Food processing, slitting and packaging integrated equipment and method

A food processing and equipment technology, applied in the field of food processing, cutting and packaging integrated equipment, can solve the problems of food contamination, easy adhesion, and easy breeding of bacteria, and achieves the effect of avoiding food contamination and having a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

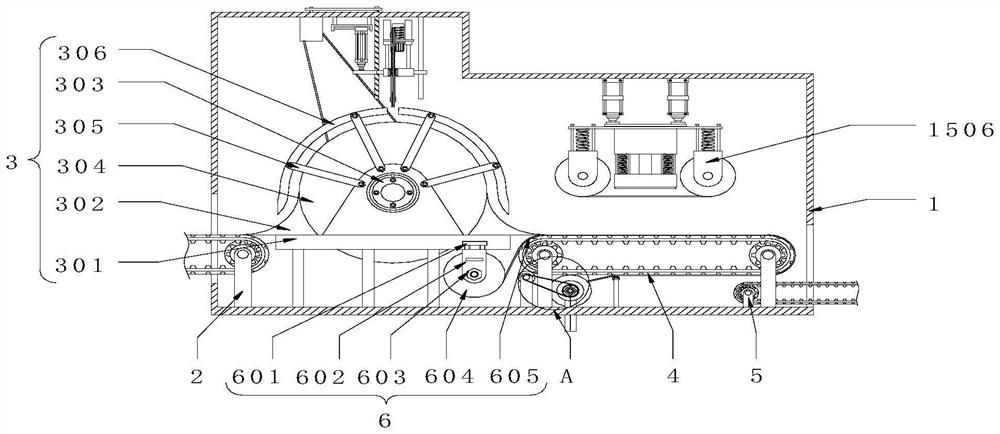

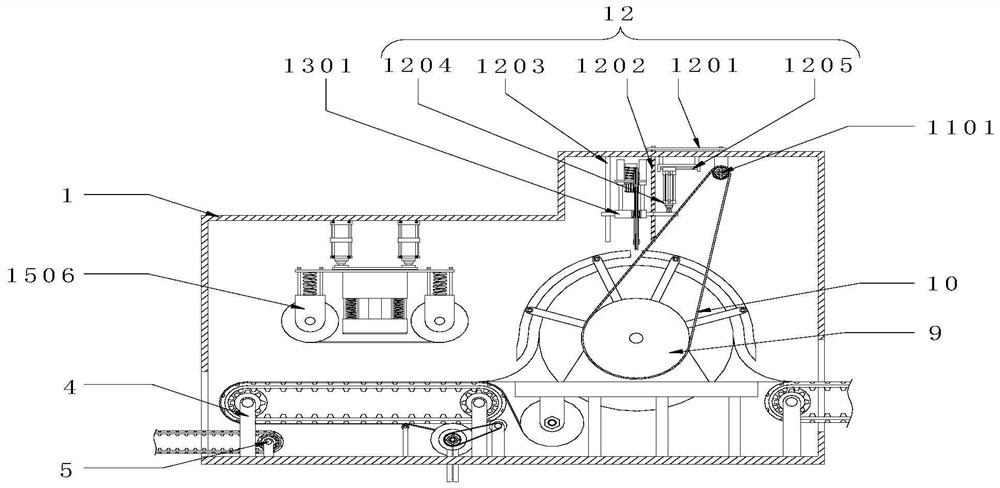

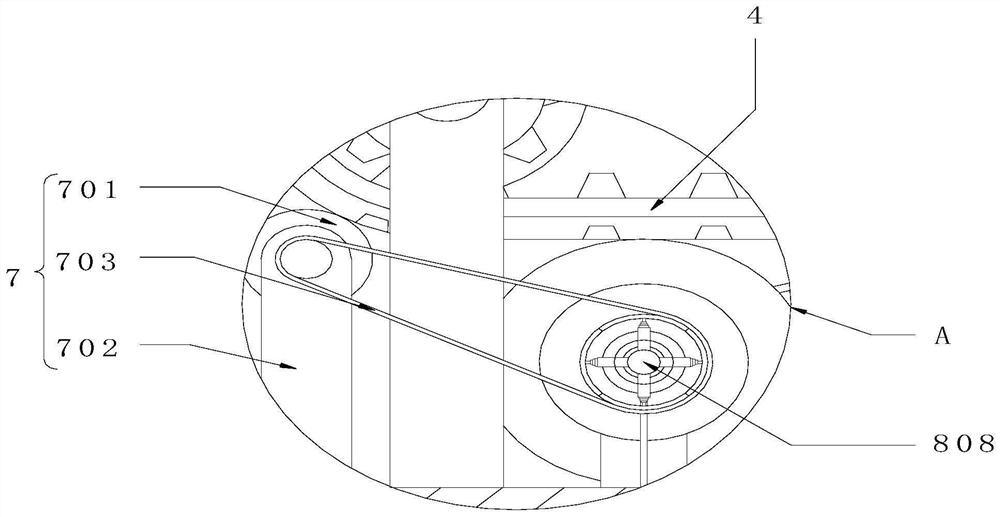

[0033] like figure 2 , Figure 7 and Figure 8 As shown, the present invention provides a technical solution: an integrated equipment for food processing, cutting and packaging, comprising an outer frame 1 and a cleaning assembly 14, the inner upper wall of the outer frame 1 is sequentially provided with a control assembly 12 from left to right and the upper packaging assembly 15, and the control assembly 12 includes a third elastic band 1201, a threaded rod 1202, a guide rod 1203, a single-section air cylinder 1204 and an electric slide rail 1205, the right end of the third elastic band 1201 is connected with a threaded rod 1202, And the outside of the threaded rod 1202 is connected to the wire cutting assembly 13, the right end of the wire cutting assembly 13 is connected with a guide rod 1203, and the upper right end of the wire cutting assembly 13 is installed with a single-section air cylinder 1204, and the upper end of the single-section air cylinder 1204 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com