Waste material taking-out mechanical arm of back-end punching machine of injection molding machine

A stamping machine and injection molding machine technology, applied in the field of manipulators, can solve the problems of not being suitable for multi-tasking requirements, and the single function of the automatic retrieving manipulator, so as to achieve the effects of reducing invalid waiting time, limited range of motion, and reducing the injection molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

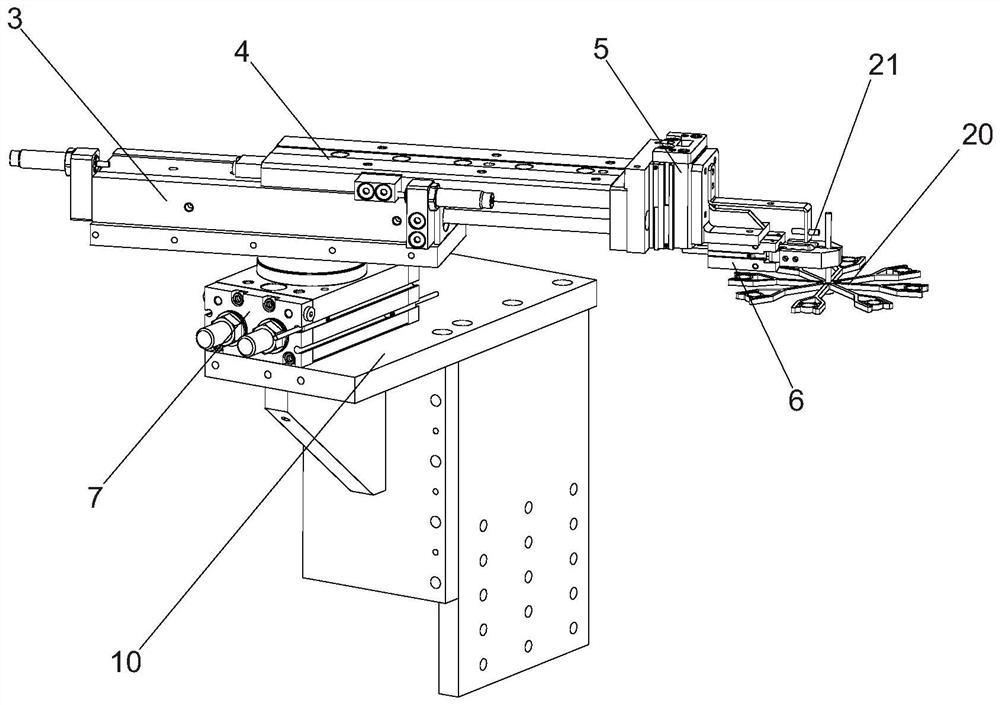

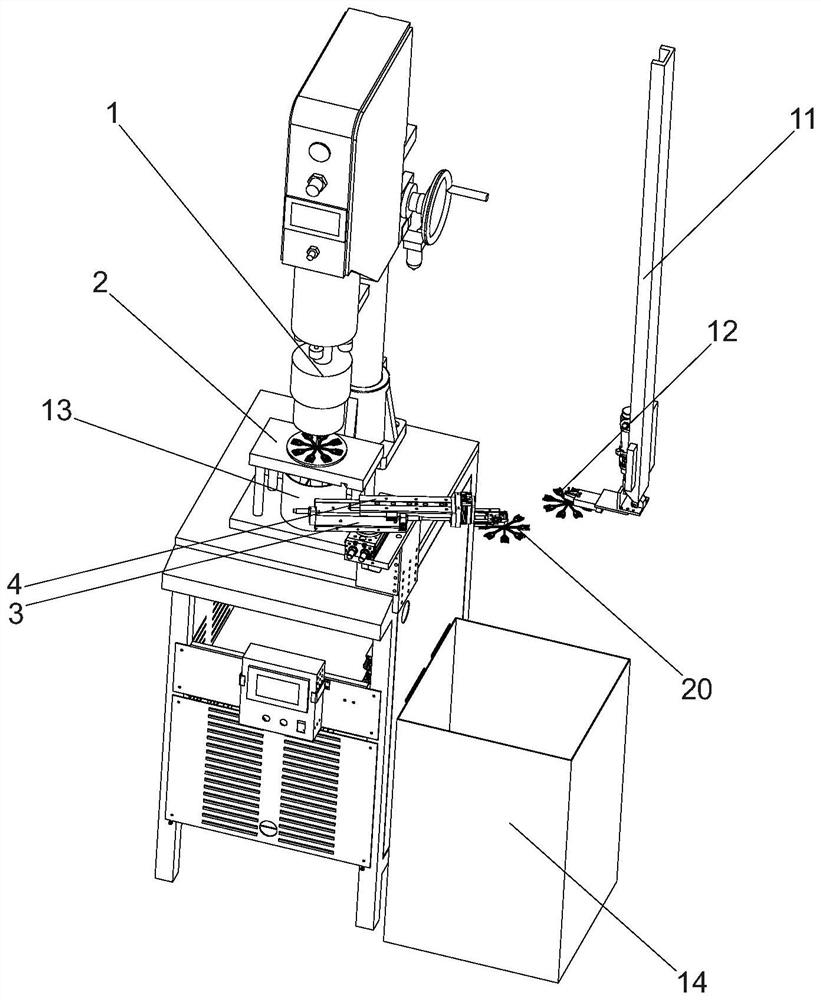

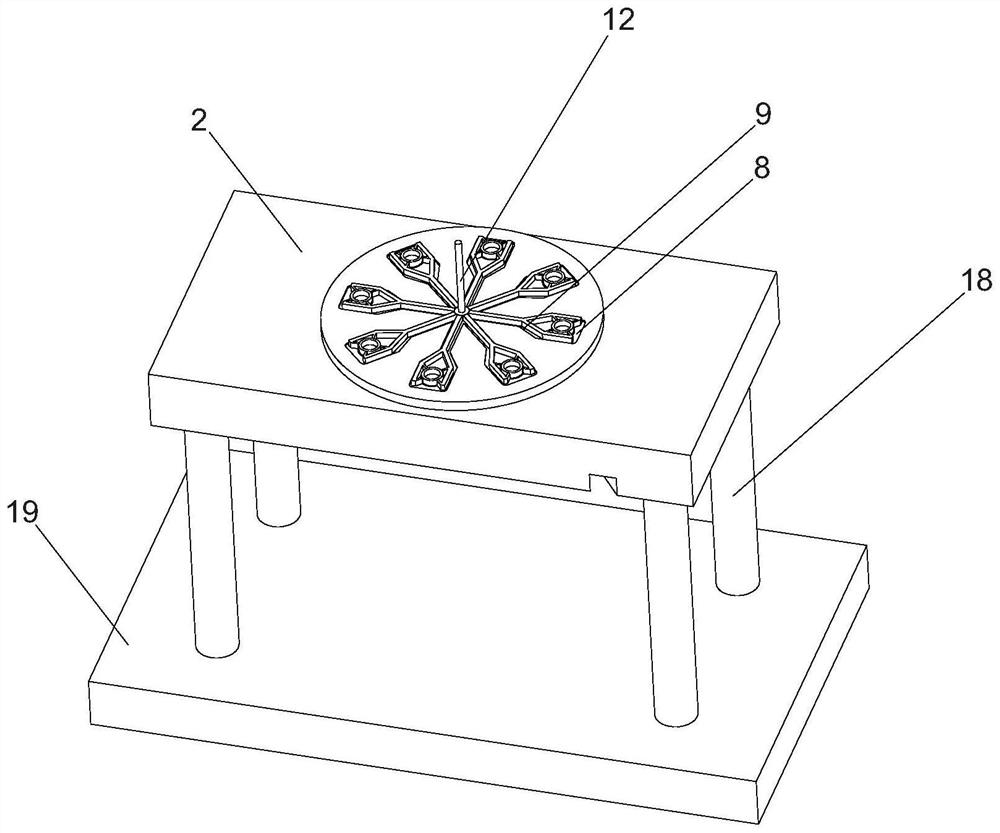

like Figure 1 to Figure 3 As shown, a waste removal manipulator of a punching machine at the back end of an injection molding machine is arranged next to a punching jig 2 of the punching machine, and the punching jig 2 is located directly under the punch 1 of the punching machine, and passes through four jigs. The support rod 18 is overhead fixed on the jig supporting base plate 19, and the jig supporting base plate 19 is fixed on the working table surface of the punching machine through bolts. A material receiving box 13 is placed on the top surface of the jig supporting bottom plate 19 , and the material receiving box 13 is located directly below the punching fixture 2 and is used for receiving the blanking material produced by the punch 1 punching. The punching machine is located downstream of an injection molding machine, and an injection molding machine reclaimer 11 is arranged between the punching machine and the injection molding machine. The product 12 is in the shape...

Embodiment 2

Embodiment 3

There are two stamping jigs 2, all of which are located on a jig rotation turntable. The jig rotation turntable includes a rotary arm 15, a lifting table 16 and a transposition motor 17. The output end of the transposition motor 17 is connected to the center key of the rotary arm 15. connected, the two punching fixtures 2 are respectively fixed on both ends of the rotating arm 15 . The lifting table 16 includes a jib lifting cylinder and a supporting plate. The jib lifting cylinder is fixed on the working surface of the punching machine, the supporting plate is fixed on the piston rod of the jib lifting cylinder, and two jib lifting cylinders are slidably connected to the jib lifting cylinder. The guide rod is parallel to the piston rod of the jib lift cylinder and connected to the bottom of the pallet. A motor suspension 22 is fixed on the top of the support plate, and the transposition motor 17 is fixed under the top plate of the motor suspension 22 . The transposition motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com