Non-linear model predictive control of process

A model and control device technology, applied in the direction of program control, adaptive control, general control system, etc., can solve problems such as lack of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

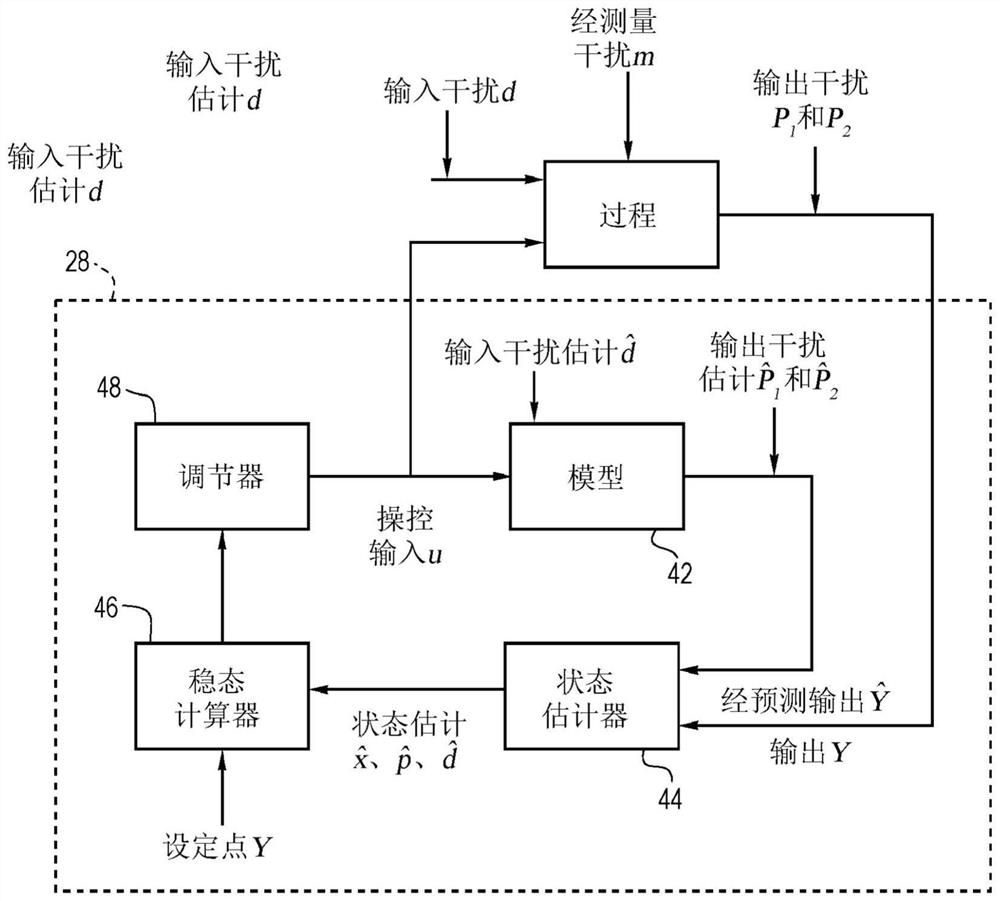

Method used

Image

Examples

example

[0123] A control device for a chemical system implementing a process with steady state gain reversal is applied to maximize the selectivity of the reaction to ethylene oxide (EO). A silver-based catalyst for the selective oxidation of ethylene to ethylene oxide is used to produce ethylene oxide, thereby minimizing secondary reactions that reduce ethylene oxide (EO) selectivity. For conventional catalysts, the EO selectivity does not reach values higher than 85.7%, which has long been regarded as the theoretical maximum selectivity for the following overall reaction:

[0124] 7C 2 H 4 +6O 2 →6C 2 H 4 O+2CO 2 +2H 2 O(33).

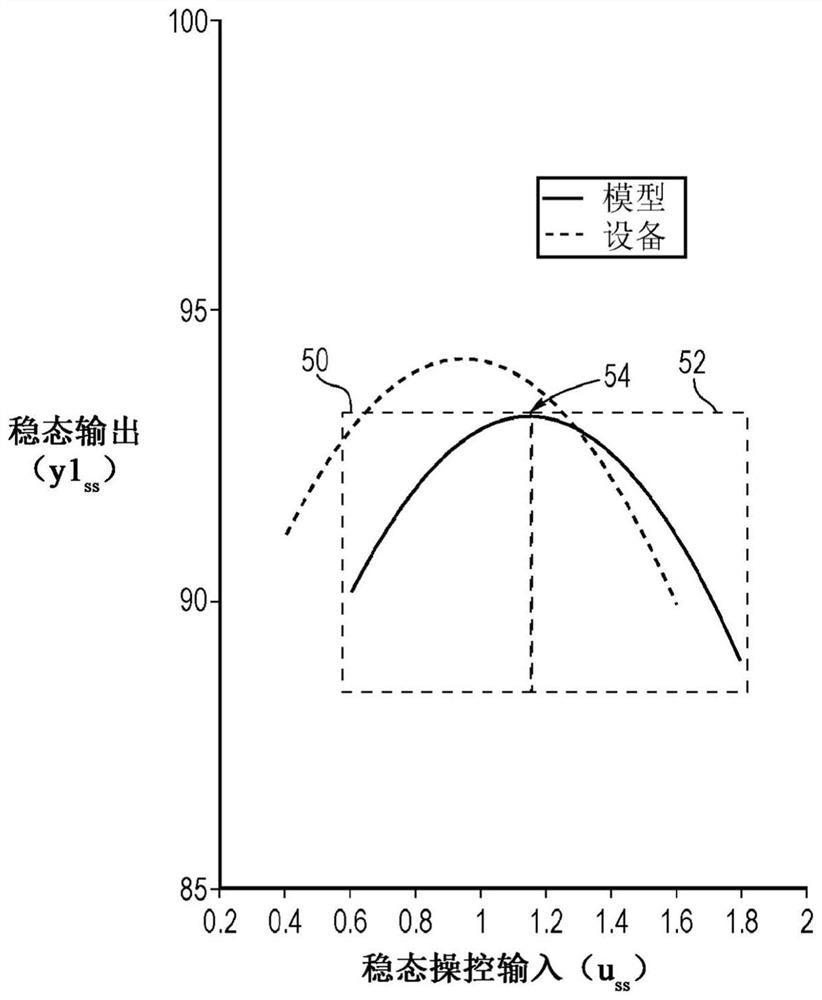

[0125] Some commercial ethylene epoxidation reactors use a co-fed chlorination promoter, which is adsorbed on the catalyst to modify by promoting or moderating certain reaction pathways and in this way increasing the selective oxidation of ethylene oxide. Efficient commercial catalysts tend to exhibit relatively steep parabolic curves for EO selecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com