Supporting device and system of air cylinder and control method of supporting system

A support device and support system technology, which is applied in the direction of jet propulsion devices, gas turbine devices, machines/engines, etc., can solve the problem of non-adjustable support stiffness at the cold end of the intake cylinder, and quickly solve vibration problems, reduce operating risks, and reduce operating costs. Risk and Cost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

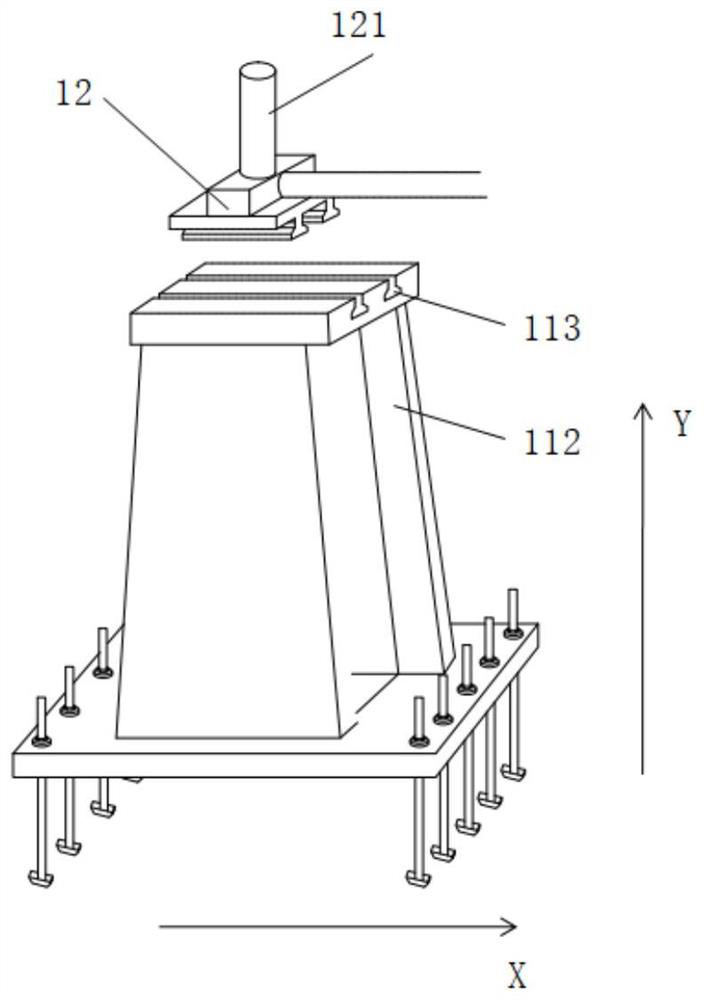

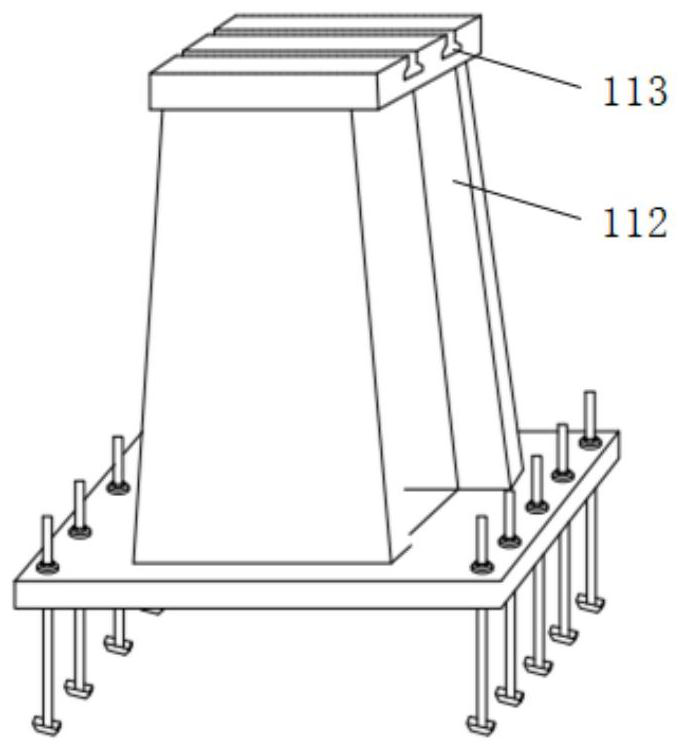

[0048] In the support assembly provided in the first embodiment, the first adjustment part is the first sliding adjustment part 12 , and the position of the first sliding adjustment part 12 on the support body can be adjusted continuously.

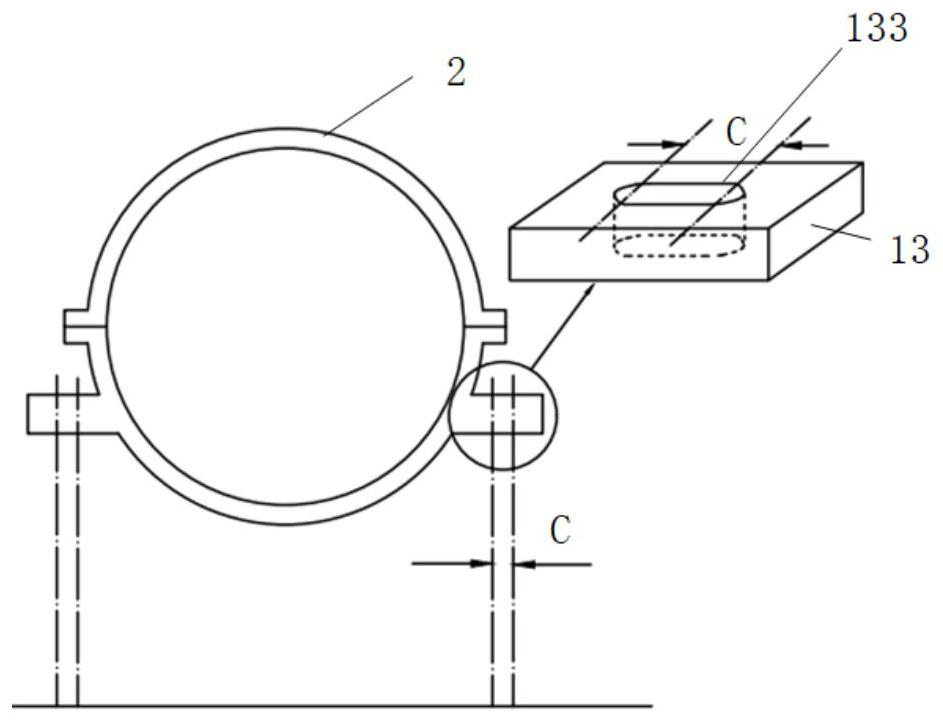

[0049] The third adjusting portion provided on the support body is the third sliding adjusting portion 113, and is provided with two or more inverted T-shaped and inverted trapezoidal sliding grooves. figure 2 The illustrated third sliding adjustment portion 113 is provided with two inverted T-shaped sliding grooves, and the sliding grooves run through the entire top plate. In the installation position of the support assembly, the chute is arranged in the horizontal direction. The corresponding first sliding adjustment portion 12 is provided with two inverted T-shaped sliding blocks, and the sliding blocks are arranged through the bottom plate of the first sliding adjustment portion 12 . The area of the bottom plate of the first slidin...

Embodiment 2

[0053] The second embodiment provides a support assembly in which the position of the first adjustment portion on the support body can be adjusted intermittently. The first adjustment portion is the first intermittent adjustment portion 14, and the position of the first adjustment portion on the support body can be adjusted intermittently. .

[0054] The second embodiment changes the way of adjusting the position of the first adjusting portion on the basis of the first embodiment. like image 3 As shown, the third adjustment part on the support body is the third intermittent adjustment part 114, and is provided with a plurality of second holes 122, and the second holes 122 are threaded holes. like image 3 As shown, the second holes 122 are arranged in 5 rows in the horizontal direction, and each row has 3 holes; a plurality of first holes 111 are arranged on the bottom plate of the corresponding first intermittent adjustment part 14, and the first holes 111 are light holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com