A kind of counterweight type blanking buffer device for extruder and counterweight control system

The technology of a buffer device and an extruder is applied in the field of extruder blanking, which can solve the problems of easily smashing the remaining material transportation line, damage, insufficient deceleration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

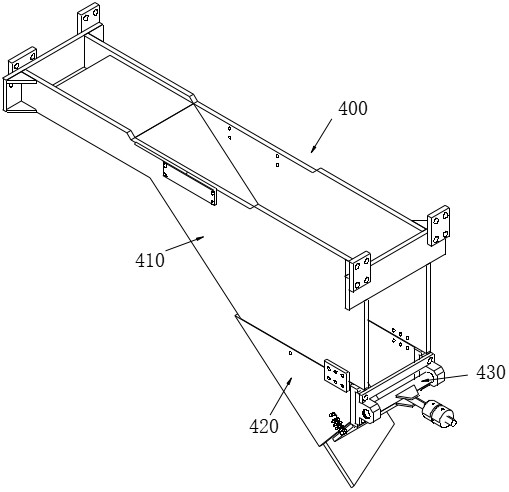

[0055] For the second embodiment, see Figure 4 As shown, this embodiment discloses a first guide assembly 410. The first guide assembly 410 includes a first side plate 411 and a first guide plate 412. There are two first side plates 411, which are respectively connected to the first guide plate. On both sides of the 412, a short blanking channel is enclosed by the two first side plates 411 and the first guide plate 412. On this basis, a second guide assembly 420 is disclosed. The second guide assembly 420 includes a second guide plate 422. , the two sides of the second guide plate 422 are provided with second side plates 421, the two second side plates 421 and the second guide plate 422 enclose an extended blanking channel, and the second guide plate 422 and the first guide plate 412 The connecting components 440 are used for connection and fixation, and the short blanking channel formed by the first guide plate 412 is extended by extending the blanking channel, so as to redu...

no. 3 example

[0058] The third embodiment, this embodiment discloses another connection method of the first guide plate 412 and the second guide plate 422 on the basis of the second embodiment, please refer to Figure 7 As shown, the second guide plate 422 is connected to the bottom of the first guide plate 412, and a cliff 422B is formed at the position where the first guide plate 412 and the top surface of the second guide plate 422 are connected, because the first guide plate 412 has a certain thickness , with respect to the residual material, the first guide plate 412 having a thickness when moved to the connecting position will form a cliff-like structure (ie, the cliff step 422B) at the second guide plate 422, and the residual material at the cliff step 422B The second guide plate 422 will be impacted (the thickness of the first guide plate 412 is only 2-3cm, and the impact force will not cause damage to the second guide plate 422), and the impact of the second guide plate 422 will hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com