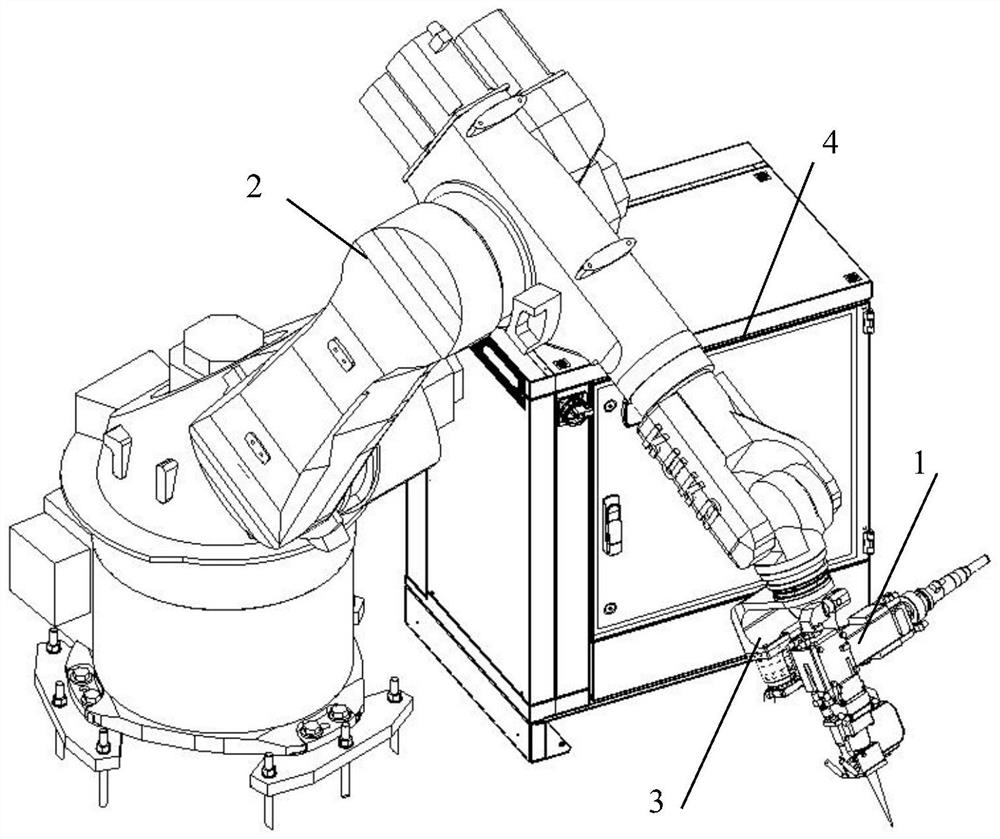

High-speed welding macro-micro robot composite welding seam tracking system

A micro-robot and composite welding seam technology, applied in the field of welding seam tracking system, can solve the problems of robot tracking process jitter, untimely welding seam tracking response, slow robot tracking response, etc., so as to improve the welding seam tracking response frequency and tracking accuracy , the structure is simple and compact, the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings. The specific embodiments described are only used to explain the present invention, and are not intended to limit the present invention.

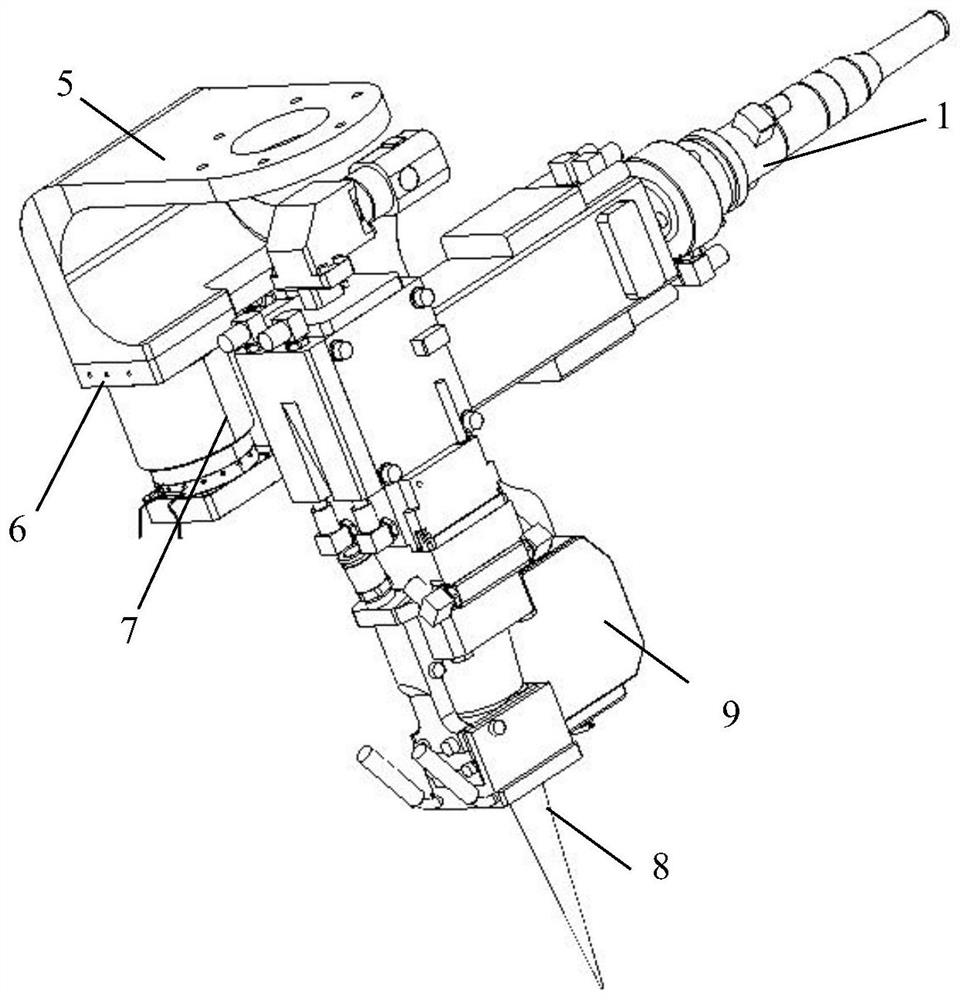

[0030] The micro-tracking device of the present invention is assembled, and laser tools are used for welding, and finally installed to the end of the industrial robot.

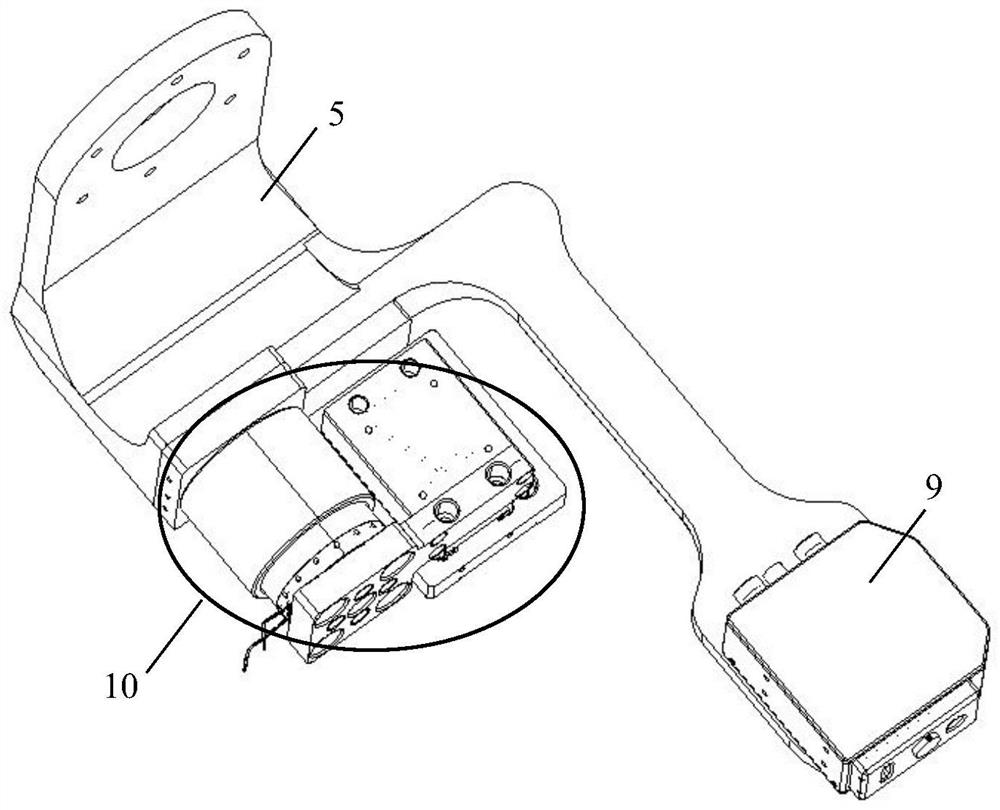

[0031] In the connection frame 5, the robot flange connection end face 11 is machined with mounting holes corresponding to the end flange of the sixth axis of the robot, and the robot flange connection end face 11 is used for connection with the flange of the robot 2 through bolts. The voice coil motor fixing frame connecting end face 12 is processed with mounting holes corresponding to the voice coil motor fixing frame 6 , and the voice coil motor fixing frame connecting end face 12 is connected with the voice coil motor fixing frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com