Automatic steel belt coiling and packing device

An automatic coiling and steel strip technology, applied in transportation and packaging, thin material handling, climate sustainability, etc., can solve the problems of low coiling efficiency, low degree of automation, poor operation safety, etc., and save manpower , Improve the degree of automation and improve the effect of coiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below the attachment in the embodiments of the invention will be clearly and fully described in the technical solutions in the embodiments of the present invention. Obviously, the embodiments described are only a part of the embodiments of the invention, not all embodiments.

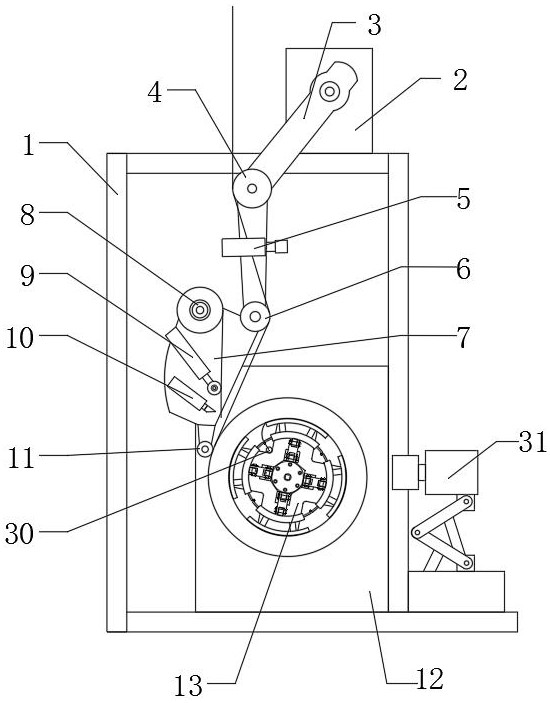

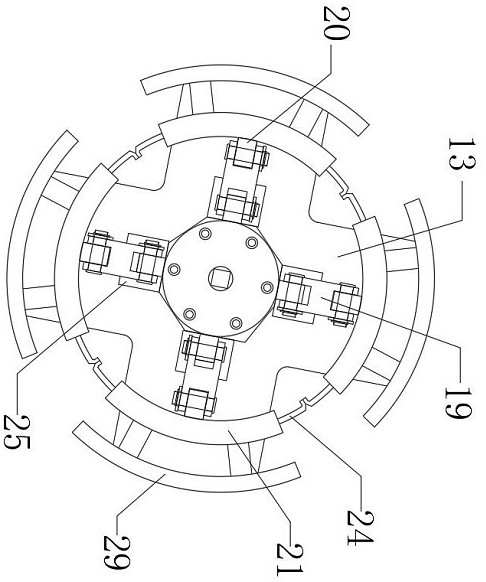

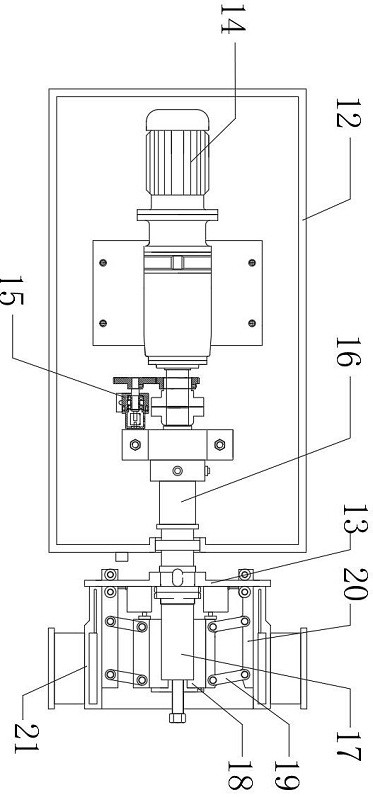

[0024] Reference Figure 1-4 , A kind of automatic roll -up packaging device, including the roll rack 1. Swing arm 3. Patch tape mechanism installed on the free end of the swing arm, the roll head, and the hydraulic connection holding mechanism installed on the roll head;

Fixed the swing arm drive motor 2 on the closing rack 1, and the output shaft of the swing arm drive motor 2 is fixed to one end of the swing arm 3, which is swinged by the swing arm drive motor 2 driver. Install the first -class steel band -oriented wheel in order to be installed in sequence. The first -level steel band -oriented wheel 4, the second -level steel band guide wheel 6 and the steel belt pressure roller 11 are rotated an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com