Silica sol composite graphite felt as well as preparation method and application thereof

A technology of composite graphite and silica sol, which is applied in the field of graphite felt, can solve the problems of poor oxidation resistance, poor high temperature resistance, and poor heat preservation of viscose-based graphite felt, and achieve the anti-oxidation performance and heat preservation effect of non-powdering and slag removal good, strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

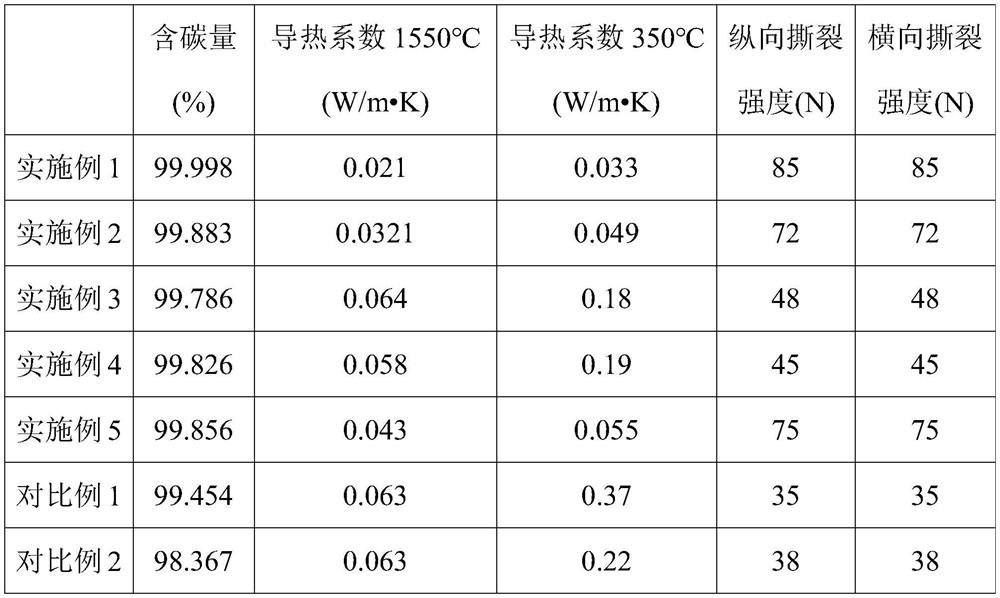

Examples

Embodiment 1

[0048] A preparation method of silica sol composite graphite felt, comprising the following steps:

[0049] (1) Immerse the viscose-based graphite felt (Liaoning Xinghui Carbon Material Technology Co., Ltd., URGF-GF-TP3 / 2) into modified silica sol (pH 7, made of 3% dodecyltrimethoxysilane) and 97% of the silica sol provided by Hubei Zhenghe Technology Co., Ltd.) for 30 min, using a rolling mill with a line speed of 30 m / min to carry out two-dipping and two-rolling treatment, and the over-rolling ratio was 70% to obtain a modified graphite felt;

[0050] (2) drying the modified graphite felt obtained in step (1) in a drying oven at 180°C for 50 min, cooling to room temperature, and heating the cooled modified graphite felt at a heating rate of 50°C / min for the first time to 600°C, hold the temperature for 30min, heat to 800°C for the second time according to the heating rate of 10°C / min, heat to 1600°C for the third time according to the heating rate of 5°C / min, keep the temper...

Embodiment 2

[0052] A preparation method of silica sol composite graphite felt, comprising the following steps:

[0053] (1) Immerse the viscose-based graphite felt (Liaoning Xinghui Carbon Material Technology Co., Ltd., URGF-GF-TP3 / 2) into a modified silica sol (made of 3% dodecyltrimethoxysilane and 97% Hubei The composition of silica sol provided by Zhenghe Technology Co., Ltd.) was used for 60min in a rolling mill with a line speed of 35m / min to carry out two-dipping and two-rolling treatment, and the residual ratio was 75% to obtain a modified graphite felt;

[0054] (2) drying the modified graphite felt obtained in step (1) in a drying oven at 280° C. for 40 min, cooling to room temperature, and heating the cooled modified graphite felt for the first time according to a heating rate of 60° C. / min to 650°C, hold for 20min, heat to 850°C for the second time according to the heating rate of 12°C / min, heat to 1650°C for the third time according to the heating rate of 6°C / min, hold for 10...

Embodiment 3

[0056] A preparation method of a silica sol composite graphite felt, the difference from Example 1 is that the one-dipping and one-rolling process is used to replace the two-dipping and two-rolling treatment process, and the over-rolling ratio is 70%, and other components, parameters and steps are the same as Example 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com