Metal adsorption fiber membrane and preparation and application thereof

A technology for adsorbing fibers and metals, which is applied in the field of fiber membrane materials, can solve the problems of difficult adsorption performance and structural stability, and achieve excellent chelation effect, good metal ion capture ability and selectivity, and unique selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] (1) Preparation of PAN solution

[0075] The PAN solution is prepared by uniformly mixing polyacrylonitrile with a molecular weight of 150,000 and solvent N,N-dimethylacetamide according to weight percentages of 12wt% and 88wt% at 60°C.

[0076] (2) Preparation of PVDF solution

[0077] The PVDF solution is prepared by mixing 12wt% and 88wt% of PVDF with a model of 6020 and a solvent N,N-dimethylacetamide at normal temperature.

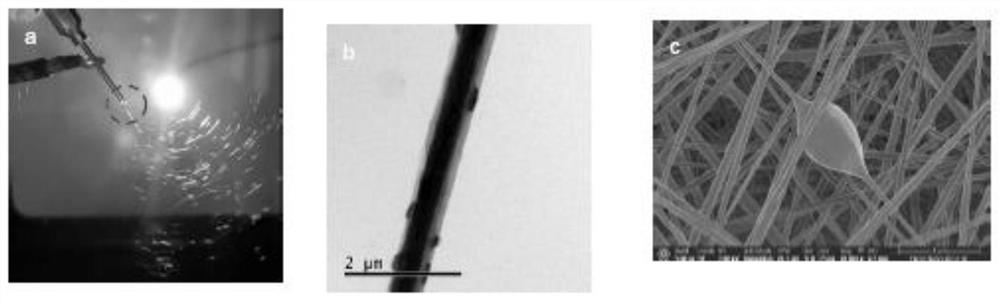

[0078] (3) Preparation of base film

[0079] The film casting liquid obtained in step (1) (2) was loaded into a 10mL syringe respectively, and a coaxial needle was connected with a Teflon catheter. The flow rate of the casting liquid was 0.5 mL / h, the winding speed of the drum was 300 rn / min, and the base film was obtained for 2 hours.

[0080] (4) Preparation of composite nanofiber membrane

[0081] With the base film of step (3) gained and the mixed solution of 100mL hydroxylamine hydrochloride and anhydrous sodium carbonate (wherein, the...

Embodiment 2

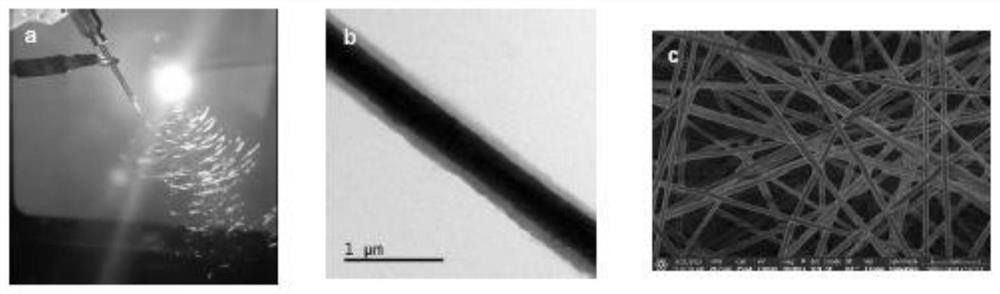

[0086] Compared with Example 1, the main difference is that the voltage of the spinning process is adjusted:

[0087] (1) Preparation of PAN solution

[0088] The PAN solution is prepared by uniformly mixing polyacrylonitrile with a molecular weight of 150,000 and solvent N,N-dimethylacetamide according to weight percentages of 12wt% and 88wt% at 60°C.

[0089] (2) Preparation of PVDF solution

[0090] The PVDF solution is prepared by mixing 12wt% and 88wt% of PVDF with a model of 6020 and a solvent N,N-dimethylacetamide at normal temperature.

[0091] (3) Preparation of base film

[0092]The film casting liquid obtained in step (1) (2) was put into a 10mL syringe respectively, and a coaxial needle was connected with a Teflon catheter. The flow rate of the casting liquid was 0.5 mL / h, the winding speed of the drum was 300 rn / min, and the base film was obtained for 2 hours.

[0093] (4) Preparation of composite nanofiber membrane (same as Example 1)

[0094] The base film ...

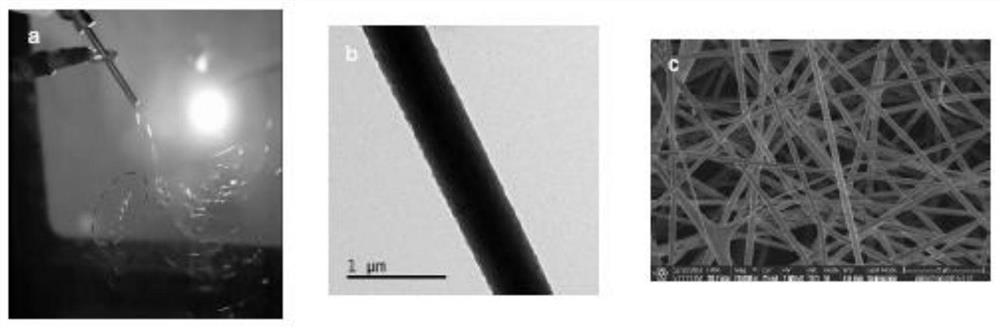

Embodiment 3

[0099] Compared with Example 1, the main difference is that the voltage of the spinning process is adjusted:

[0100] (1) Preparation of PAN solution

[0101] The PAN solution is prepared by uniformly mixing polyacrylonitrile with a molecular weight of 150,000 and solvent N,N-dimethylacetamide according to weight percentages of 12wt% and 88wt% at 60°C.

[0102] (2) Preparation of PVDF solution

[0103] The PVDF solution is prepared by mixing 12wt% and 88wt% of PVDF with a model of 6020 and a solvent N,N-dimethylacetamide at normal temperature.

[0104] (3) Preparation of base film

[0105] The film casting liquid obtained in steps (1) and (2) was respectively put into a 10mL syringe, the coaxial needle was connected with a Teflon catheter, the distance between the needle and the roller was adjusted to 15cm, and a 15kv high-voltage static electricity was connected to the needle , the flow rate of the casting liquid is 0.5mL / h, the winding speed of the drum is 300rn / min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com