Oil reservoir top wing linkage stepped three-dimensional gas injection development method

A stepped, reservoir technology, applied in the development of fluids, earth-moving drilling, climate sustainability, etc., can solve the problems of unsatisfactory development economy, limited development speed, slow gas injection effect, etc. The effect of development economic guarantee, high gas sweep efficiency, and reduced control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0125] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solutions of the present invention are now described in detail below with reference to the following specific examples, but should not be construed as limiting the scope of implementation of the present invention.

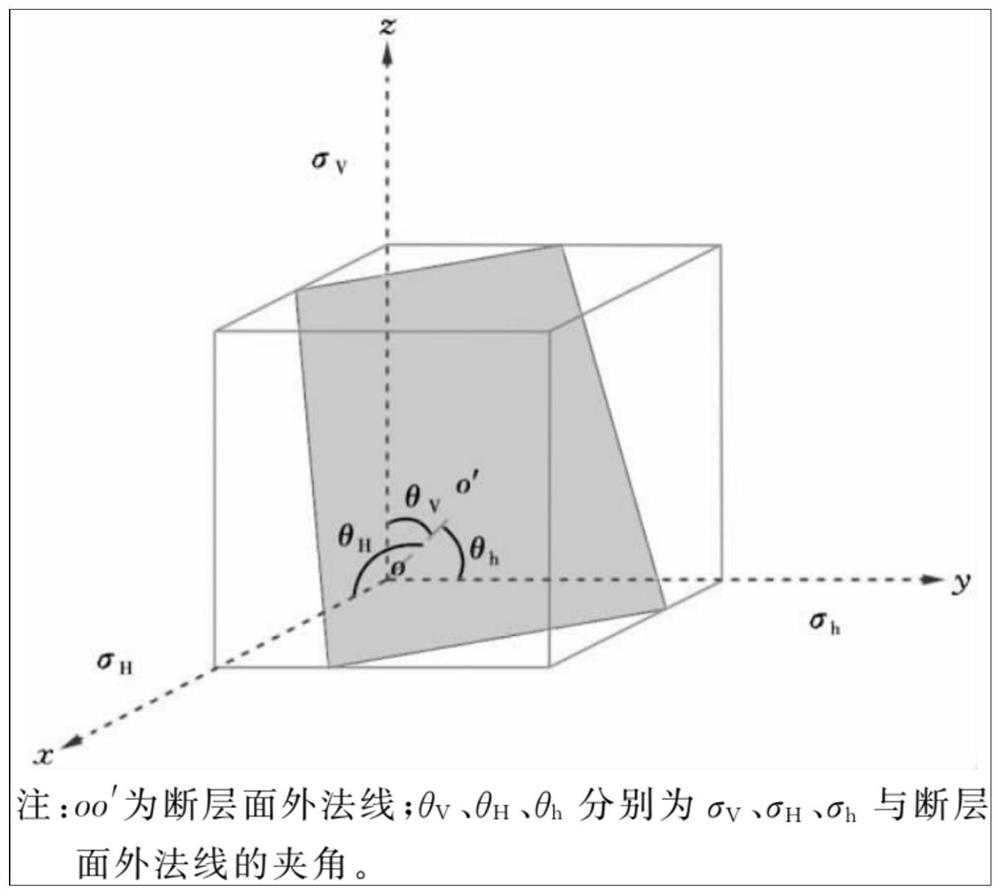

[0126] This example takes the design of the top-flap linked stepped three-dimensional gas injection development plan of the PW giant fractured conglomerate reservoir as an example, and describes in detail the top-flap linked stepped three-dimensional gas injection development method of the reservoir provided by the present invention. The method includes: The following specific steps:

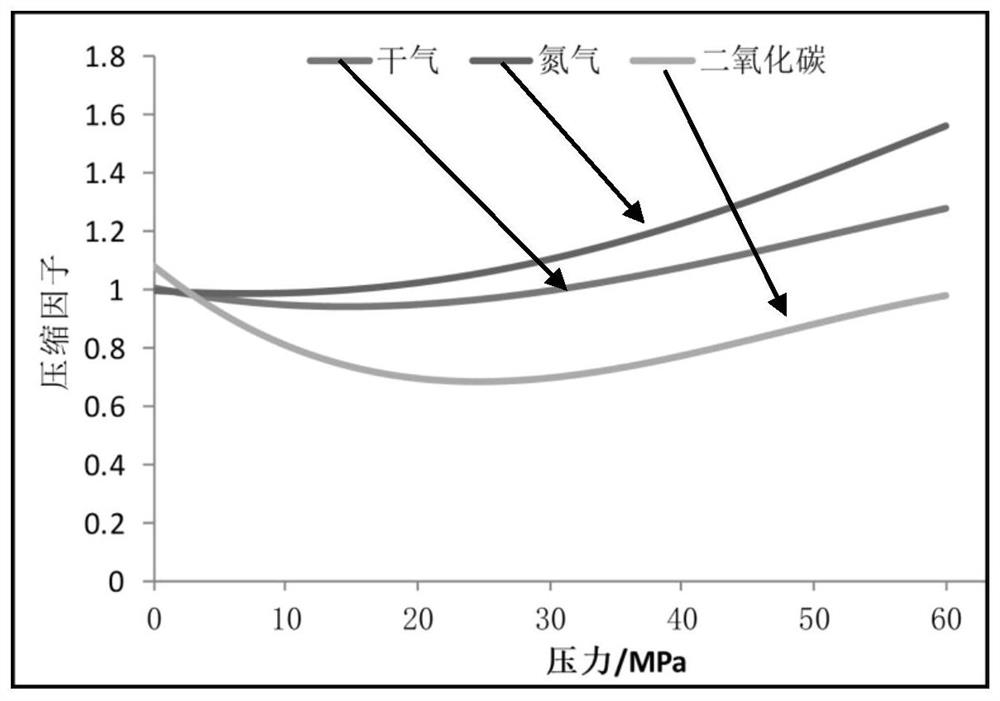

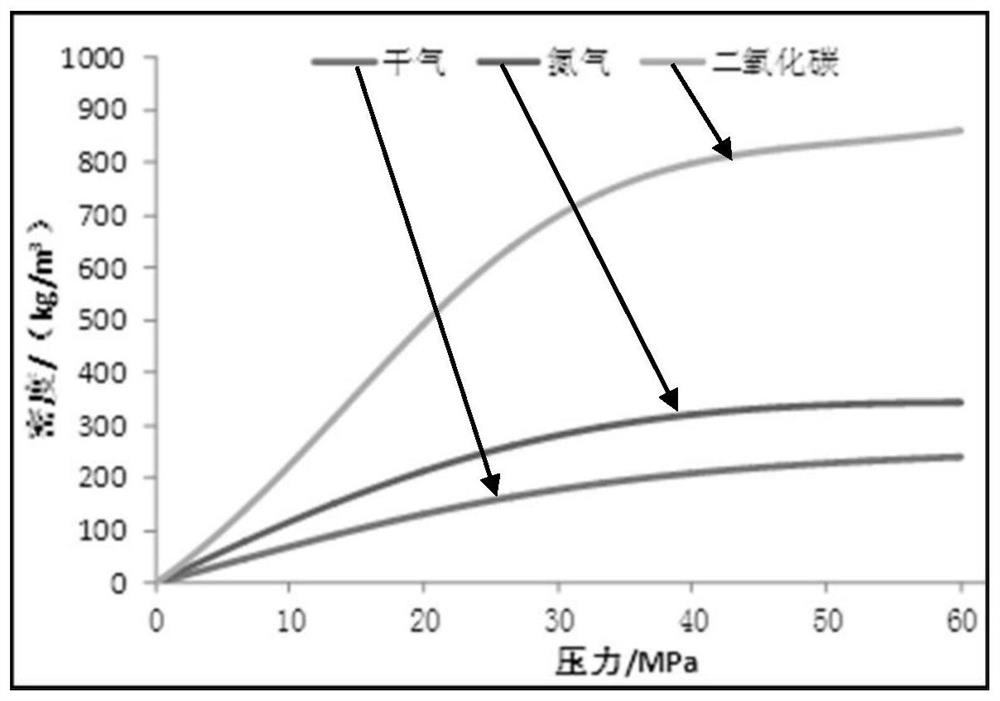

[0127] (1) Determine the basic parameters of the reservoir: large reserves (>50 million tons in the test area), poor pressure retention (>65%), high oil-bearing height (>600m), thick oil layer (>400m), and an average porosity of 10 %, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com