Taper sleeve for coal mining machine and taper sleeve pin shaft assembly

A technology of coal shearer and shaft assembly, applied in the direction of bolts, etc., can solve the problems of reduced reliability of rocker arm and traction connection, increased labor intensity of workers, and damage to the surface of the taper sleeve, so as to reduce the workload of disassembly and replacement, The effect of improving the reliability of the connection and increasing the total bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

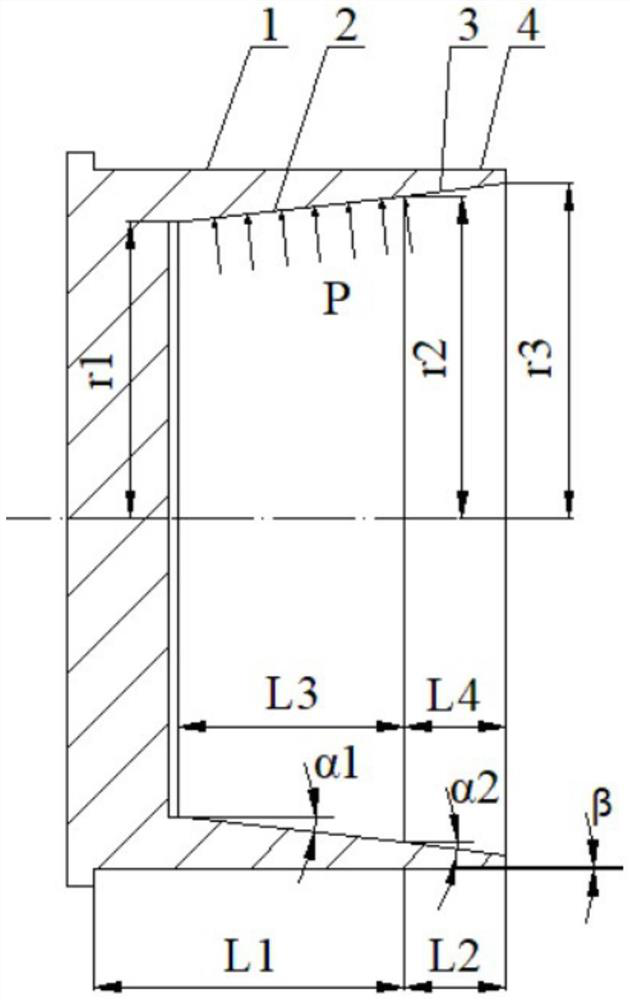

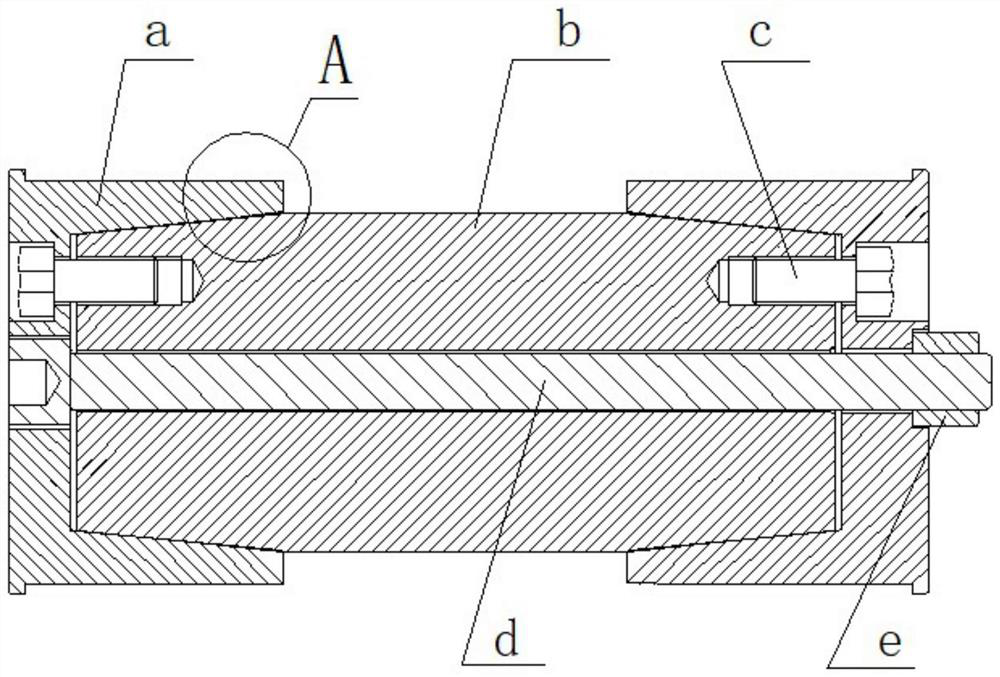

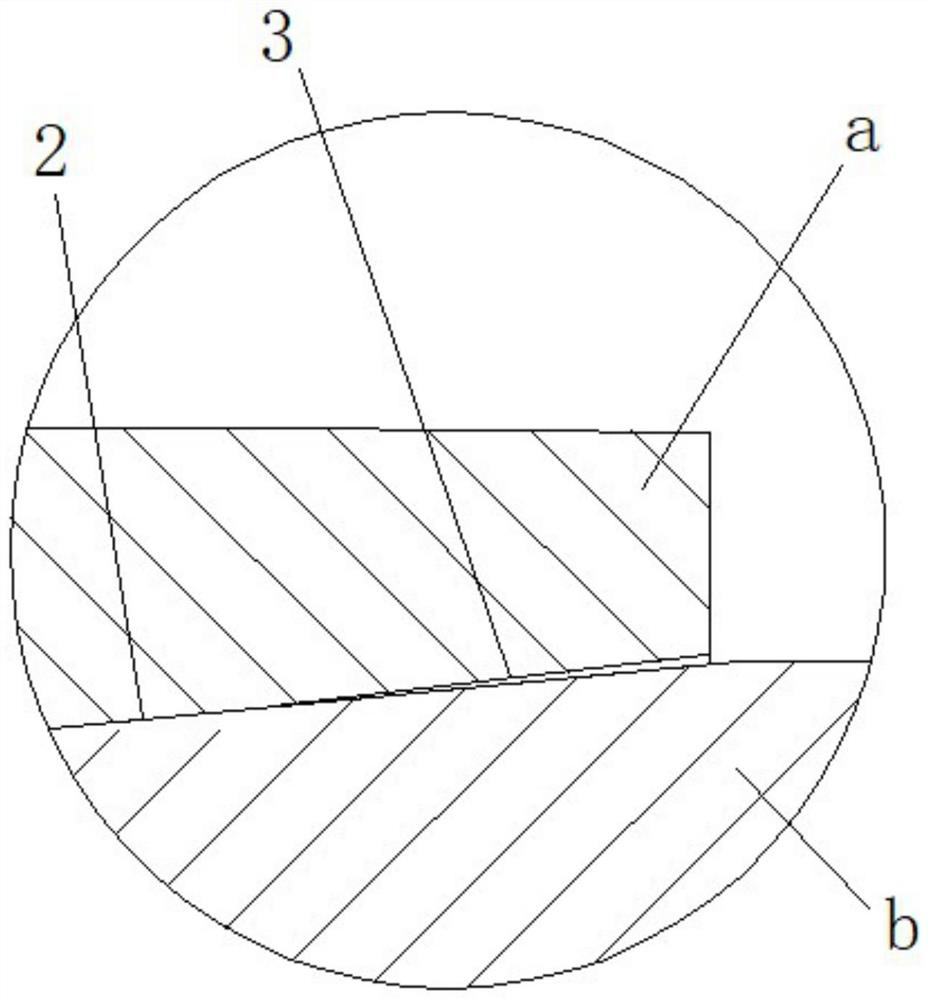

[0023] like Figure 1-3 As shown in the figure, the present invention discloses a tapered sleeve a for a coal shearer (which can be referred to as a tapered sleeve), which is a cylindrical part, and its two ends are respectively closed ends ( figure 1 the left end of the taper sleeve shown) and the open end ( figure 1 The right end of the tapered sleeve shown), the outer revolving surface of its cylinder wall includes the outer first surface 1 and the outer second surface 4 connected left and right, and the inner revolving surface of its cylinder wall includes the inner first surface 2 and The inner second surface 3, the outer second surface and the inner second surface are all adjacent to the open end.

[0024] The outer first surface 1 is a cylindrical surface, and the axial length is L1. When the cone sleeve is embedded in the installation hole of the cone sleeve in the corresponding structural member (usually the traction part of the shearer), the outer first surface The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com