Production process of color transfer label with stereoscopic impression

A production process and three-dimensional effect technology, applied in the production process of color transfer labels, can solve the problems of high scrap rate and poor storage of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

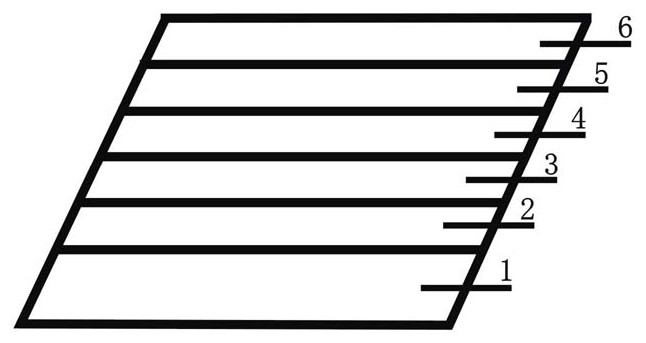

[0014] exist figure 1 Among them, a production process of a three-dimensional color transfer label, using a release material 1 with a certain release force that is pre-coated with silicone oil. The release material 1 can be a release paper or a release film. For color printers (flat or roll paper), first spray special UV glue 2 on the release material 1. During the printing process, the UV glue 2 is irradiated by the UV lamp of the printer and is completely dry; then spray UV white ink 3 on the glue, Now the UV white ink 3 is irradiated by the UV lamp of the printer, and it is completely dry; then the color pattern 4 is sprayed, and the colored ink is irradiated by the UV lamp of the printer in the printing process, and it is completely dried; then the UV varnish 5 is sprayed on the color pattern 4, During the printing process, the UV varnish 5 is irradiated by the UV lamp of the printer, and has been completely dried; the color pattern 4 with a certain thickness is not only b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com