Electromechanical product assembly error online prediction method

A technology for assembly errors and electromechanical products, applied in prediction, neural learning methods, computer components, etc., to achieve the effects of increasing inference speed, reducing distance, and improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further introduced below with reference to the accompanying drawings and specific embodiments.

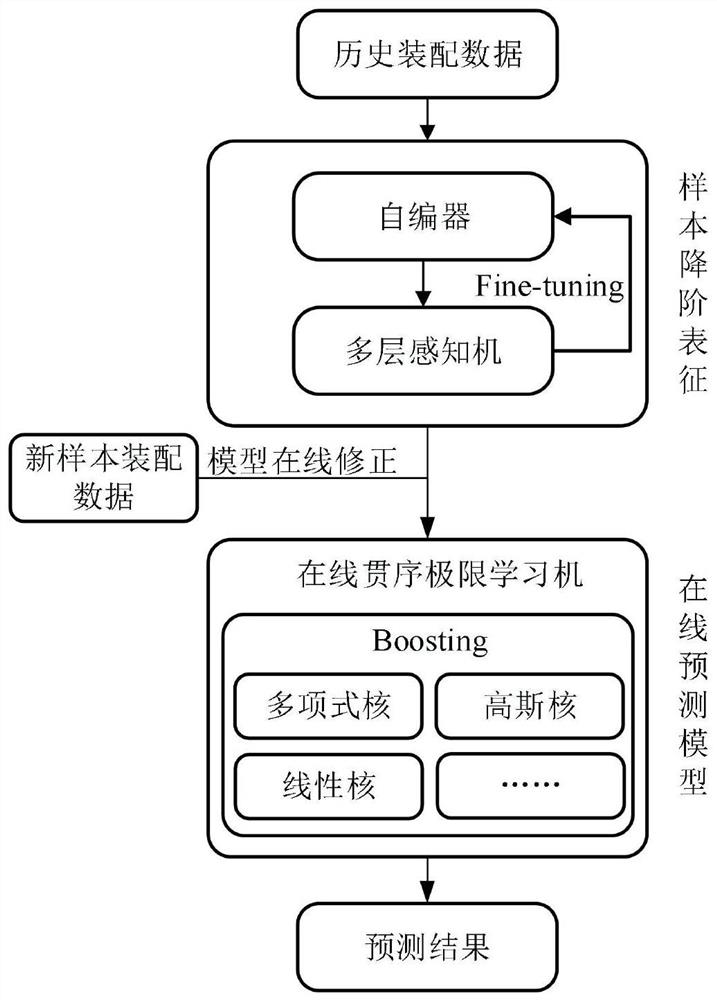

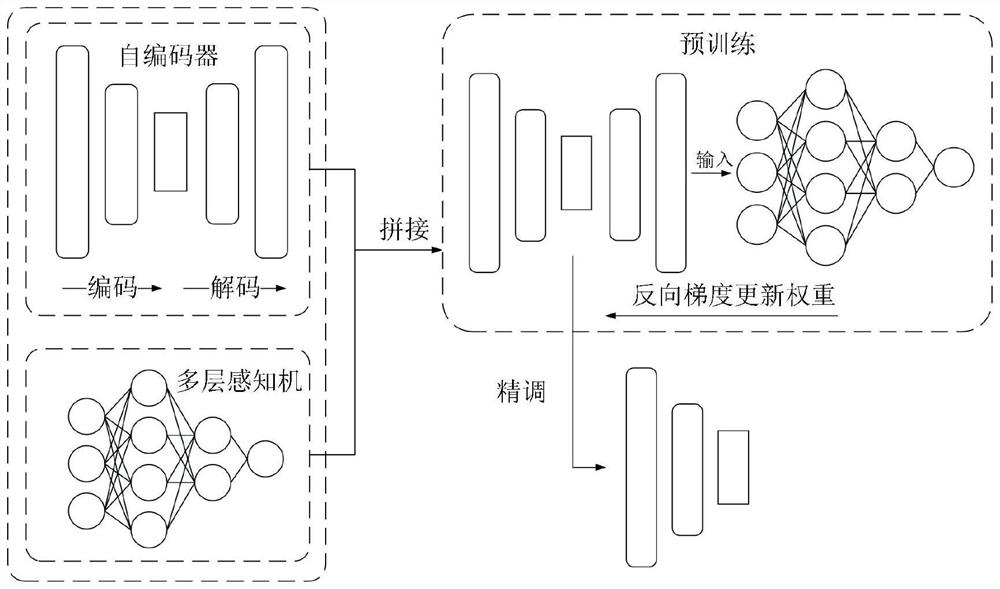

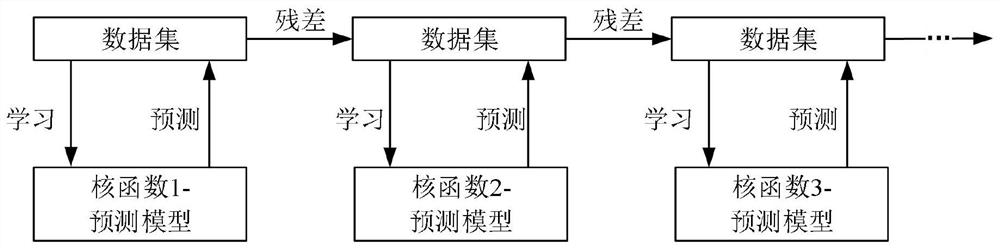

[0017] attached figure 1 It is a flow chart of an on-line prediction method of assembly error based on autoencoder and Boosting-OSKELM algorithm. The present invention includes the following steps:

[0018] Step 1. Build a training sample dataset:

[0019] According to the historical data of a certain process, the corresponding data set is constructed, 80% of the data set is divided into training set D, and the remaining 20% is divided into test set E. The difference between the two is only in the amount of sample data, but in the characteristics The structure and output structure are consistent.

[0020] training set X is the process input, Y is the error output, and the training set matrix is as follows:

[0021]

[0022] In the training set matrix, each row is a sample point, N is the number of samples, M 1 with M 2 are the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com