Auxiliary net belt net feeding device and net feeding method for macromolecule filter net setting machine

A setting machine and polymer technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as affecting production efficiency, large labor costs, affecting filter quality, etc., to improve Internet access efficiency and save labor costs. Effect

Pending Publication Date: 2022-05-31

礼德滤材科技(苏州)有限责任公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Before the polymer filter screen is finalized, the wound filter screen roll needs to be unwound by manpower. Generally, the filter screen with a width of more than 3 meters needs 3-7 people to cooperate to unwind and pass through the heating roller and drafting roller successively. Bottom, and as the unwinding length of the filter screen increases, in order to avoid direct friction between the filter screen and the ground to damage the screen surface, the filter cloth that workers need to pull will be heavier (the total weight of the filter screen is about 1-2.5t), and the labor cost is relatively large

In the traditional netting process, the worker needs to manually lift the two ends of the fully expanded filter screen and climb over the drafting roller and heating roller respectively, so that the two ends of the filter screen fall between the drafting roller and the heating roller , the top of the drafting roller and the heating roller are usually above 1.5 meters in height, and it is extremely inconvenient for workers to lift it up by manpower; On the stretching roller, during the splicing process, workers need to stand on the mesh surface to operate, and it is inevitable to step on some mesh surfaces, causing damage to the mesh surface structure, and there is a hidden danger of affecting the quality of the filter mesh

In addition, the existing mesh belt manual loading method usually takes more than 1 hour, which seriously affects the production efficiency while occupying the setting machine time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

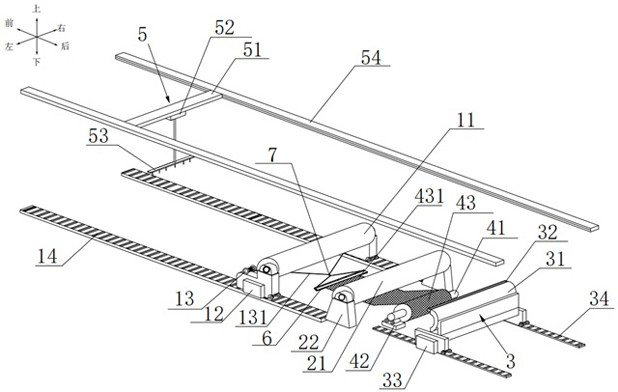

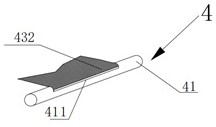

The invention discloses a net belt auxiliary net feeding device and a net feeding method of a polymer filter net setting machine. The net belt auxiliary net feeding device comprises a lower conveying mechanism and an upper conveying mechanism, the lower conveying mechanism is used for enabling a filter screen on a filter screen roller located between a heating roller and a back cover to sequentially penetrate through the lower portion of the heating roller and the lower portion of a traction roller in the horizontal direction so as to be away from the filter screen roller. The upper conveying mechanism is used for lifting the filter screen penetrating through the traction roller to the position above the traction roller from the position below the traction roller, sequentially crosses the traction roller, the heating roller and the position above the filter screen roller in the horizontal direction and is reversely conveyed to the back cover, and the end of the filter screen is connected at the position of the back cover to form an annular sleeve net. According to the internet surfing method, after the net belt auxiliary internet surfing device completes the downward penetrating and upward crossing processes of the filter net, an annular sleeve net is formed through connection, and the internet surfing process is completed. According to the auxiliary net belt internet surfing device, the internet surfing efficiency is improved, and the labor cost is greatly saved; and the hidden danger that the quality of the filter screen is influenced due to treading in the traditional filter screen jointing process is solved.

Description

A mesh belt auxiliary Internet access device and Internet access method of a polymer filter screen setting machine technical field The present invention relates to finished product filter screen processing equipment technical field, specifically a kind of net of polymer filter screen shaping machine With auxiliary Internet access device and Internet access method. Background technique [0002] The polymer filter screen must be heat-set after being formed into a network to eliminate the internal stress, improve the crystallinity of its polymer materials, and optimize the material properties. Usually the setting equipment consists of a drafting roller and a heating roller. The filter screen needs to be formed into a net ring and set on two rollers for heating and tension stretching. Before the polymer filter is shaped, it needs to be wound The screen roll is unwound by manpower. Usually, the screen with a width of more than 3 meters needs 3-7 people to cooperate to unf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06C7/02B01D39/14

CPCD06C7/02B01D39/14B01D2239/10Y02W30/62

Inventor 王洋

Owner 礼德滤材科技(苏州)有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com