Hyperbranched PBAT polyester and preparation method thereof

A technology of polyester and branched monomers, applied in the field of hyperbranched PBAT polyester and its preparation, can solve the problems of increased melt viscosity, low utilization rate of auxiliary agents, less active carboxyl groups, etc. The effect of high rate and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation steps of partially blocked third-generation HBPE are as follows:

[0052] Synthesis of second-generation HBPE: Put the nuclear unit (pentaerythritol or trimethylolpropane) and 2,2-dihydroxypropionic acid into the reactor, under the protection of nitrogen, heat up to 130°C while stirring, and then put in tetrabutyl titanate Esters, constant temperature reaction, when the acid value of the reaction system drops to 5mgKOH / g, the system is vacuumed for 1 hour, and the water produced by the reaction is extracted.

[0053] Synthesis of third-generation HBPE: Continue to feed nitrogen, add weighed 2,2-dihydroxypropionic acid and tetrabutyl titanate, and react at a constant temperature of 130°C. When the acid value of the reaction system drops to 5mgKOH / g, capping .

[0054] Partially capped HBPE synthesis: continue to feed nitrogen, add a certain amount of propionic acid, and react at a constant temperature of 140 ° C. When the acid value of the reaction syste...

Embodiment 5

[0057] Partially blocked three generations of HBPE formula table in embodiment 5:

[0058]

[0059] The index parameters of the partially blocked third-generation HBPE prepared according to the above formula and steps are as follows:

[0060]

Embodiment 1

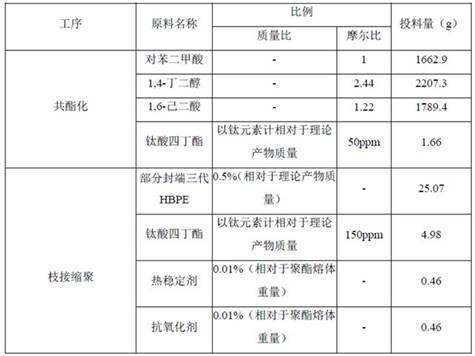

[0063] Table 1 Example 1 Feeding table

[0064]

[0065] (1) Esterification reaction:

[0066] Add the weighed terephthalic acid, 1,4-butanediol and adipic acid into the esterification kettle, turn on the heating, stir evenly, raise the temperature to 180°C, and carry out the esterification and dehydration reaction for 2 hours. The amount of water reached the theoretical value of 799.9g, and no more water was distilled out.

[0067] (2) Graft polycondensation: The completed co-esterification product, 5.01g of partially blocked third-generation HBPE, tetrabutyl titanate, triphenyl phosphate and 2,6-di-tert-butyl-4-methylphenol are added to the polymerization In the kettle, the reaction temperature is 220°C, the reaction pressure is 80KPa, the reaction time is 2h, and then added, the reaction temperature is 235°C, the reaction pressure is 50KPa, and the reaction is 1.5h; then the temperature rises to 240°C, the reaction pressure is 100Pa, the reaction time is 1.5h, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com