Spiral grating groove loaded circular waveguide TM01-TE01 mode converter

A mode converter and circular waveguide technology, applied in waveguide devices, circuits, electrical components, etc., can solve the problems of large mode converter size, increased difficulty in process realization, complex structure, etc., and achieve high polarization conversion efficiency, The effect of small size and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

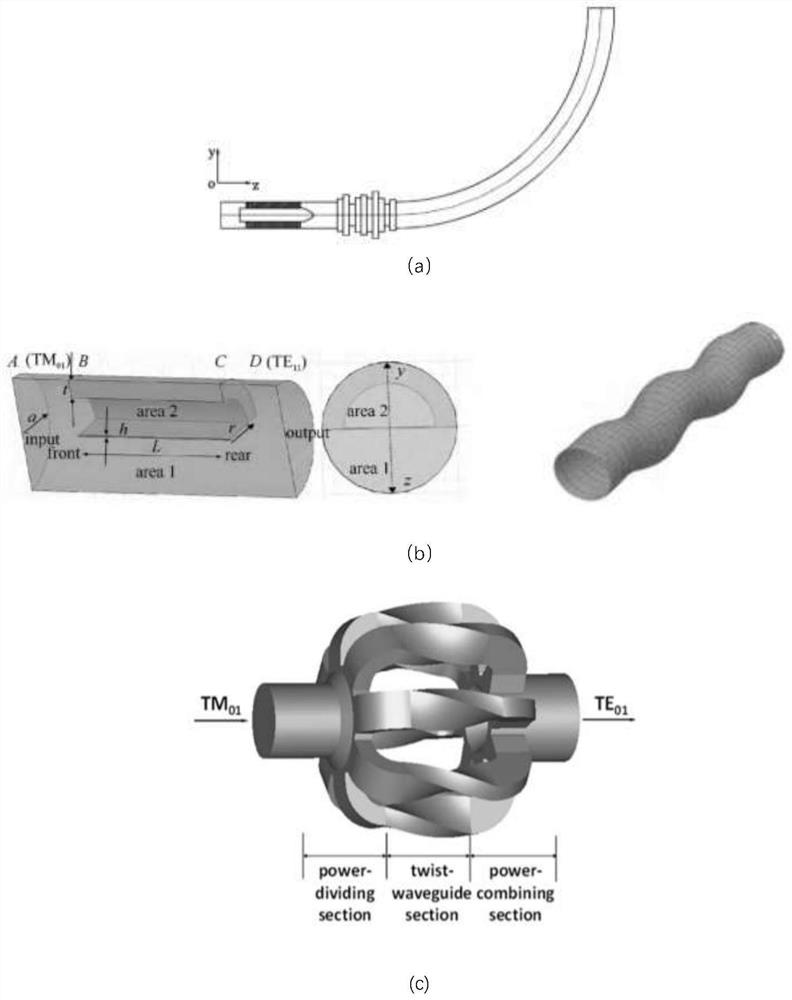

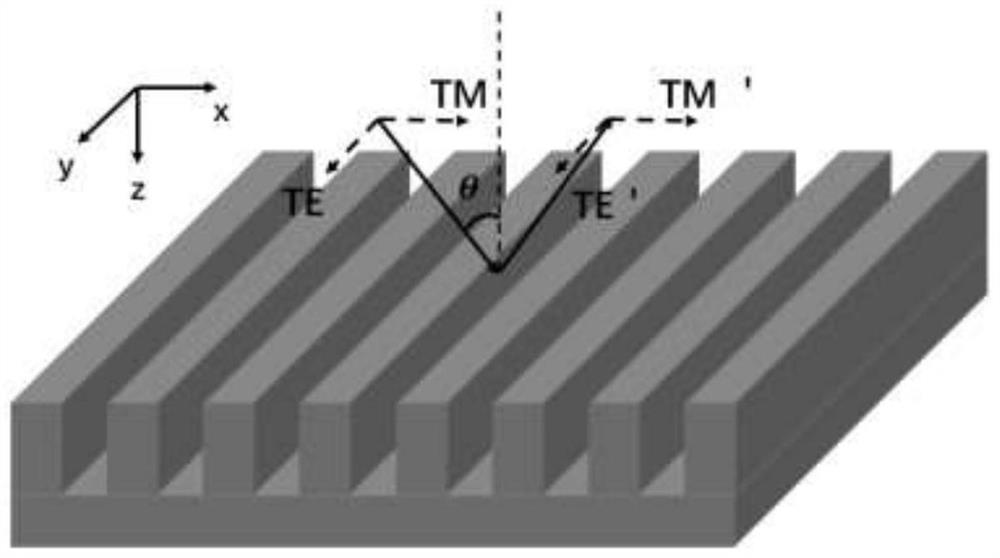

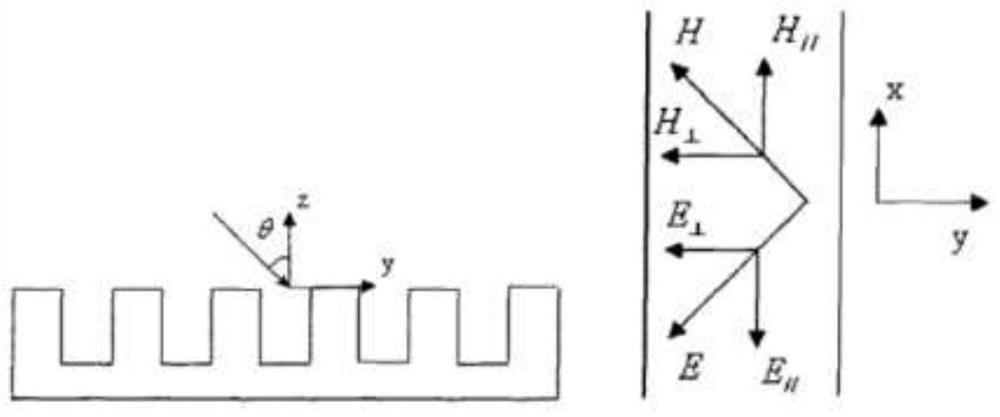

[0030] Circular waveguideTM loaded with spiral grating grooves centered at 12GHz 01 -TE 01 Mode converters for example, such as Figure 5 As shown, the mode converter includes a coaxial and sequentially connected input circular waveguide, an input transition section, a mode conversion section, an output transition section, and an output circular waveguide; the input transition section and the output transition section are horn shapes with a linear gradient in radius; the mode The transformation section is a circular waveguide with equidistant spiral grating grooves on the inner wall, and the equidistant spiral grating grooves are composed of several spiral grooves arranged periodically; the circular waveguideTM 01 The beam is fed from the input circular waveguide, and finally output from the output circular waveguide to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com