Energy-saving buffer device for new energy automobile

A technology of new energy vehicles and buffer devices, applied in electric vehicles, power management, vehicle components, etc., can solve problems such as large inertia, spindle wear, energy waste of vehicle sliding, etc., to reduce resonance, avoid wear, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

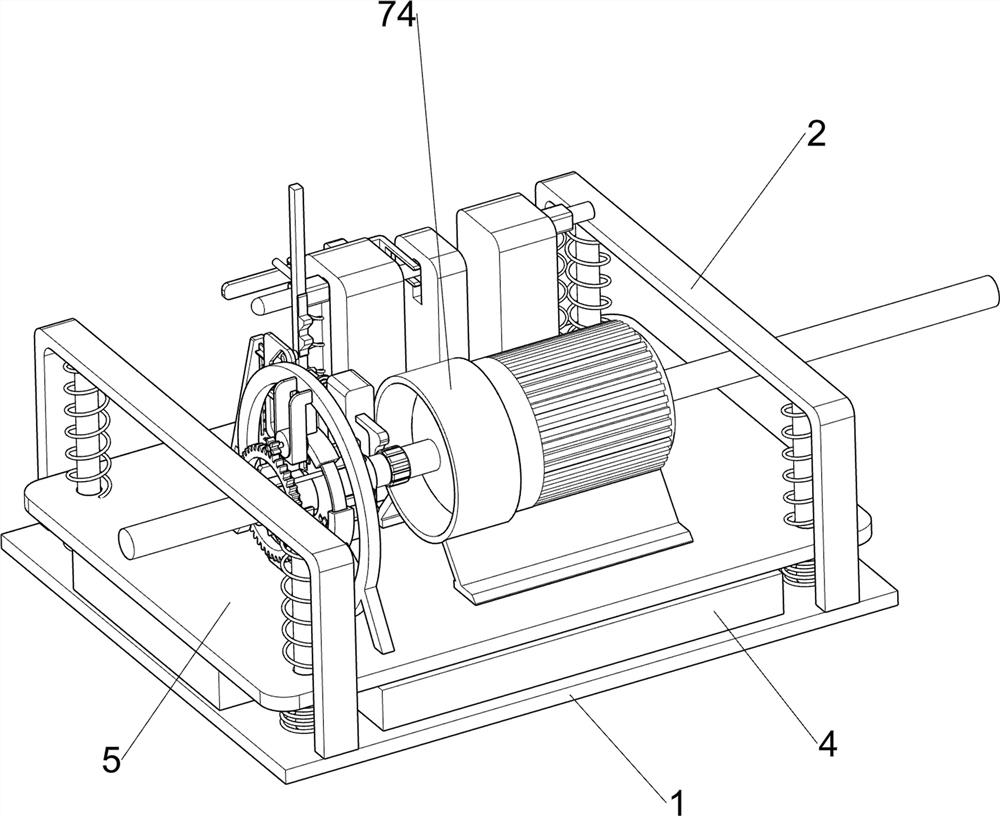

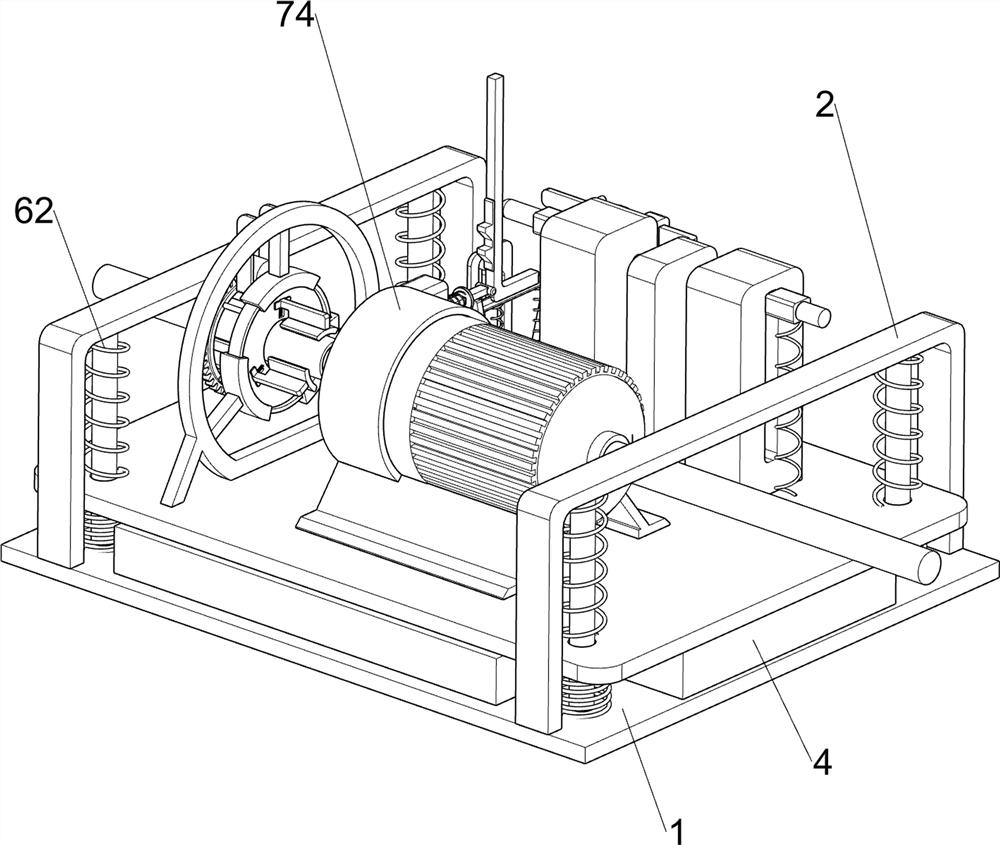

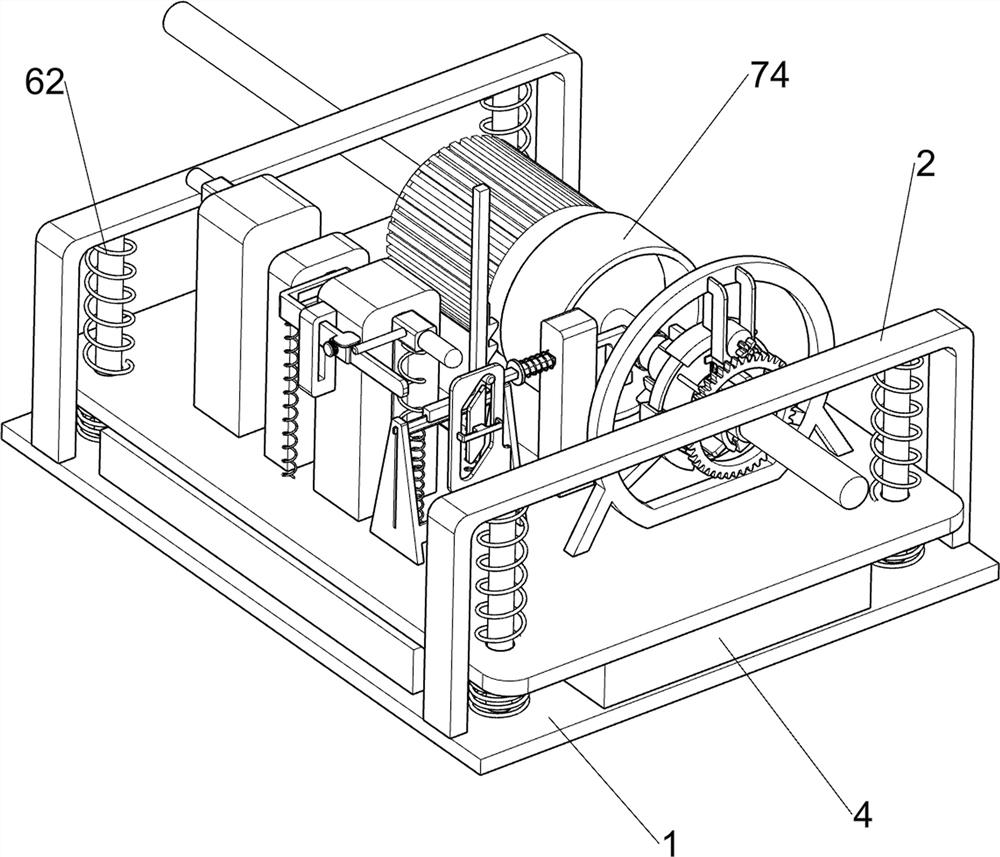

An energy-saving buffer device for new energy vehicles, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, it includes a base plate 1, a U-shaped frame 2, a fixed guide rod 3, a shock pad 4, a mounting groove plate 5, a resonance mitigation component 6, an energy recovery component 7, an electromagnet control component 8 and a lock buffer component 9, A U-shaped frame 2 is symmetrically fixed on the top of the bottom plate 1, and a pair of fixed guide rods 3 are fixed together between the U-shaped frame 2 and the bottom plate 1. A shock-absorbing pad 4 is placed on the top of the bottom plate 1, and the shock-absorbing pad 4 is used for shock absorption and buffering. , the four fixed guide rods 3 are jointly slidably connected with an installation groove plate 5, the installation groove plate 5 is located above the shock-absorbing pad 4, and a resonance mitigation component...

Embodiment 2

On the basis of Example 1, as Figure 12 and Figure 13 As shown, the spot brake buffer assembly 10 is also included. The spot brake buffer assembly 10 is arranged on the installation groove plate 5. The spot brake buffer assembly 10 is used to reduce the inertia of the forward tilt of the vehicle during braking. The spot brake buffer assembly 10 includes a fixed groove. Block 101, point brake lever 102, compression spring 103, triangular fixed plate 104, fixed guide groove plate 105, lift slide plate 106, support spring 107, L-shaped rod 108 and dial block 109, the top of the installation groove plate 5 is fixed with a fixed Slot block 101, the upper part of the fixed slot block 101 is slidably connected to the spot brake lever 102, the spot brake lever 102 is used for spot brake, and a compression spring 103 is connected between the spot brake lever 102 and the fixed slot block 101, and the top of the slot plate 5 is installed to be fixed. A triangular fixing plate 104 is co...

Embodiment 3

On the basis of Example 2, as Figure 14 As shown, it also includes a fixed groove ring 11, the main shaft 75 is provided with a fixed groove ring 11, the fixed groove ring 11 is used to reduce the wear of the main shaft 75 when the brake is applied, and the fixed groove ring 11 is located on the right side of the electromagnetic ring 811.

[0046] During the spot braking process, the grooved ring 11 is fixed, and grooves are formed on the fixing groove ring 11 to increase the friction force during spot braking, which is convenient for spot braking, and at the same time can reduce the wear of the main shaft 75 during spot braking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com