Preparation method of filtrate reducer and filtrate reducer

A technology of fluid loss control agent and initiator, which is applied in the field of drilling, can solve the problems of poor environmental protection of fluid loss control agent, and achieve good fluid loss control effect, low addition amount, and good fluid loss control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

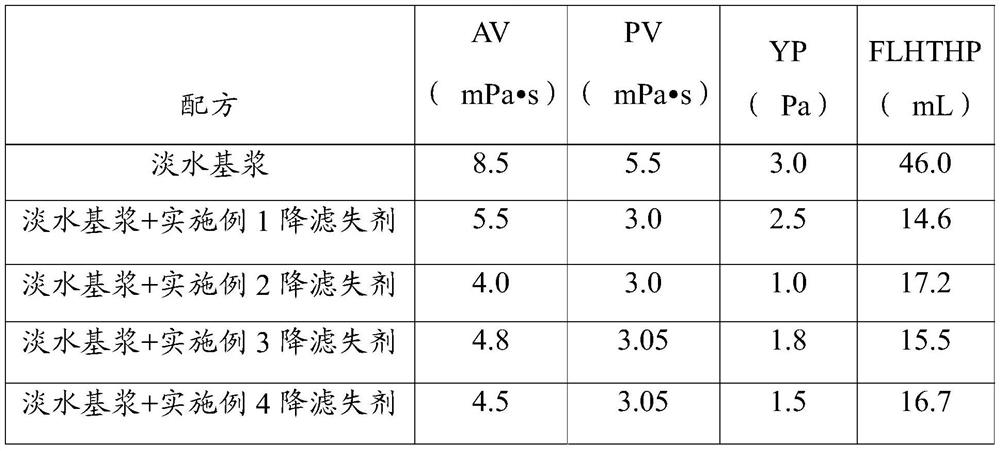

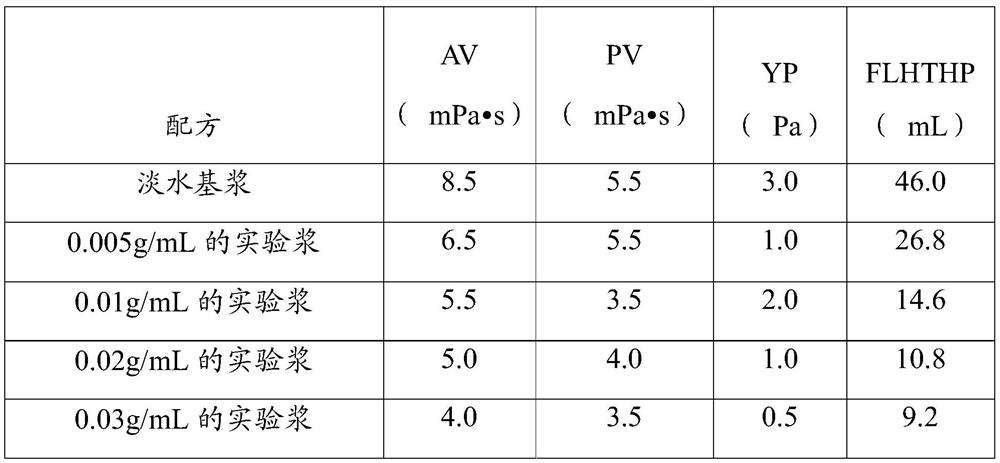

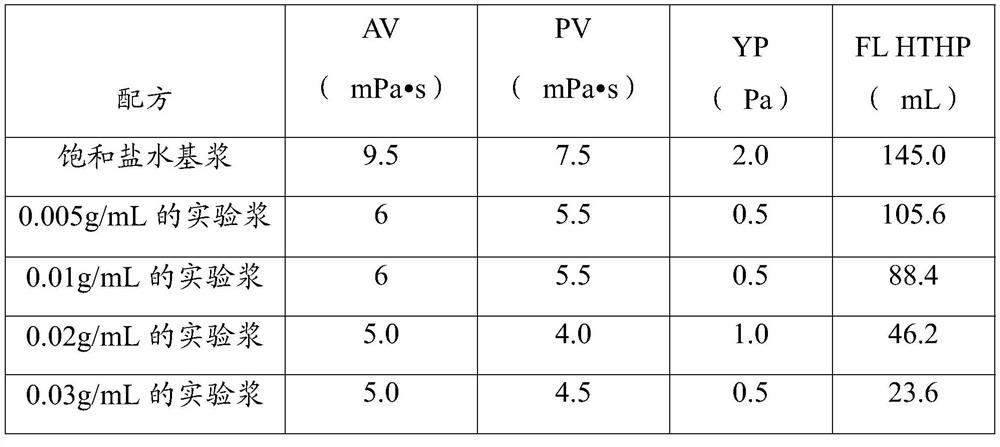

Examples

preparation example Construction

[0029] On the one hand, the embodiment of the present invention provides a preparation method of a fluid loss control agent, the preparation method of the fluid loss control agent comprises: providing a preparation raw material, and using the preparation raw material to carry out a polymerization reaction to obtain a fluid loss control agent.

[0030] Wherein, the preparation raw material includes the following components by weight: 5-20 parts of the first anionic monomer, 15-22 parts of the second anionic monomer, 18-30 parts of the hydrophobic monomer, 4-15 parts of the cationic monomer, 0.6-0.8 parts of initiator, 40-60 parts of water, 12-20 parts of pH regulator;

[0031] Wherein, the first anionic monomer is maleic anhydride and / or acrylic acid;

[0032] The second anionic monomer is 2-acrylamide-2-methylpropanesulfonic acid and / or sodium allylsulfonate.

[0033] Exemplarily, the parts by weight of the first anionic monomer include but are not limited to: 10 parts, 15 pa...

Embodiment 1

[0067] This embodiment 1 provides a fluid loss control agent, which is prepared by the following preparation method:

[0068] Step 101: Provide preparation raw materials, which include the following components by weight: 10 parts of the first anionic monomer, 21 parts of the second anionic monomer, 19 parts of the hydrophobic monomer, 8 parts of the cationic monomer, and 0.6 parts of the initiator 45 parts, 45 parts of water, 20 parts of pH regulator.

[0069] Wherein, the first anionic monomer is maleic anhydride; the second anionic monomer is 2-acrylamide-2-methylpropanesulfonic acid; the hydrophobic monomer is selected from acrylamide, N,N-dimethylacrylic acid Amide; cationic monomer is selected from methacryloyloxyethyltrimethylammonium chloride; initiator is ammonium persulfate and sodium bisulfite with a mass ratio of 1:1; pH regulator is selected from Ca(OH) 2 .

[0070] Step 102: Mix the first anionic monomer, the second anionic monomer, the hydrophobic monomer, the ...

Embodiment 2

[0076] This embodiment 2 provides a fluid loss control agent, which is prepared by the following preparation method:

[0077] Step 201: Provide preparation raw materials, which include the following components by weight: 18 parts of the first anionic monomer, 22 parts of the second anionic monomer, 25 parts of the hydrophobic monomer, 12 parts of the cationic monomer, and 0.8 parts of the initiator 50 parts, 50 parts of water, 18 parts of pH regulator.

[0078] Wherein, the first anionic monomer is acrylic acid; the second anionic monomer is sodium allyl sulfonate; the hydrophobic monomer is selected from acrylamide; the cationic monomer is selected from methacryloxyethyltrimethylammonium chloride ; Initiator mass ratio is 1:1 potassium persulfate and sodium bisulfite; PH regulator is selected from KOH.

[0079] Step 202: Mix the first anionic monomer, the second anionic monomer, the hydrophobic monomer, the cationic monomer, and water in a reaction vessel evenly.

[0080] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com