Automated logistics storage rack with sorting mechanism

A shelf and storage technology, applied in the field of automated logistics storage shelves, can solve the problems of poor stability of storage shelves, slow sorting efficiency, uneven weight distribution, etc., and achieve the effect of easy search and access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

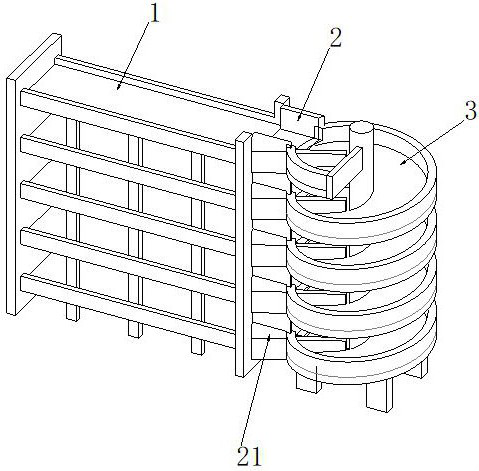

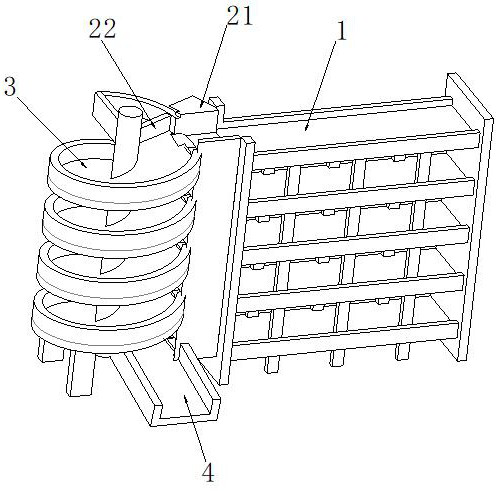

[0039] see Figure 1-4 As shown in the figure, the automatic logistics storage rack with sorting mechanism includes storage rack body 1, screw elevator body 3 and feeding plate 4. The outer side wall of storage rack body 1 is provided with screw elevator body 3, and the back of screw elevator body 3 is provided with screw elevator body 3. The end is connected with a feeding plate 4;

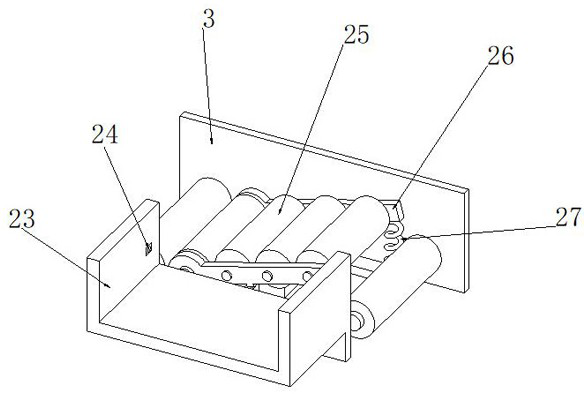

[0040] The outer side wall of the screw elevator body 3 is provided with a weighing mechanism 2 at the position corresponding to the storage shelf body 1. The weighing mechanism 2 includes a discharge plate 23, and an infrared distance sensor 24 is connected to the inner wall of the discharge plate 23 near the position of the screw elevator body 3. The inner side wall of the discharge plate 23 is provided with an installation groove at the position corresponding to the infrared distance sensor 24. The infrared distance sensor 24 is installed on the inside of the installation groove and will not b...

Embodiment 2

[0044] see Figure 5-6 As shown, the upper surface of the storage rack body 1 is provided with a rack transmission mechanism 5, and the rack transmission mechanism 5 includes a support roller 52. A speed control box is connected to the position of the back surface of the storage rack body 1 corresponding to the support roller 52, and the rear surface of the speed control box is connected. A drive motor is connected, and the output end of the speed control box is connected with the support shaft of the support roller 52, so that the support roller 52 is driven by the drive motor to rotate, and the speed control box can adjust the rotation speed of the support roller 52, and the support roller 52 Both ends are connected with connecting gears 56, and a rotating slot 51 is opened inside the storage shelf body 1 at the position corresponding to the connecting gear 56. The inner side wall of the rotating slot 51 is connected with a first transmission gear 57 through a rotating shaft ...

Embodiment 3

[0048] see Figure 7-9 As shown, the lower surface of the storage shelf body 1 is provided with a cleaning mechanism 6, and the cleaning mechanism 6 includes a dust box 62. Both sides of the inner side wall of the dust box 62 are rotatably connected with a transverse reciprocating screw 67, and both sides of the outer side wall of the transverse reciprocating screw 67 A transverse gear 63 is connected, both ends of the transverse reciprocating screw 67 are connected with transverse gears 63, and a cleaning brush 61 is slidably connected to the side of the lateral reciprocating screw 67 close to the transverse gear 63, and the cleaning brush 61 is connected to the two transverse reciprocating The lead screw 67 moves, and the two transverse reciprocating screws 67 are driven and rotated by gears of the same structure and size, so that the two transverse reciprocating screws 67 rotate at the same speed. The support seat 64, the inner side wall of the support seat 64 is rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com