Gas cylinder filling process safety detection method and system

A technology of process safety and detection method, which is applied in the direction of container filling method, container discharge method, transportation and packaging, etc. It can solve the problems of difficult application, small change in the size of gas cylinder filling and discharging, and low reliability of safety detection results. , to achieve the effect of improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

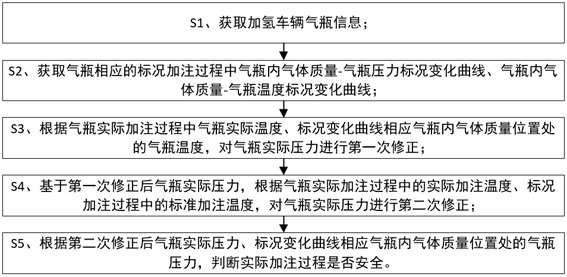

refer to figure 1 As shown, the present embodiment provides a safety detection method for a gas cylinder filling process, comprising the steps of:

S1. Obtain the gas cylinder information of the hydrogenation vehicle;

S2. Obtain the gas quality in the gas cylinder-gas cylinder pressure standard condition variation curve, and the gas quality in the gas cylinder-gas cylinder temperature standard condition variation curve during the filling process of the gas cylinder corresponding standard conditions;

S3. According to the actual temperature of the gas cylinder during the actual filling process of the gas cylinder, and the gas cylinder temperature at the position of the gas mass in the gas cylinder corresponding to the change curve of the standard condition, the actual pressure of the gas cylinder is corrected for the first time;

S4. Based on the actual pressure of the gas cylinder after the first correction, according to the actual filling temperature in the actual filling pr...

Embodiment 2

refer to Figure 4 As shown, this embodiment provides a gas cylinder filling process safety detection system, based on the gas cylinder filling process safety detection method described in the first embodiment, including a gas cylinder information acquisition module, a standard condition change curve acquisition module, a first correction module, a second correction module, a judgment module, and a gas cylinder filling information acquisition module;

The gas cylinder information acquisition module, the standard condition change curve acquisition module, the first correction module, the second correction module and the judgment module are connected in sequence, the standard condition change curve acquisition module is also connected with the judgment module, and the first correction module is also connected with the gas cylinder filling Information acquisition module connection;

The gas cylinder filling information acquisition module is used to obtain the gas quality in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com