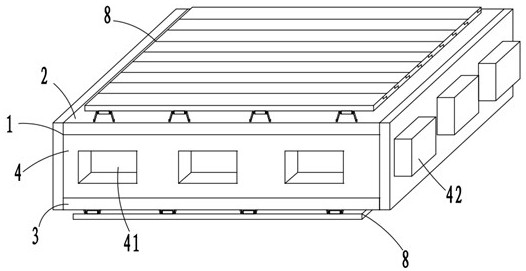

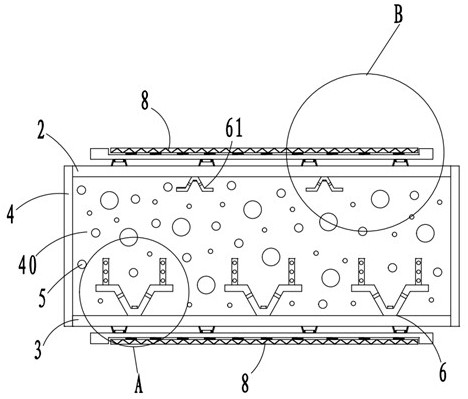

Anti-shelling non-combustible thermal insulation system for aircraft testing

A technology for aircraft testing and thermal insulation systems, applied in aircraft component testing, thermal insulation, construction, etc., can solve the problems of low bonding strength between PIR materials and stainless steel, low bonding strength between inner panels and core materials, and low service life of thermal insulation boards, etc. problems, to achieve the effect of convenient later maintenance, reduce weight and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

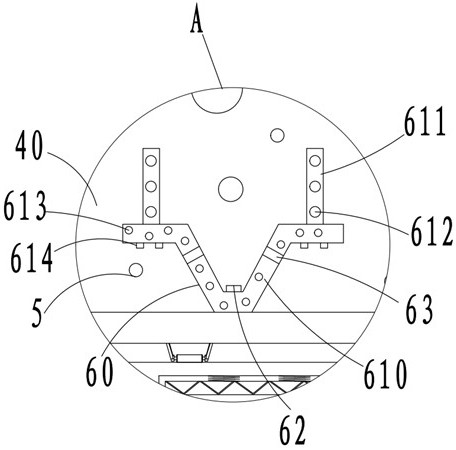

[0019] Among them, the thickness of the fastening frame is 1500mm, the number of the first π-type embedded parts is controlled at 2, the number of the second π-type embedded parts is controlled at 3, and the thickness of the inner panel and the outer panel is 1200mm; The width of the seam between two adjacent thermal insulation boards is 15mm; the number of horizontal anti-collision boards located on the same inner panel or outer panel is controlled to be 10.

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com