Method for preparing potassium ferrate and cementing material from waste incineration fly ash and iron tailings

A technology for waste incineration fly ash and potassium ferrate, applied in chemical instruments and methods, iron compounds, cement production, etc. high coagulation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Effect of mass ratio of iron tailing powder and waste incineration fly ash on potassium ferrate conversion rate, chlorine removal rate and cementing activity of cementitious materials

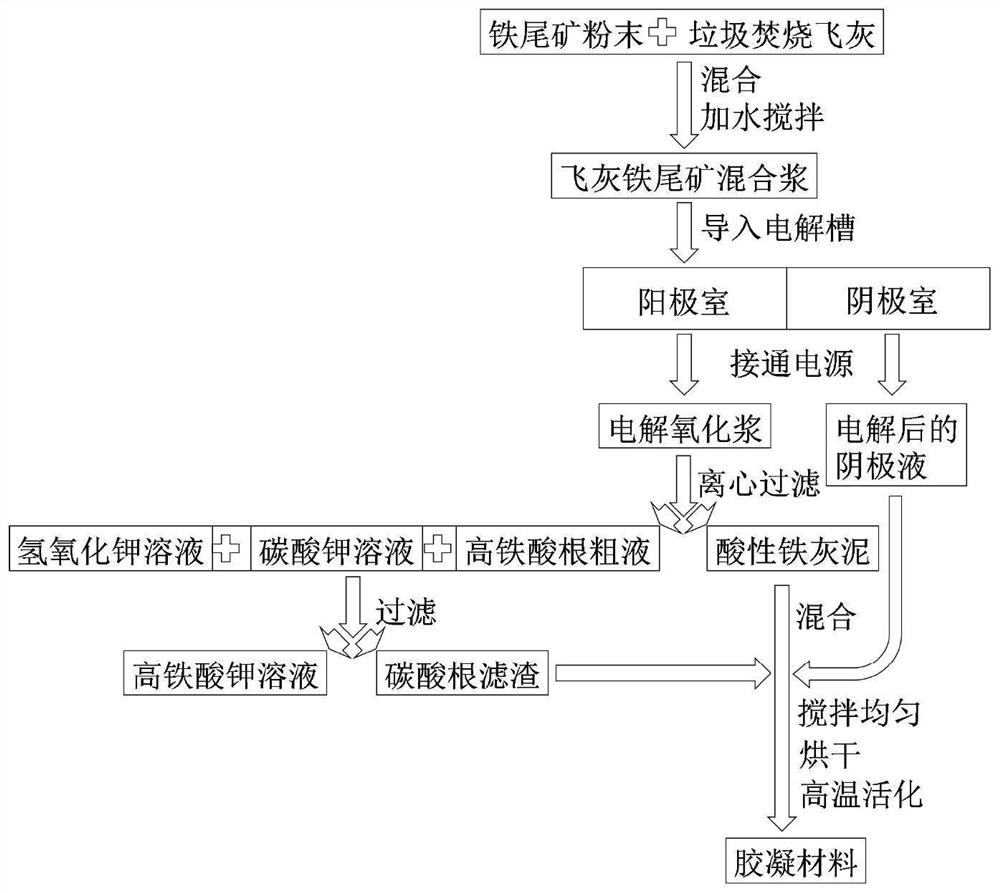

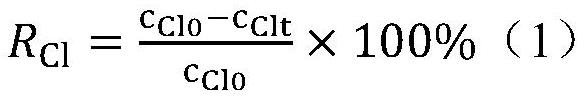

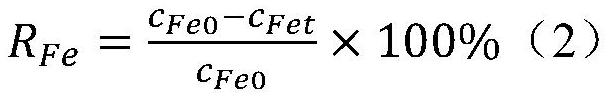

[0021] Preparation of potassium ferrate and cementitious materials: such as figure 1 As shown, according to the mass ratio of 0.25:1, 0.35:1, 0.45:1, 0.5:1, 1.0:1, 1.5:1, 1.6:1, 1.8:1, 2.0:1, iron tailings powder and garbage were respectively The incineration fly ash is mixed, and water is added to stir evenly to obtain a mixed slurry of fly ash and iron tailings, wherein the liquid-solid ratio of water, iron tailings powder and the mixture of waste incineration fly ash is 1:1 mL / g; Placed in the anode chamber of the electrolytic cell, start the DC power supply to carry out electrolysis for 5 hours, wherein the current threshold is set to 50A, and the voltage threshold is set to 20V. The catholyte; the electrolytic oxidation slurry was centrifuged and filtered to obtain ferrate crude so...

Embodiment 2

[0033] Effect of volume ratio of potassium hydroxide solution, potassium carbonate solution and crude ferrate solution on potassium ferrate iron conversion rate, chlorine removal rate and gelation activity of gelling materials

[0034] Preparation of potassium ferrate and cementitious material: according to the mass ratio of 1.5:1, the iron tailings powder and the waste incineration fly ash are mixed, and water is added to stir evenly to obtain a mixed slurry of fly ash iron tailings, in which water, iron tailings powder and The liquid-solid ratio of the waste incineration fly ash mixture is 2:1 mL / g; the fly ash iron tailings mixed slurry is placed in the anode chamber of the electrolytic cell, and the DC power supply is turned on for electrolysis for 3 hours. The current threshold is set to 550A, and the voltage threshold is set to 110V, after the electrolysis, the electrolytic oxide slurry and the electrolyzed catholyte were obtained from the anode chamber and the cathode ch...

Embodiment 3

[0040] Effect of activation temperature on potassium ferrate iron conversion rate, chlorine removal rate and gelation activity of cementitious materials

[0041] Preparation of potassium ferrate and cementitious material: according to the mass ratio of 1.5:1, the iron tailings powder and the waste incineration fly ash are mixed, and water is added to stir evenly to obtain a mixed slurry of fly ash iron tailings, in which water, iron tailings powder and The liquid-solid ratio of the waste incineration fly ash mixture is 3:1 mL / g; the fly ash-iron tailings mixed slurry is placed in the anode chamber of the electrolytic cell, and the DC power supply is started for electrolysis for 1 hour, where the current threshold is set to 1050A, and the voltage threshold is set to 200V, after the electrolysis is completed, the electrolytic oxide slurry and the electrolyzed catholyte are respectively obtained from the anode chamber and the cathode chamber of the electrolytic cell; the electroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com