Preparation method of knitted fabric with differential water conduction function

A technology of knitted fabrics and water conduction, applied in the field of textile fabrics, can solve the problems of narrow range of suitable fabrics, affecting softness and comfort, poor washability, etc., to achieve uniform and stable unidirectional moisture transfer ability, dry and comfortable and non-sticky to wear body, to meet the effect of wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

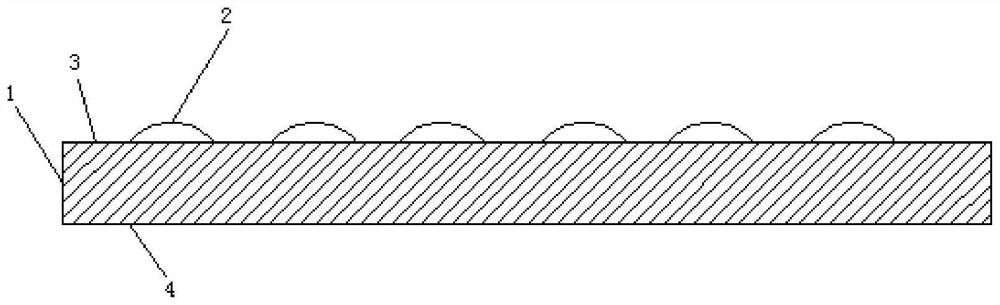

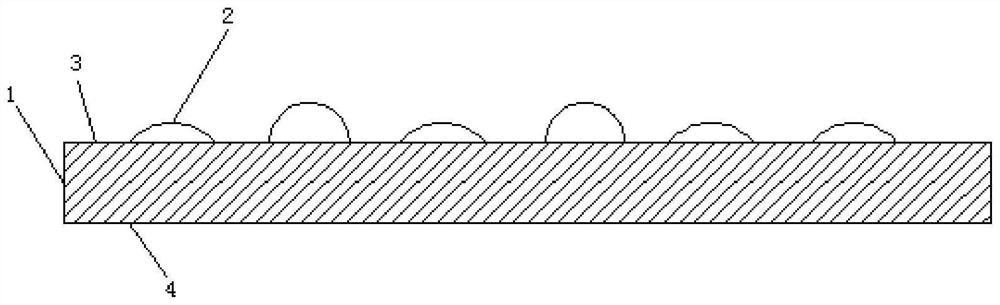

[0032] If attached Figure 1-3 As shown, the present invention reveals a method for preparing a knitted fabric having a differentiated water conduction function, comprising the following steps:

[0033] The selection of composite yarn as a raw material, in the present embodiment one, the composite yarn is composed of a single material of the first fiber, the second fiber, the first fiber, the second fiber of the curl shrinkage rate is different, wherein the first fiber of the curl shrinkage rate is set to higher than the curl shrinkage of the second fiber.

[0034] The fabric body with a garment face and a skin veneer surface is woven by a composite yarn consisting of a first and second fibers1.

[0035]In the weaving process, the fibers with a high curl shrinkage rate in the composite yarn will form a raised part with a height of 0.01mm-0.5mm, the raised part is located on the skin surface, the bulge part is formed as a skin-to-skin wet part with a high probability of contact wit...

Embodiment approach 2

[0039] On the basis of embodiment one, for the specific composition of the composite yarn, there may be a number of different ways. The fibers of each single material with different curl shrinkage rates selected are mixed to form a composite yarn, and the fibers of each single material are interwound to form a composite yarn, or at least one of the fibers is used as the core, and the other fibers are wound on the core to form a core composite yarn.

[0040] The following example is that composite yarn is composed of two fibers of a single material.

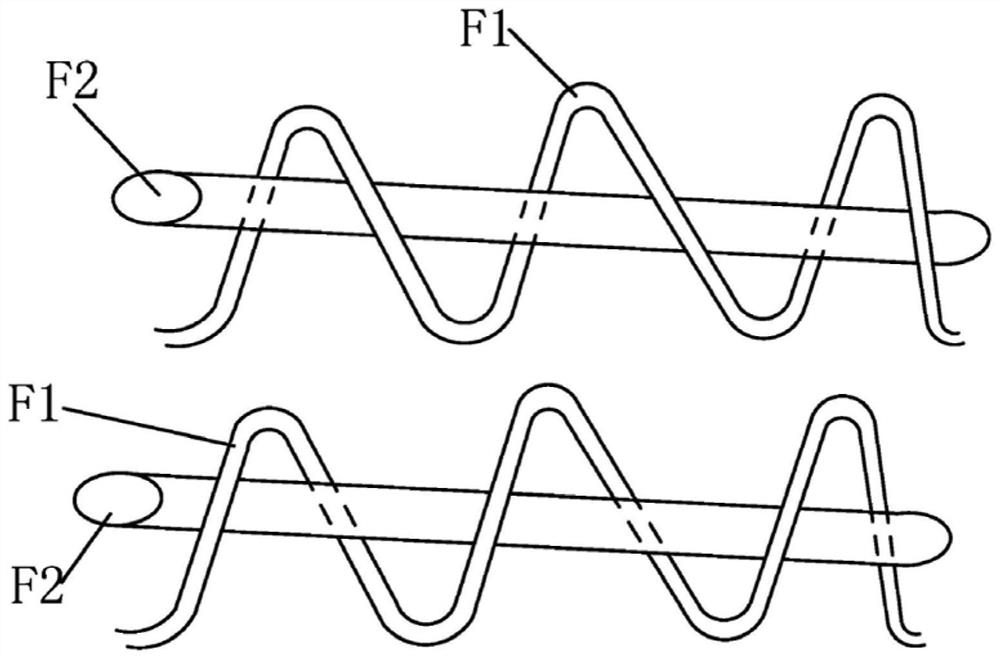

[0041] If attached Figure 2As shown, the composite yarn is a composite yarn with a core structure composed of a first fiber and a second fiber uniformly wound on the surface of the first fiber.

[0042] Or the second form, the composite yarn is formed by the first fiber and the second fiber intertwined with each other.

[0043] Or a third form, the yarn comprises both the first fiber and the second fiber intertwined to form a portion...

Embodiment approach 3

[0046] On the basis of embodiment one, the garment surface is involved in the contact angle between the composite yarn and liquid water evaporation θ 1 ≤65 0 。 The contact angle θ between the composite yarn of the skin surface in contact with the liquid water 2 ≤70 0 , and θ 2 / θ 1 ≥1。 The contact angle of the first and second fibers can be set to ensure adequate moisture conductivity when conducting moisture.

[0047] Further, the fineness of the fibers of each single material in the composite yarn is different, and the fineness of the fiber with high curl shrinkage is greater than that of the fiber with low curl shrinkage, the number of single fiber roots of the fiber with high curl shrinkage is less than the number of single fiber roots of the fiber with low curl shrinkage. Thus, the fineness of the first fiber with high curl shrinkage is larger, the number of single fibers is smaller, and the fineness of the second fiber with low curl shrinkage is smaller, and the number of si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com