Tough connecting structure for overhead vertical frame wharf and overhead slope ramp wharf

A frame wharf and connection structure technology, applied in the field of frame wharves, can solve the problems of weak earthquake resistance, endangering the safety of wharf structures, small displacement of seismic joints, etc., and achieve the effect of simple structure, good use effect, and normal load bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

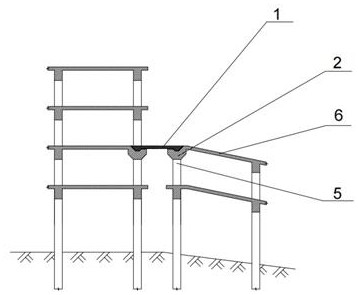

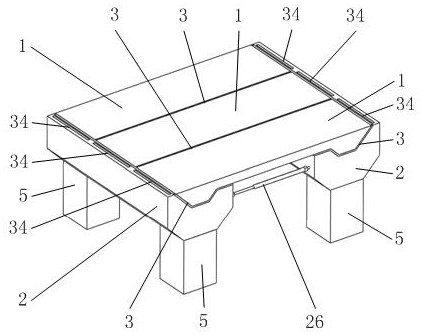

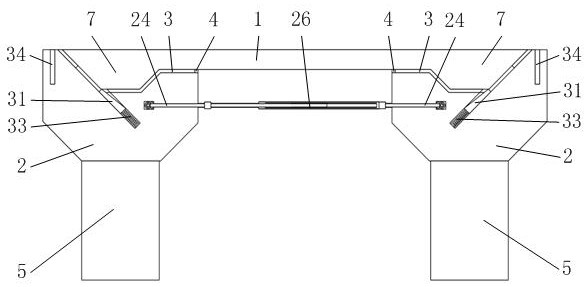

[0042] The accompanying drawings are schematic diagrams of the implementation of the present invention, so as to facilitate the understanding of the operation principle of the structure. The specific product structure and proportions can be determined according to the use environment and conventional techniques.

[0043] like figure 1 , 2 As shown, it includes a simply supported plate, a bottom beam, a polyurea cushion, a frame column, a lever, a rotating shaft B, a universal joint, and a telescopic rod, such as figure 2 , 10 As shown in the figure, the frame columns at the joint of the vertical wharf and the sloping wharf are all poured with concrete bottom beams, and the top of the bottom beam has a groove with an inverted trapezoid cross-section; as in figure 1 , 10 As shown, the height of the slope C on the side of the groove close to the floor is greater than the height of the slope D on the side away from the floor; such as figure 2 , 3 As shown in , 11, there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com