All-weather self-adaptive live working machine with rainproof structure

A live working, all-weather technology, used in climate change adaptation, manipulators, electrical components, etc., can solve the problem that live working robots cannot be practical in rainy days, increase the insulation protection of the working position, etc., to ensure reliability, increase insulation protection, increase The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

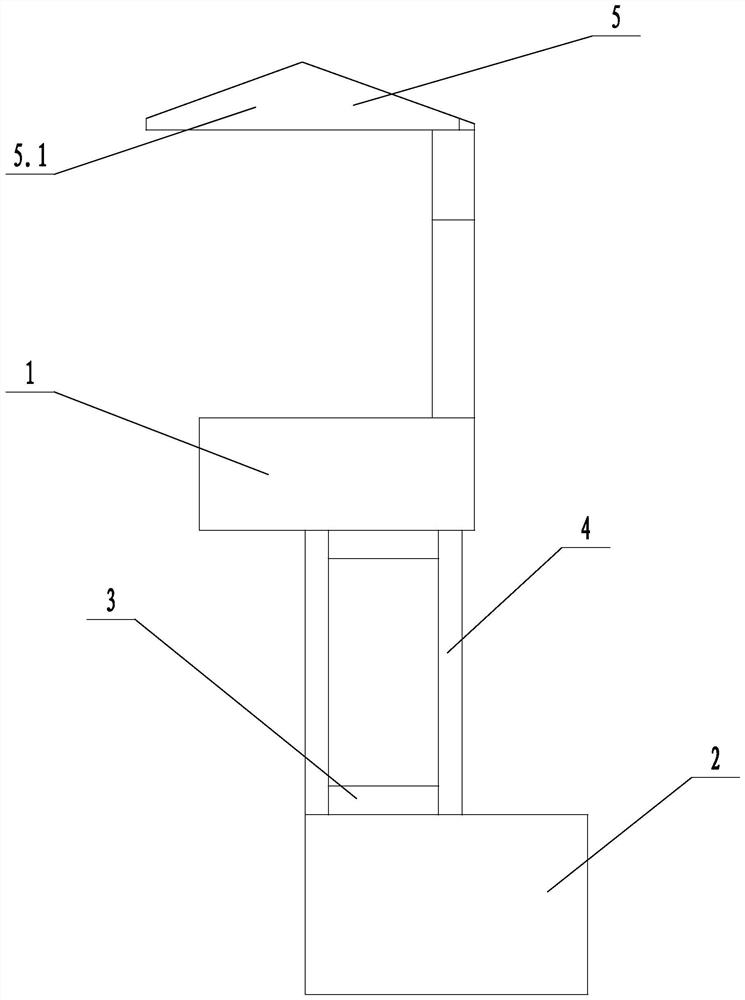

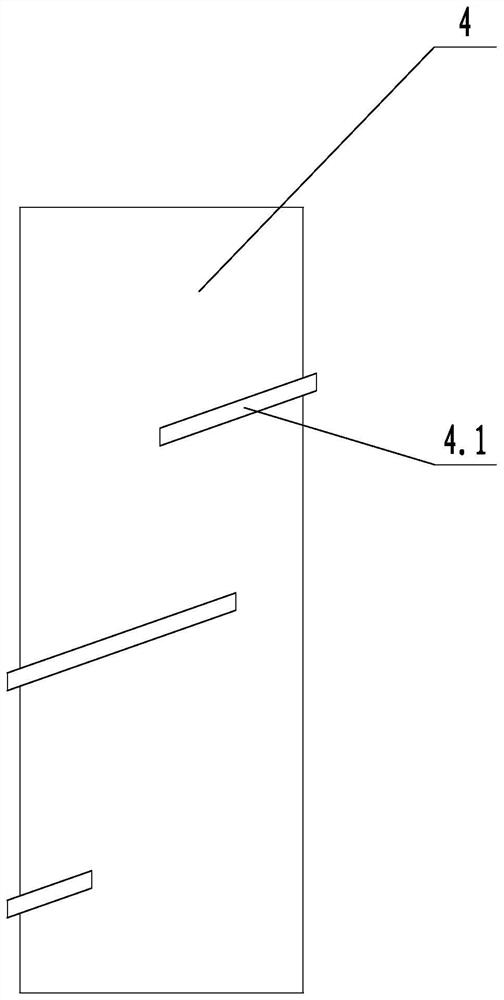

[0027] like figure 1 and figure 2 As shown, an all-weather self-adaptive live working machine with a rainproof structure includes a machine body 1, a lifting platform 2 and an insulating frame 3, the machine body 1 is fixed with the insulating frame 3, and the insulating frame 3 is fixed with the lifting platform 2 , the insulating frame 3 includes several insulating rods 4 arranged side by side, such as image 3 and Figure 4 As shown, the outer side wall of the insulating rod 4 is provided with a plurality of water-breaking guide bars 4.1 inclined relative to the axis of the insulating rod 4 . A plurality of water-breaking guide bars 4.1 are arranged along the axial direction of the insulating rod 4 , and adjacent water-breaking guide bars 4.1 are arranged staggered on the axial projection plane of the insulating rod 4 . The lower ends of the plurality of water-breaking guide bars 4.1 are suspended from the insulating rod 4. The height of the water-breaking guide bar 4....

Embodiment 2

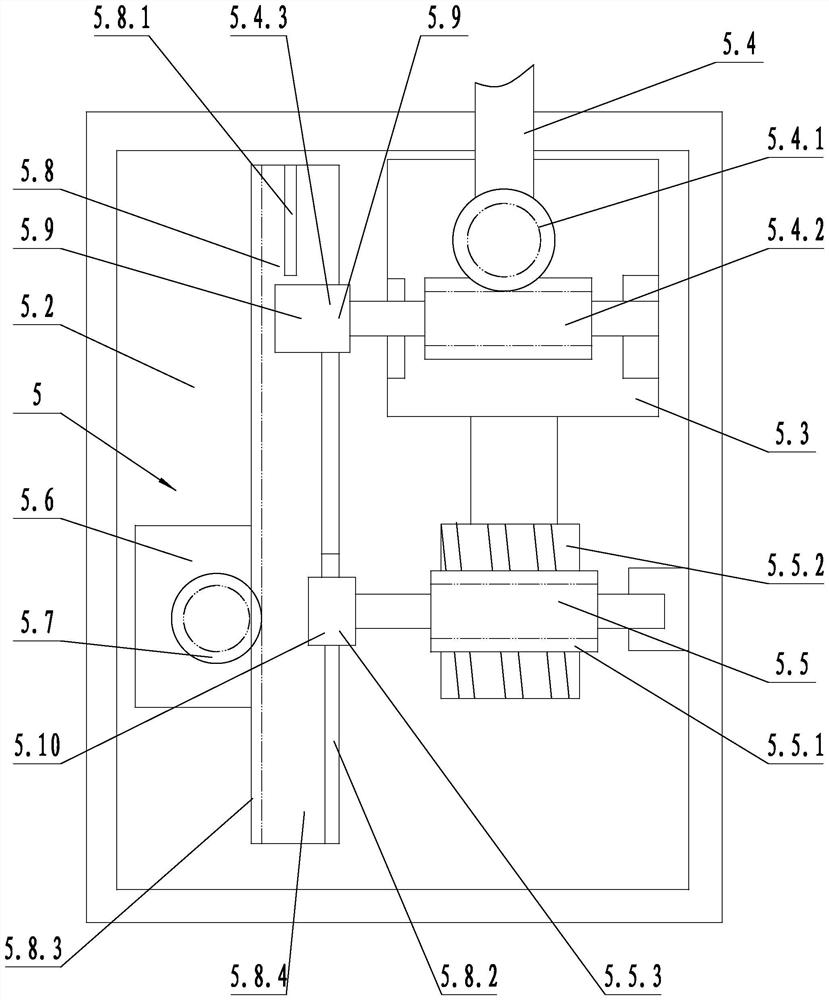

[0031] like figure 2 As shown, on the basis of Embodiment 1, the turning mechanism 5.4 includes a turning worm gear 5.4.1, a turning worm 5.4.2, a first rotating drive member 5.4.3, and the awning 5.1 rotates with the horizontal turret 5.3 through the turning shaft Connected, the overturning worm gear 5.4.1 is coaxially fixed with the overturning shaft, the overturning worm 5.4.2 is rotatably connected with the horizontal turret 5.3, the overturning worm wheel 5.4.1 is engaged with the overturning worm 5.4.2, and the first rotating drive member 5.4.3 drives the overturning The worm 5.4.2 rotates; the rotating mechanism 5.5 includes a rotating worm wheel 5.5.1, a rotating worm 5.5.2 and a second rotating drive member 5.5.3, the rotating worm wheel 5.5.1 is coaxially fixed with the horizontal turret 5.3, and the rotating worm 5.5 .2 is rotatably connected with the fixed frame 5.2, the rotating worm gear 5.5.1 is engaged with the rotating worm 5.5.2, and the second rotating driv...

Embodiment 3

[0035] On the basis of Embodiment 1, the machine body 1 includes a casing, the casing is provided with a cooling ventilation inlet and a cooling ventilation outlet, a dehumidification pipe is arranged outside the cooling ventilation inlet, a desiccant is arranged in the dehumidifying pipe, and a fan is arranged inside the cooling ventilation inlet . The dehumidification pipe is provided with a semiconductor dehumidification device, and the semiconductor dehumidification device is arranged outside the desiccant. In the above technical solution, the desiccant can absorb water vapor in the air, reduce the air humidity blown into the robot, effectively dissipate heat to the machine body 1 in a high temperature and high humidity environment, and reduce the impact of high humidity air on the inside of the machine.

[0036] The beneficial effects of the present invention are: (1) reduce or prevent rainwater from entering the working position on rainy days, increase the insulation pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com