Clutch device of wheel excavator

A technology for clutch devices and excavators, which is applied in the direction of non-mechanical drive clutches, clutches, control devices, etc., and can solve problems that affect work efficiency and operator fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

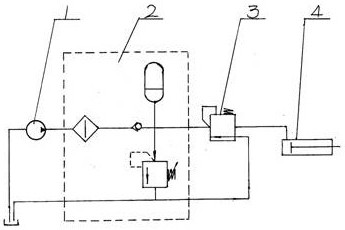

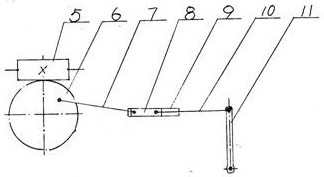

[0016] attached figure 1 And attached figure 2 A wheeled excavator clutch device according to the present invention includes a clutch and a clutch swing arm 11, the clutch is connected to one end of the clutch swing arm 11 through a fork lever, and the other end of the clutch swing arm 11 is connected to a separation device, and the separation device is Clutch separation oil cylinder 4, clutch separation oil cylinder 4 is also connected to one end of proportional valve 3 through a pipeline, the other end of proportional valve 3 is connected to one end of pilot oil source valve 2 through a pipeline, and the other end of pilot oil source valve 2 is connected to oil pump 1 through a pipeline, proportional The switch on the valve 3 is in contact with the pedal device arranged in the cab; the proportional valve 3 is a pedal proportional valve.

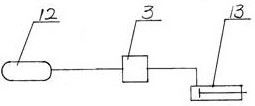

[0017] attached figure 2 A wheeled excavator clutch device shown can also include a clutch and a clutch swing arm 11, the clutch is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com