Method for preparing active mineral admixture through suspension roasting of industrial solid waste

A technology of active minerals and industrial solid waste, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of no comprehensive utilization method, human health hazards, low activity of vanadium slag, etc. The effect of large, small environmental pollution and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

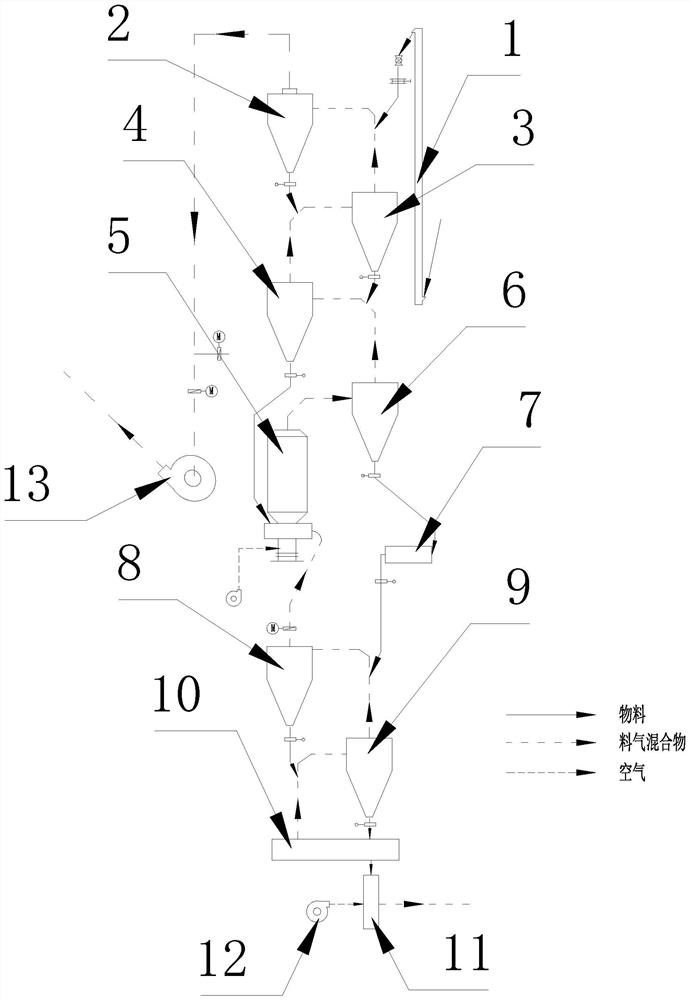

[0022] The direction of material flow during production: vanadium slag, stone coal and limestone are mixed evenly according to the proportion and then sent to the first preheating pipe by elevator 1, and the mixture in the first preheating pipe enters P1 suspension preheater 2 in turn with the hot air flow , P2 suspension preheater 3, P3 suspension preheater 4, complete the preheating, decomposition and 10% solid phase reaction of the mixture; The pipeline of the discharge port enters the roasting furnace 5 for sintering. After the mixture is sintered in the solid phase of 70-80% in the roasting furnace 5, the sintered material enters the gas-solid separator 6 with the hot air flow through the pipeline for gas-solid separation. , the gas phase after gas-solid separation is extracted by the high-temperature fan 13 through the pipeline and then sent to the waste gas treatment system for processing. The solid-phase reaction is completed in the rotary reactor 7, and the active min...

Embodiment 2

[0025]A conveying pump 11 is arranged below the discharge port of the heat exchanger 10, a pipeline is arranged between the conveying pump 11 and the discharge port of the heat exchanger 10, a roots blower 12 is arranged on one side of the conveying pump 11, and the roots blower 12 and the conveying pump 11 A pipeline is set between the air inlets of the heat exchanger 10, a C1 cooler 9 is set above the feed opening of the heat exchanger 10, a pipeline is set between the discharge opening of the C1 cooler 9 and the feed opening of the heat exchanger 10, and the C1 cooler 9 A third cooling pipe is arranged between the feed inlet and the cold air outlet of the heat exchanger 10, a C2 cooler 8 is arranged on the upper side of the C1 cooler 9, and a pipe is arranged between the outlet of the C2 cooler 8 and the third cooling pipe , a second cooling pipe is set between the air outlet of the C1 cooler 9 and the air inlet of the C2 cooler 8, the roasting furnace 5 is set above the C2 ...

Embodiment 3

[0028] The proportions of the vanadium slag, stone coal and limestone are: 60-70%, 13-15%, 15-25%, and the calcination temperature is 900-1100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com