Novel automatic hair fishing method for environmental leather industry

A technology for the leather industry and the environment, applied in the field of hair-water separation, which can solve problems such as labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

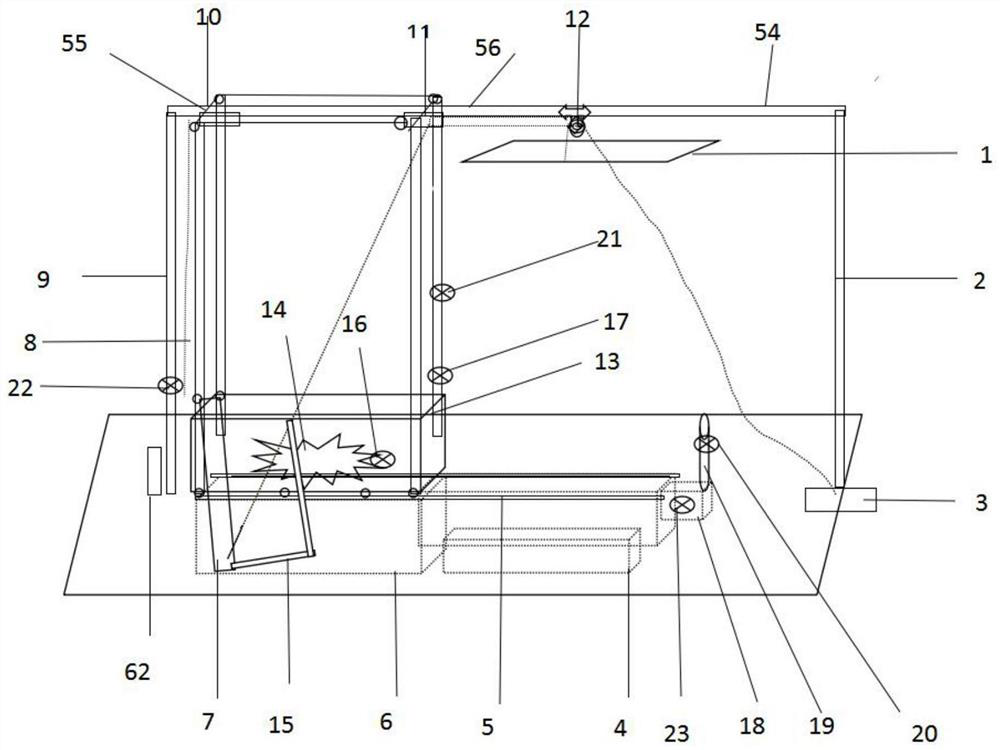

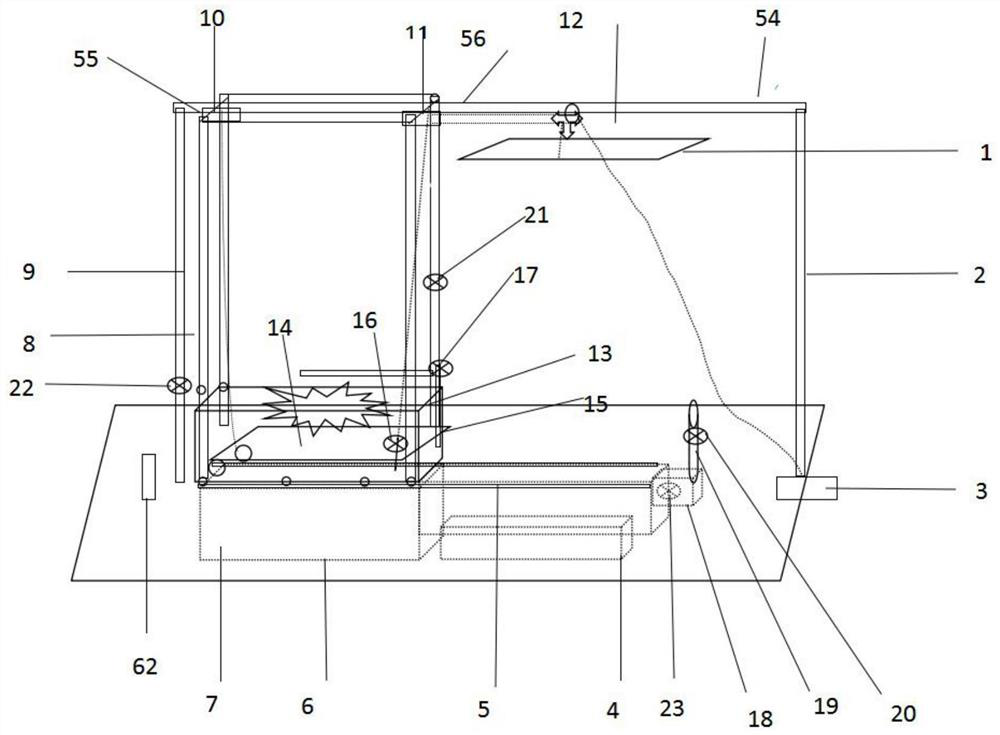

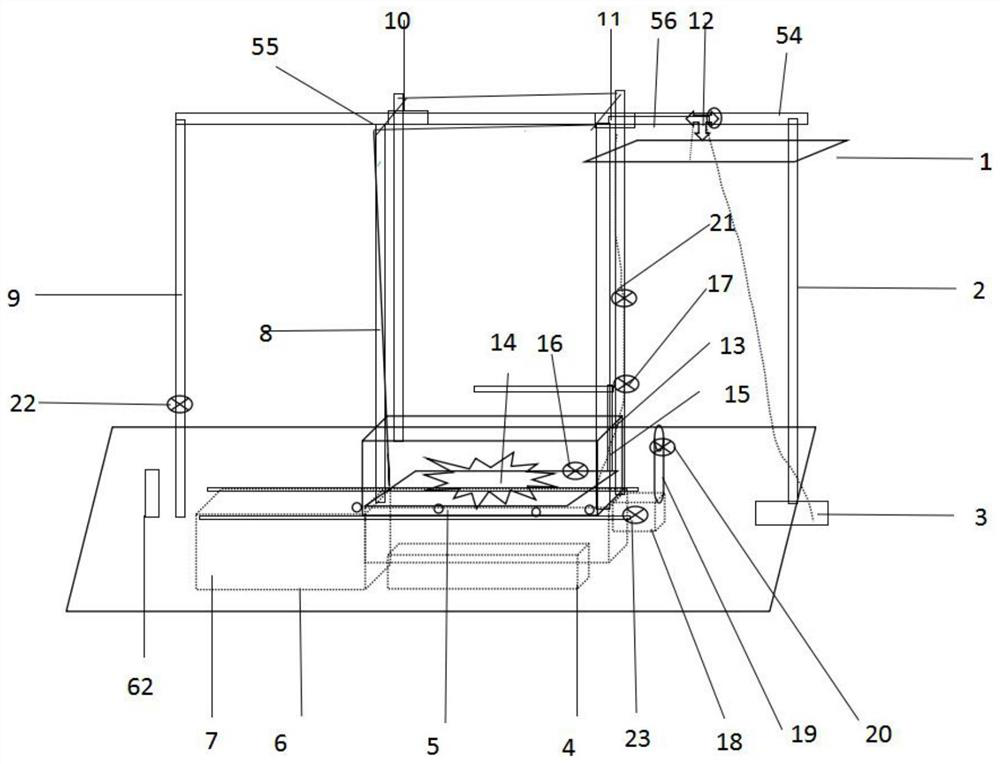

Embodiment 1

[0024] [Example 1] A new type of automatic scouring method for environmental leather industry, including a collection system, a transportation system, a control system, an on-line monitoring device, a separation tank 6, a compression tank 4, and the collection system is composed of a collection box 13 and a collection plate 7, The lower end of the collection box 13 is arranged on the front upper end of the separation pool 6 and the compression pool 4, and in the first conveyor roller 5 installed on the upper end of the back, and wheels are installed on both sides of the left end of the collection plate 7. In the second conveying track 8, the first elevator 10 and the second elevator 11 are installed in the transportation system, which are connected to the collection system.

Embodiment 2

[0025] [Example 2] Working process

[0026] first step hydration

[0027] The second water level sensor 61 in the compression tank 4 controls the water in the compression tank 4 to flow into the separation tank 6 by receiving the signal of the water level in the compression tank 4. The water level sensor in the separation tank 6 receives the water level sensor in the separation tank 6. The high and low signals of the middle water level control the tap water to enter the separation tank 6 and maintain the water level of the separation tank.

[0028] The second step to salvage

[0029] The collection plate moves upward and the hairy matter floats and gathers on the water surface, the first normally open sensor 24 receives the signal that the object is blocked, and controls the first control button 25 to press the first elevator 10 "up" key, the collecting plate 7 is lifted up to the horizontal direction.

[0030] The collection system moves the first normally closed sensor 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com