Rapid self-elevating offshore platform lifting system and control method thereof

A lifting system and offshore platform technology, applied in the field of fast self-elevating offshore platform lifting system and its control, can solve the problems of slow speed in the whole process, and achieve the effect of easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

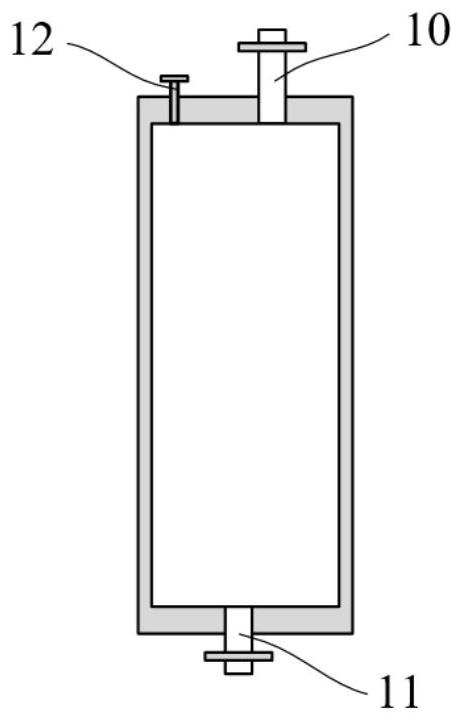

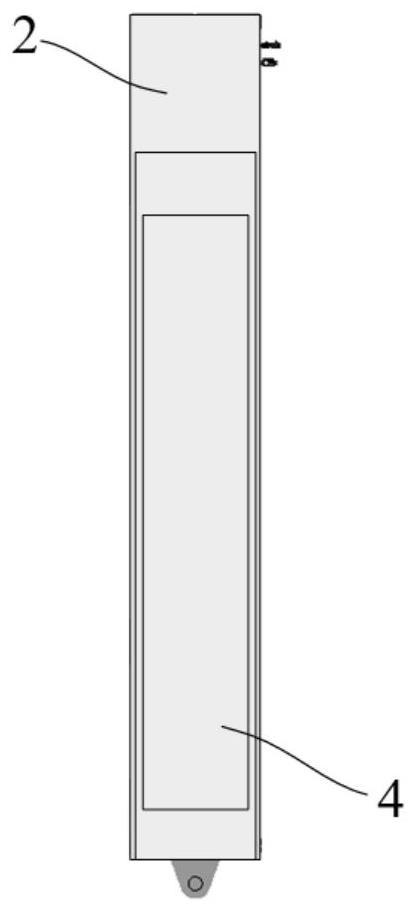

[0040] A specific embodiment of the present invention, such as Figure 1-Figure 4 As shown, a fast self-elevating offshore platform lifting system (hereinafter referred to as the lifting system) is disclosed, which includes pile legs 8 and a lifting mechanism. The interior is filled with phase-change gas, and the air pressure of the phase-change gas quickly expands and builds pressure to drive and push the pile insertion push rod 4 to drive the pile leg 8 into the mud for ballasting to realize the rapid lifting of the platform 13.

[0041] Compared with the prior art, the lifting system provided by this embodiment uses the air pressure of the phase-change gas to quickly expand and build up pressure to drive the pile insertion push rod to drive the pile legs into the mud and ballast to realize the rapid lifting of the platform. Due to the rapid build-up of the phase-change gas The process of pressing, pushing, ballasting and lifting is generally completed within a few minutes t...

Embodiment 2

[0054] Another specific embodiment of the present invention, such as Figure 1-Figure 4 As shown, a control method of a fast self-elevating offshore platform lifting system is disclosed, and the steps include:

[0055] Step S1: The pile legs 8 are lowered, and after they are put in place, the pile legs 8 and the platform 13 are locked, and the driving frame 5 and the pile legs 8 are locked.

[0056] After the platform 13 is towed to the designated operating position, the legs 8 drop to the seabed under the action of the lifting motor 7, during which the transmission frame 5 and the legs 8 are in an unlocked state.

[0057] It should be noted that during the hauling process of the platform 13, the legs 8 are lowered to the point where they do not touch the sea water, so as to lower the center of gravity of the entire platform 13 system and avoid the shaking of the legs 8 caused by the external force of sea water and waves during the hauling process. During the lowering process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com