the C-phase transformer 3 are electrically connected; the A bellows 5 is also fixed between the B-phase transformer 2 and the C-phase transformer 3, and the bellows 5 is provided with a lead wire, so that the B-phase transformer 2 and the C-phase transformer 3 are electrically connected; A three-phase integrated on-load tap-changer 6 is provided; an oil conservator 7 is fixed on the top of the B-phase transformer 2, and the oil conservator 7 is connected to the interior of the A-phase transformer 1, B-phase transformer 2...

Embodiment 2

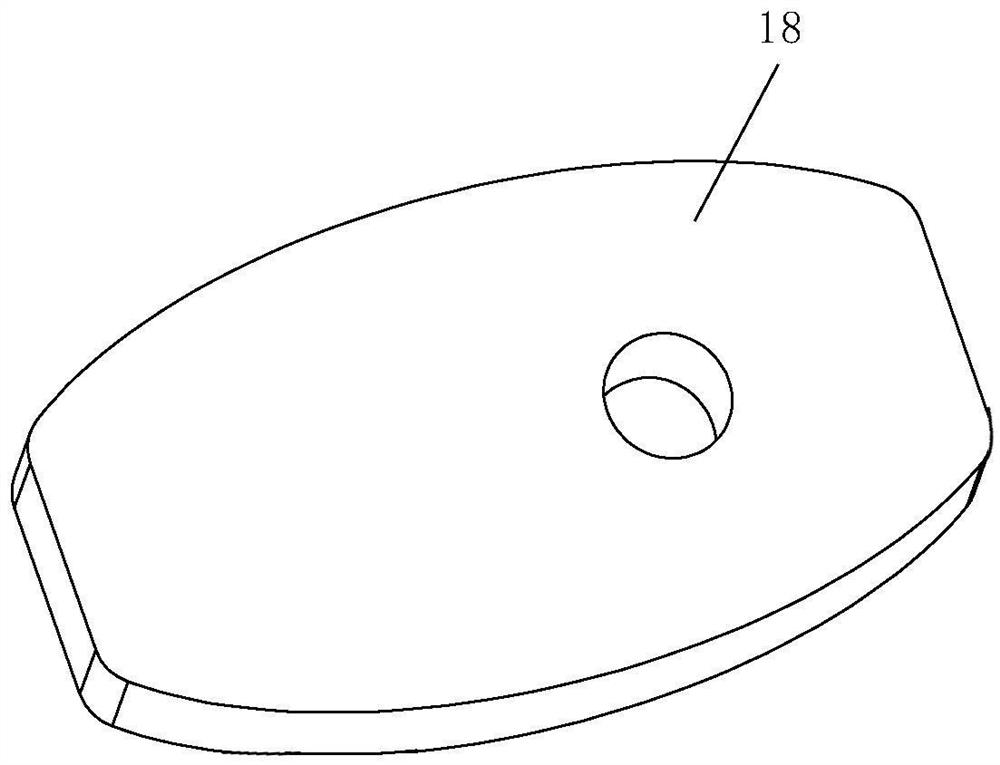

[0037] see Figure 7 As shown in Comparative Example 1, as another embodiment of the present invention, a handle 31 is fixed to the top of the threaded rod 17; during operation, the handle 31 is provided to facilitate the rotation of the threaded rod 17. When the rod 17 rotates downward, it will make the cam 18 squeeze the No. 2 plate 15 to realize the fixation of the No. 1 rod 12. When the threaded rod 17 rotates upward, it will make the cam 18 leave the No. 2 plate 15, so as to realize the fixing of the No. 1 rod 12. Reset of the second lever 16.

[0038] Working principle: In order to facilitate the movement of the three-phase transformer, a jack can be used at the bottom of the base and raised a certain distance, and then the universal wheel 10 is rotated so that the wheel of the universal wheel 10 is in contact with the ground. Push down the push plate 13, so that the push plate 13 drives the No. 1 rod 12 and the positioning block 11 to move downward, so that the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com