Hobbing type reinforcing steel bar shredding cutter

A hobbing and cutting tool technology, which is applied in the field of hobbing and shredding steel bar shredding knives, can solve the problems of easy wear and tear of the knife teeth, achieve the effects of strong versatility, avoid excessive shearing, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

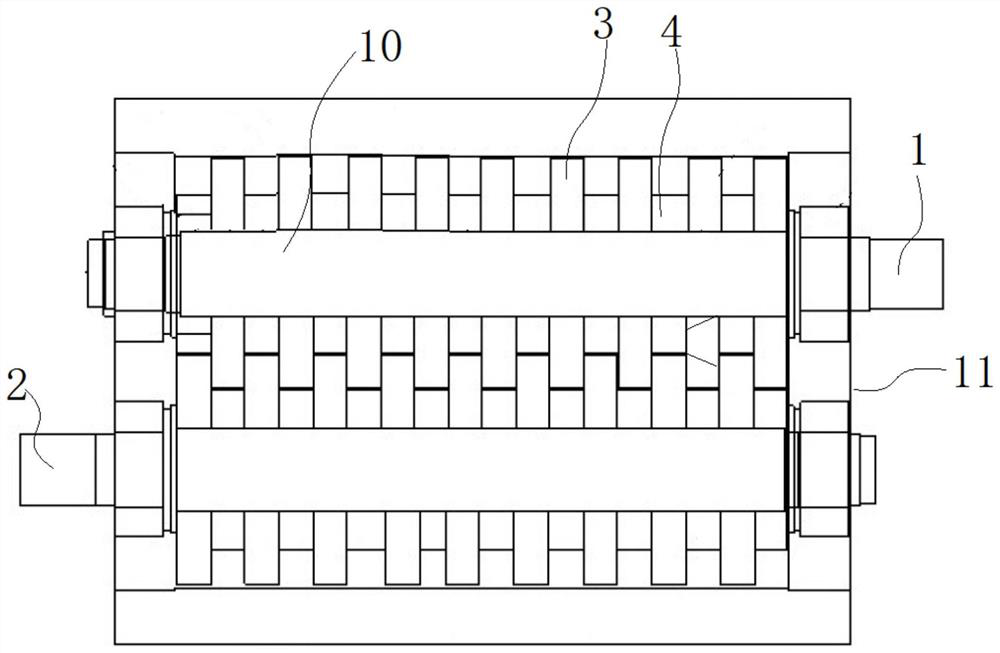

[0034] combine Figure 1-Figure 2 , the hobbing type steel bar shredding tool of the present embodiment comprises cutter shafts 10 arranged side by side, and circular blades 3 and spacers 4 fixed on the cutter shafts 10 alternately, and the outer peripheral surfaces of the blades 3 are alternately arranged There are cutter teeth 31 and cutter grooves 32, and the cross-sections of the cutter teeth 31 and the cutter grooves 32 in the horizontal direction along the axial direction of the cutter shaft 10 are both trapezoidal in shape, compared with radial or circumferential cutters with trapezoidal shapes. When shredding steel bars, the axially trapezoidal cutter teeth can achieve the effect of buffer shearing and shredding in specific applications, avoiding direct excessive shearing, thereby improving the service life of the cutter teeth. In specific applications, the cutter teeth 31 and the cutter grooves 32 and the blade 3 can be of an integrated structure or can be detachably ...

Embodiment 2

[0036] A kind of hobbing type steel bar shredding tool of the present embodiment, basic structure keeps consistent with embodiment 1, further, as Figures 3 to 5 As shown, the center of the blade 3 and the spacer 4 is a mounting hole 33 with a polygonal cross-section, matched with the same polygonal cutter shaft 10, the stability after installation is high, and relative sliding during shredding can be effectively avoided. In addition, the tooth directions of the trapezoidal cutter teeth 31 of the blades 3 on different cutter shafts 10 are in the same direction or facing away from each other, and different tooth directions can be selected according to materials of different specifications. The bottom angle of the trapezoidal shape of the cutter teeth 31 is 50°~70°, 60° is the most suitable. The number of cutter teeth 31 on each blade 3 is 8 to 10, and 9 is the most suitable. The cutter teeth 31 in this range take into account the shredding efficiency and service life. Specifical...

Embodiment 3

[0038] A kind of roll cutting type steel bar shredding tool of the present embodiment, the basic structure is consistent with embodiment 2, and further, comprises more than three groups of rolling cutting type steel bar shredding knives, such as Figure 6As shown, three groups of cutters are arranged vertically. Among the three groups of cutters, the tooth direction of the cutter teeth 31 is opposite to the upper group, the same direction is in the middle, and the back facing group is lower. The cutters with different tooth orientations are effectively arranged and divided, and the service life of the cutter teeth can be further improved under the premise of ensuring the shredding effect. In specific applications, since it is difficult to unify and classify the specifications of steel bars in large-scale dismantling factories, many specifications are often mixed together. If a set of knives is used, either the shreds will not be thorough, or the thicker steel bars will be rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com