Blast furnace flue gas multi-stage guide purification device and implementation method

A purification device and flue gas technology, applied in the field of flue purification, can solve the problems of large sewage treatment capacity, difficult installation, and excessively long flue, and achieve the effects of improving purification capacity, increasing barrier force, and reducing impurity particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

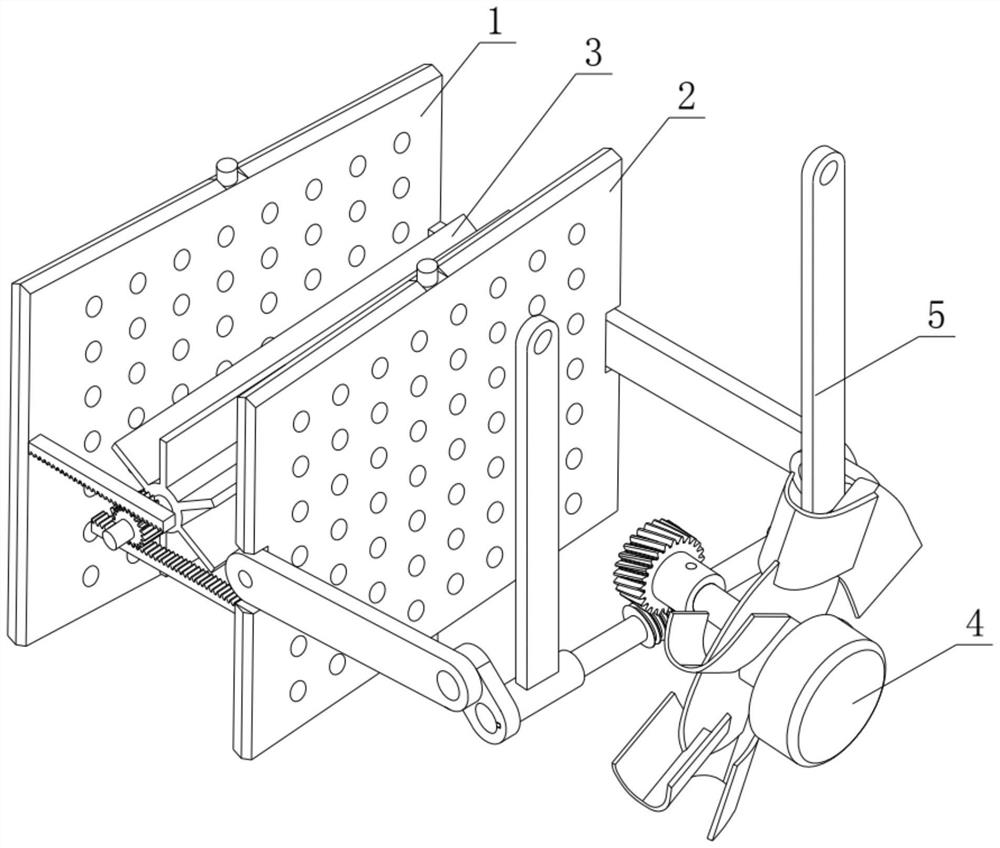

[0046] In order to better demonstrate the implementation process of the blast furnace flue gas multi-stage guide purification device, the present embodiment now proposes an implementation method of the blast furnace flue gas multi-stage guide purification device, including the following steps:

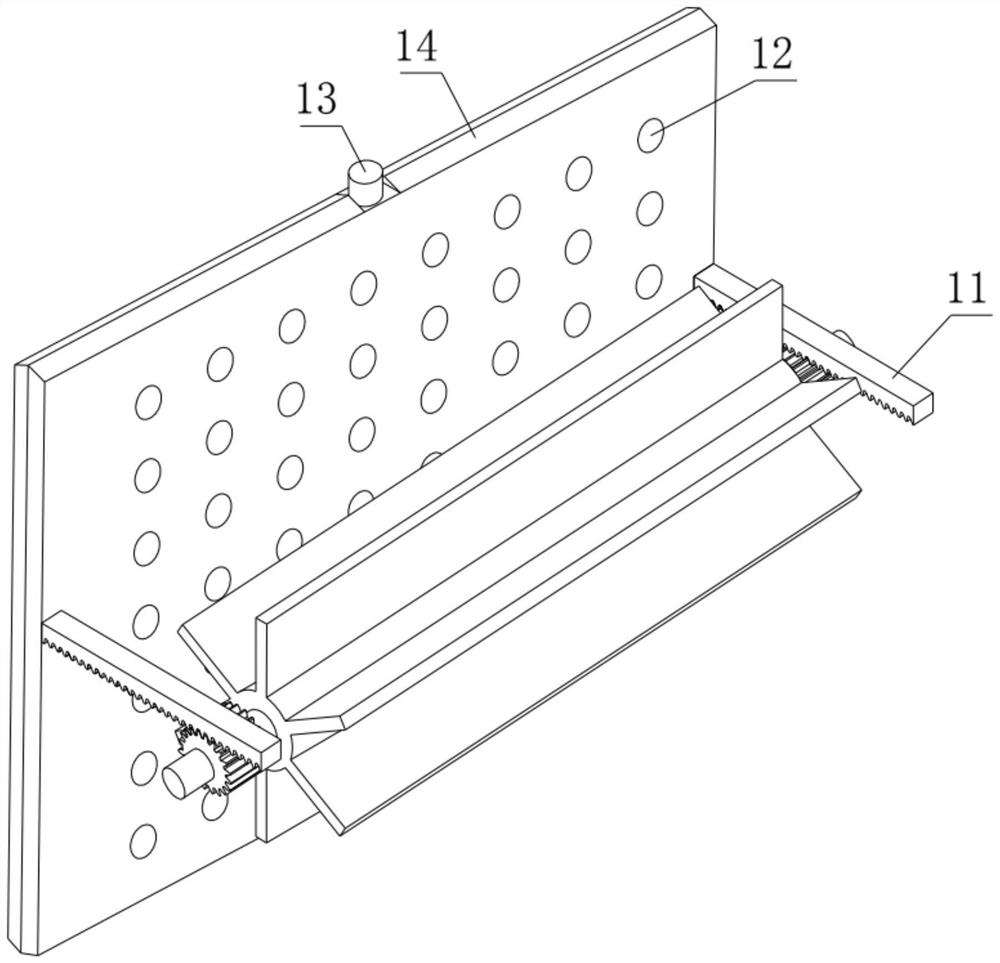

[0047] Step 1: Install the purification device in the blast furnace flue, the primary barrier 1 and the secondary barrier 2 are respectively movably connected to the blast furnace flue through the short shaft 13, and the driving motor 42 works to drive the fan main body 41 to rotate, which generates in the blast furnace flue. Negative pressure, attracting flue gas to enter from the end of the blast furnace flue near the primary barrier plate 1;

[0048] Step 2: The worm wheel 431 drives the worm 511 to rotate, thereby controlling the long rotating shaft 51 to work, and through the action of the rotating rod 53 and connecting the tie rod 54, the secondary barrier plate 2 rotates around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com