Method and system for rapidly controlling water content in proton exchange membrane fuel cell

A proton exchange membrane, fuel cell technology, applied in fuel cell control, fuel cells, fuel cell additives, etc., can solve the problems of multiple leads, oscillation, long adjustment time, long AC impedance spectrum test time, etc., to suppress oscillation Amplitude, satisfying fast response, good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

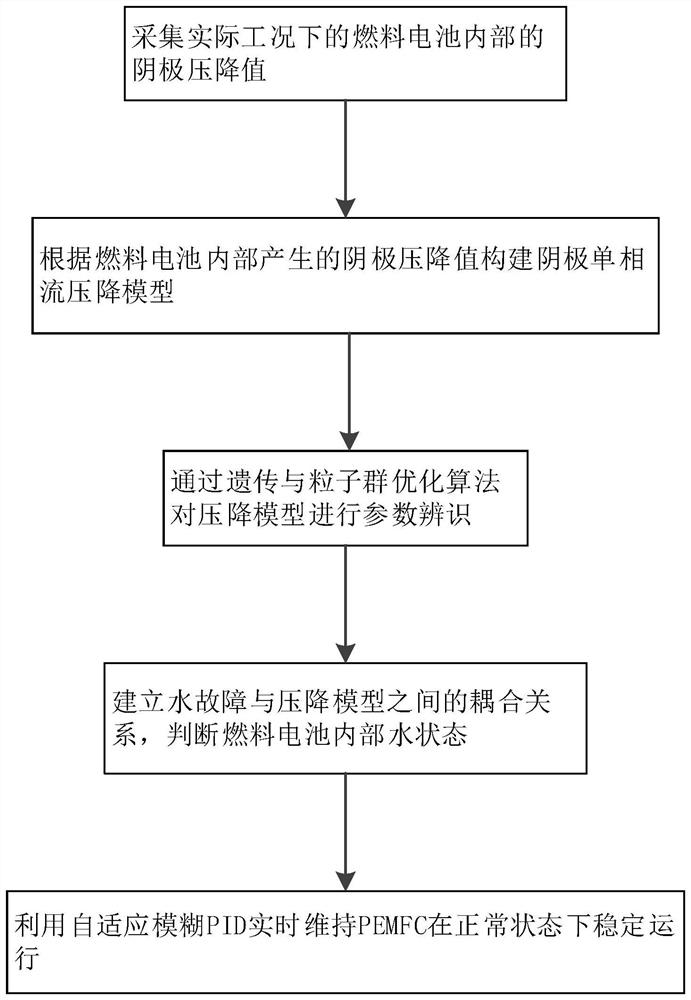

[0050] This embodiment provides a rapid control method for the internal water content of a proton exchange membrane fuel cell, such as figure 1 shown.

[0051] A 156W proton exchange membrane fuel cell (parameters shown in Table 1) is taken as an example for description.

[0052] Table 1

[0053] slices 1 Effective area 275cm 2

Runner parameter L / nAD h 2

4.8×10 10

Flow field parallel channel Plate material Metal rated power 156W@0.6V

[0054] First, the cathode pressure drop value of the proton exchange membrane fuel cell under this condition is collected according to the real-time operating data.

[0055] According to the pressure drop generated inside the PEM fuel cell (along the way resistance, gravity head, hydrogen consumption, etc.), ignoring the acceleration loss caused by the gas consumption and the change of the inlet and outlet flow rates, the pressure loss after the fluid passes through the flow channel...

Embodiment 2

[0073] This embodiment provides a rapid control system for the internal water content of a proton exchange membrane fuel cell, such as Figure 5 shown, it includes:

[0074] Cathode pressure drop value acquisition unit: collects the cathode pressure drop value inside the proton exchange membrane fuel cell under actual working conditions;

[0075] Cathode single-phase flow pressure drop model building unit: build a cathode single-phase flow pressure drop model according to the cathode pressure drop value generated inside the proton exchange membrane fuel cell;

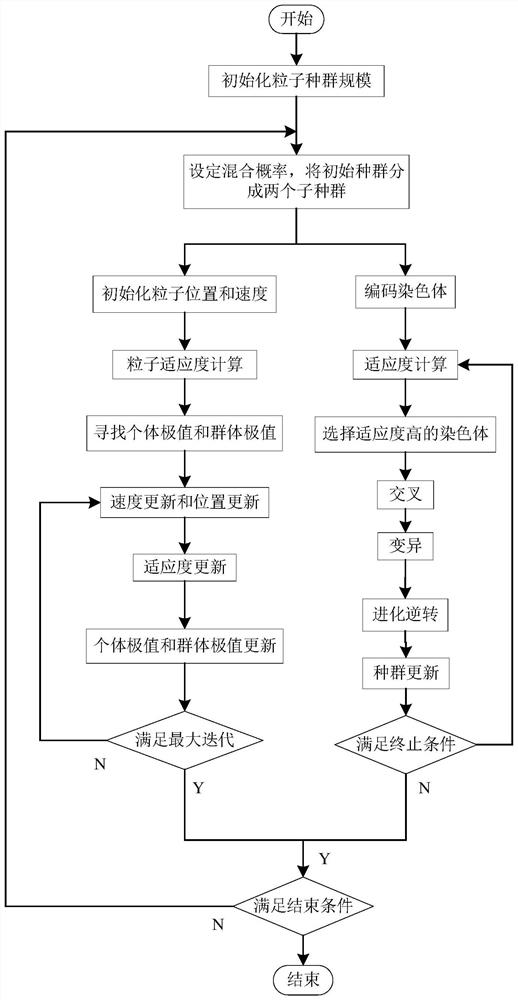

[0076] Parameter identification unit: identify the parameters of the cathode single-phase flow pressure drop model through a hybrid algorithm of genetics and particle swarm optimization;

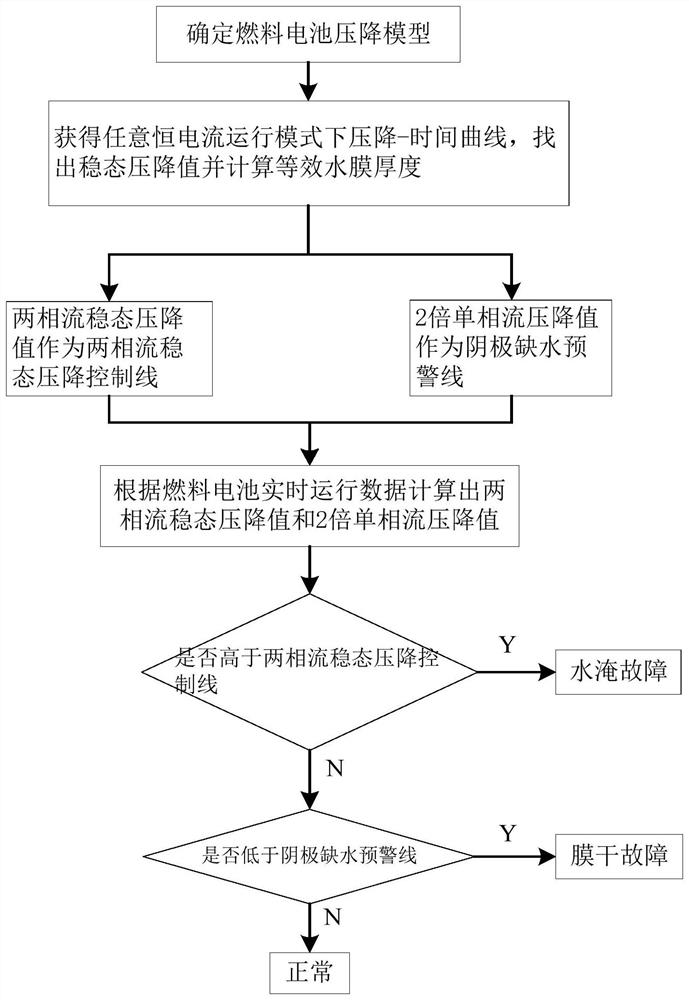

[0077] Internal water state judgment unit: establish the coupling relationship between the water fault and the cathode single-phase flow pressure drop model, and judge the internal water state of the proton exchange membrane fuel cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com