Machine tool automatic feeding and discharging two-way forklift system and automatic production line

A technology of machine tools and forklifts, which is applied to automatic machine tool loading and unloading two-way forklift systems and automated production lines. It can solve problems such as low work efficiency, many safety hazards, and high safety risks, and achieve the effect of reducing work intensity and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

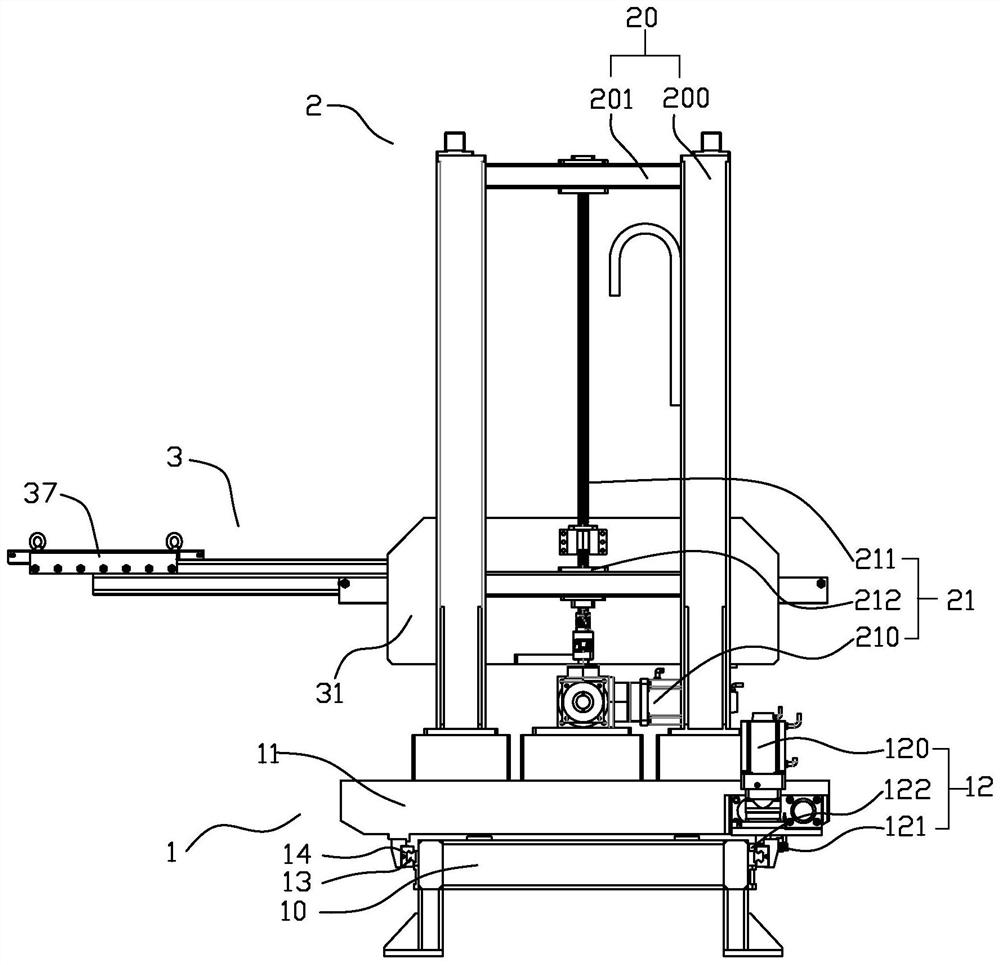

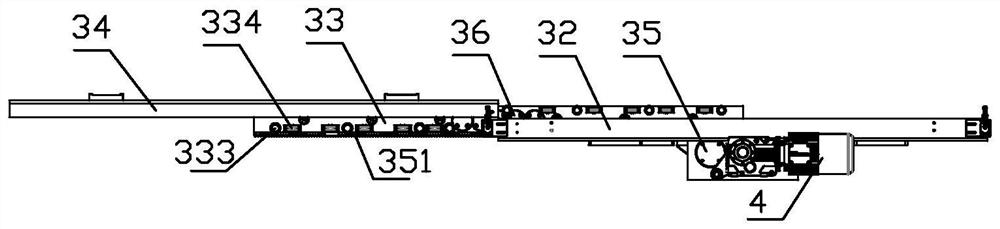

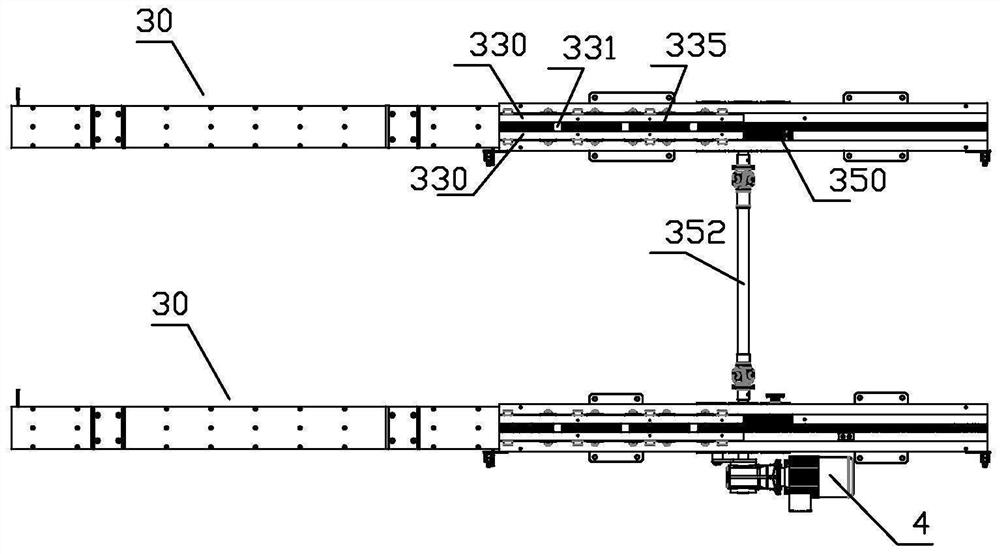

[0044] like figure 1 , figure 2 and image 3 Shown is a machine tool automatic loading and unloading bidirectional forklift system disclosed in the present invention, including an X-axis unit 1, a Z-axis unit 2 and a Y-axis unit 3;

[0045] The X-axis unit 1 includes a fixed platform 10, an X-axis slide 11 disposed on the fixed platform 10 and capable of horizontal movement along the X-axis direction, and an X-axis slide for driving the X-axis slide 11 to move horizontally. seat drive 12;

[0046] The Z-axis unit 2 includes a door-shaped frame 20 arranged on the X-axis sliding seat 11 and a Z-direction drive arranged on the door-shaped frame 20 for driving the Y-axis unit 3 to rise and fall along the Z-axis direction. device 21;

[0047] Specifically, the portal frame 20 includes four portal frame uprights 200 arranged opposite to each other, the portal frame uprights 200 are connected by a cross beam 201, and two portal frame uprights 200 located on the same side along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com