Online detection method for granulation effect of cylinder mixer

A cylinder mixing and detection method technology, which is applied in the direction of measuring device, particle size analysis, particle and sedimentation analysis, etc., can solve the problem that the granulation effect of the mixer cannot be measured and described, local loose materials or large sticky materials appear, and the process is difficult to be accurate Control and other issues, to achieve the effect of online real-time particle size detection, simple and reliable algorithm, and fast analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Now take the secondary cylinder mixing production process in domestic typical sintering production as an example to illustrate the present invention:

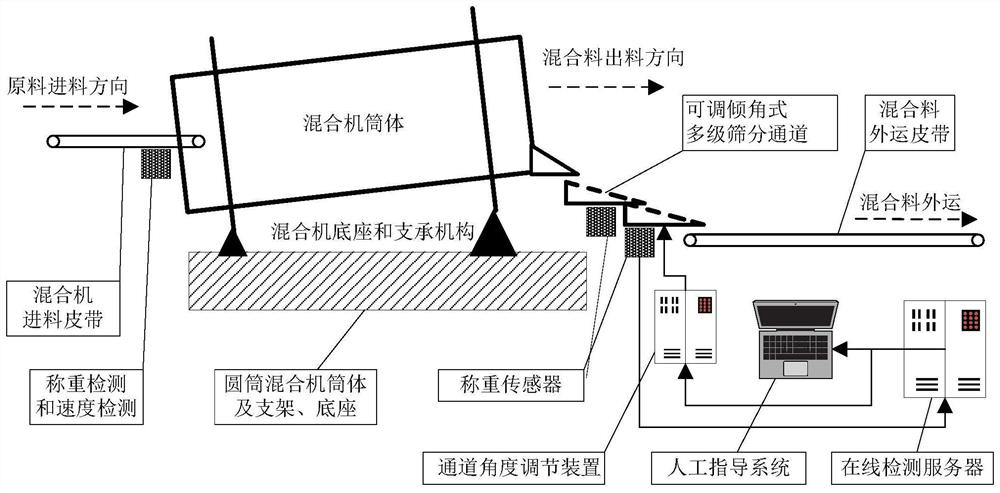

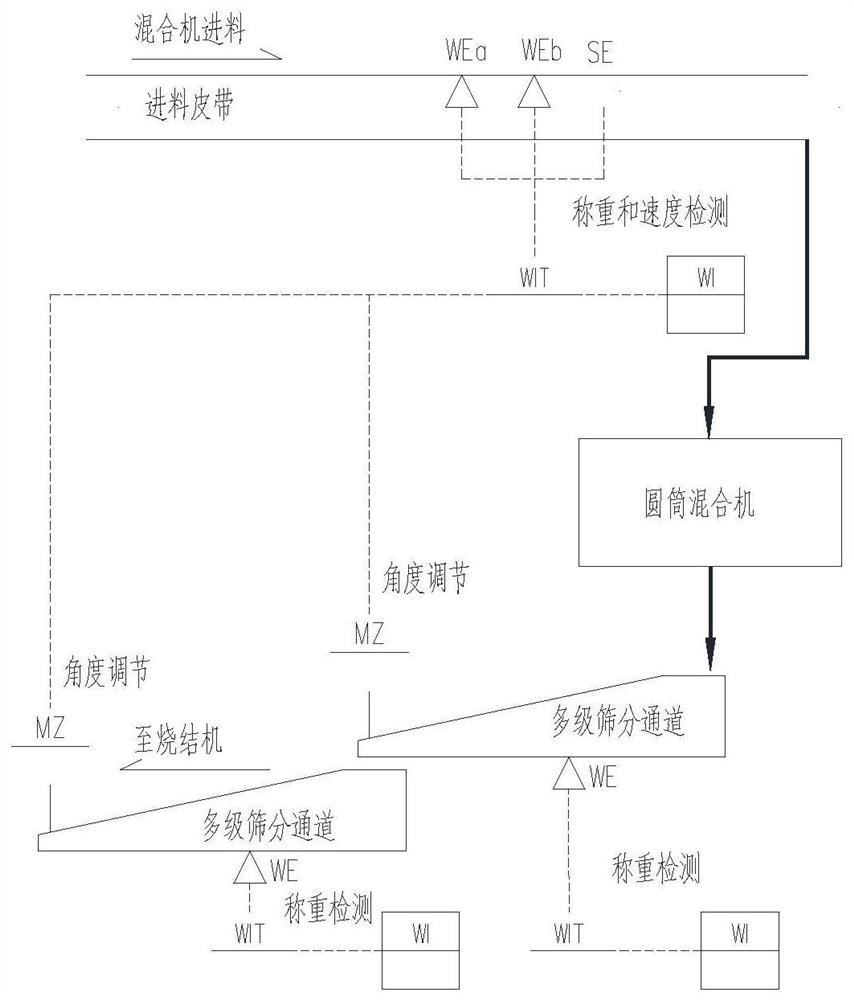

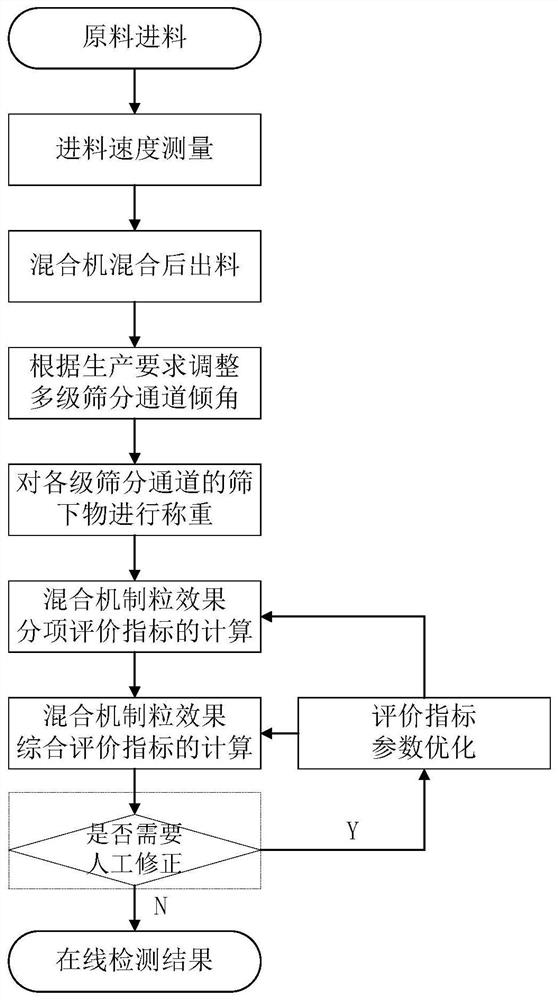

[0055] The invention provides an online detection method for the granulation effect of a cylinder mixer, and the content of the method is described as follows. A weighing detection and belt speed detection device is installed on the belt at the feed inlet of the cylinder mixer to measure the feed speed of the mixer. An adjustable inclination multi-stage screening channel is set at the discharge port of the cylinder mixer. After mixing, the material will first fall on the falling surface of the screening channel, and the sieve holes of the screening channel gradually change from small to large. The mixed material is separated step by step according to the particle size, and the bulk material under the sieve slides down to the mixed material delivery belt through the channel under the sieve. By adjusting the inclination a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com