Assembly type building laminated slab wheel buckle type frame body supporting system

A support system and laminated board technology, applied in the direction of construction, building structure, and building material processing, can solve the problem of not being able to adapt to the rhythm of rapid installation of prefabricated buildings, unable to effectively ensure the safety and stability of the frame, and low installation efficiency and other problems, to achieve the effect of fast loading and unloading, saving materials, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

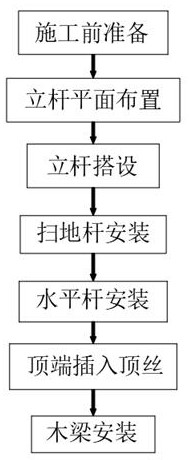

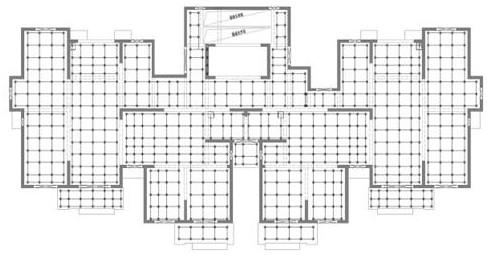

[0051] Refer to the manual attached figure 1 -Attached Figure 4 , Prefabricated building laminated plate wheel buckle frame support system:

[0052] Construction preparations: carefully prepare the construction plan of the wheeled bracket and prepare the construction operation safety and technical disclosure materials. The project department organizes the construction management personnel and production workers to earnestly study the construction drawings and the construction plan of the wheeled bracket, and make detailed instructions for the workers. Written and oral construction safety and technical disclosure work, organize the materials of the wheel-type bracket to enter the site, the wheel-type bracket pole is made of Q235 high-strength steel pipe Φ48×3.2, the main components of the bracket are treated with anti-corrosion, and they are stacked as planned after entering the site. , Arrange the construction team to erect the wheel-type support according to the project req...

Embodiment 2

[0056] On the basis of Example 1, there are the following actual construction cases: The second phase of the Lotus Pond Homeland project is located in the north of Minghuang Road, Yaohai District, Hefei City, and west of the Ershibu River. The planned land area is 87339.6 square meters, and the total construction area is 284586.82 square meters. Square meters (including 70,732.14 square meters of underground garage), the project mainly includes 15 residential buildings (24-30 floors) residential buildings, supporting buildings G1#, G2#, G3# buildings, and there is a ground floor connected to the basement (part of it is a civil air defense basement) )Wait. Project building structure form: prefabricated (partially cast-in-place) reinforced concrete shear wall structure; 15 high-rise buildings are built by residential industrialization, and the prefabricated assembly rate is not less than 50%, of which the standard floors of 1# and 15# are made of laminated panels Wheel buckle fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com