Engine piston remote measurement system reliability detection device and test method

A telemetry system and detection device technology, which is applied in the field of reliability detection devices for engine piston telemetry systems, can solve problems such as long preparation period, impact on test system accuracy, and increased failure of piston telemetry systems, so as to improve detection efficiency, strong versatility, The effect of increasing the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical features, objects and effects of the present invention, specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

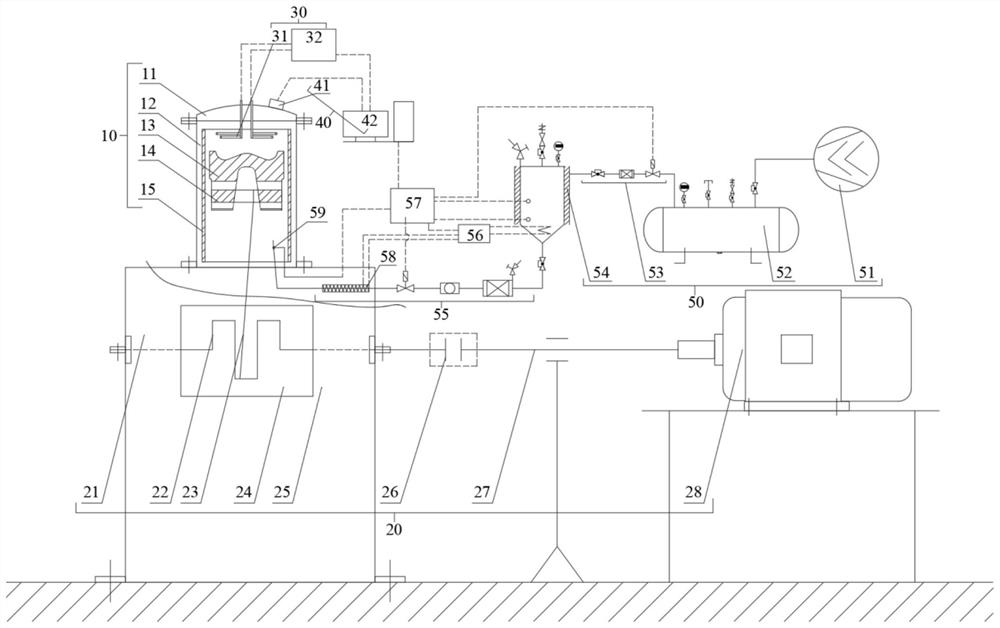

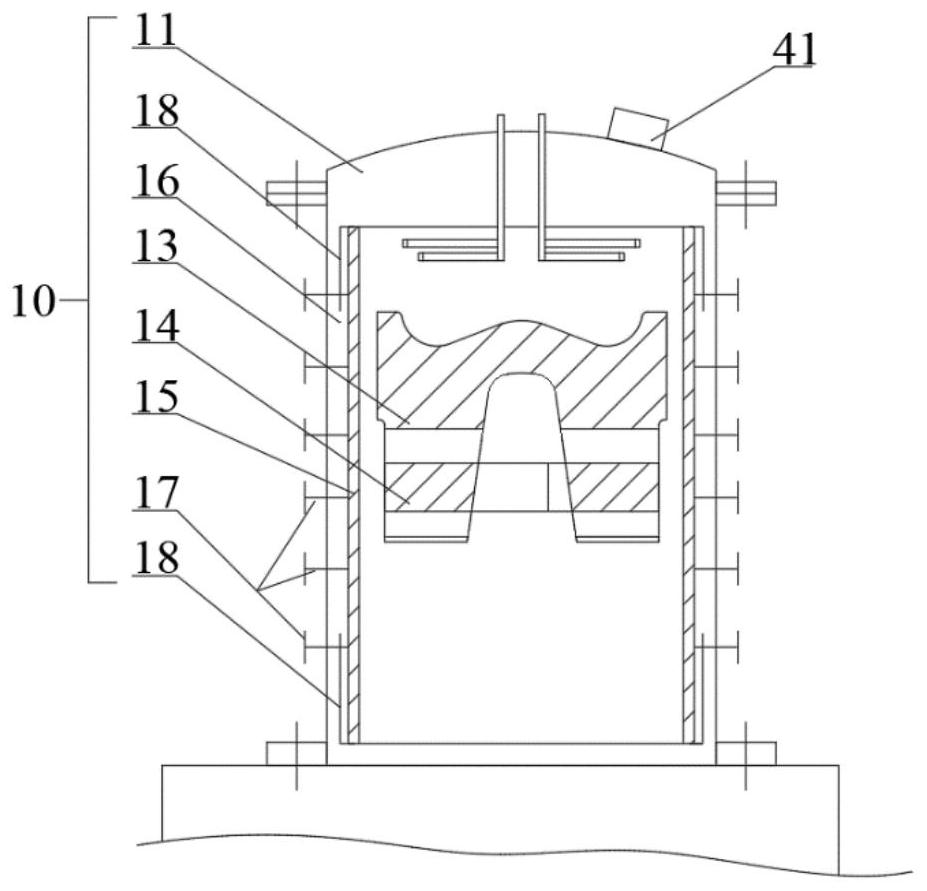

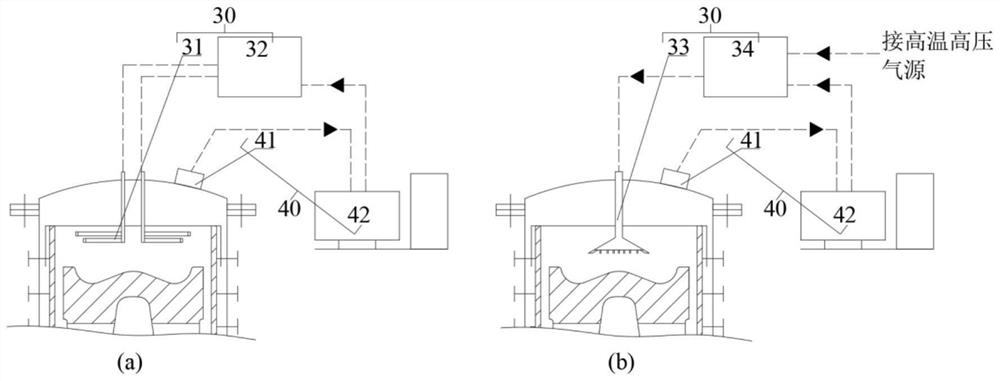

[0046] like figure 1 As shown, it is a schematic structural diagram of a reliability detection device for an engine piston telemetry system according to a preferred embodiment of the present invention, including:

[0047] The detection part 10 includes a cylinder head 11 , a casing 12 , a piston 13 equipped with a telemetry system to be detected, and a cylinder liner 15 . The cylinder head 11 and the casing 12 are connected by bolts, and the casing 12 is connected and fixed to the cylinder block 21 by bolts. The cylinder liner 15 is fixed in the casing 12, the piston 13 is located in the cylinder liner 15 and can reciprocate up and down, and the piston 13 to be tested and the cylinder liner 15 should meet the matching requirements, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com