Temporary plugging agent for drilling fluid

A technology of temporary plugging agent and drilling fluid, which is applied in the fields of oil-soluble resin temporary plugging agent and drilling fluid temporary plugging agent. , On-site use is convenient, the effect of restoring permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

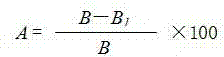

Method used

Image

Examples

Embodiment 1

[0075] A temporary plugging agent for drilling fluid is a polymer prepared from the following raw materials in parts by weight:

[0076] Hexadecene 60% Sodium Persulfate 0.5%

[0077] Phenol 20%

[0078] 4% formaldehyde solution 18%

[0079] Cetyltrimethylammonium Chloride 2%.

[0080] The preparation method of temporary plugging agent for described drilling fluid comprises the steps:

[0081] (1) Add phenol and catalyst sodium persulfate to hexadecene for alkylation reaction at a reaction temperature of 80±5°C and a pressure of 2±0.5MPa;

[0082] (2) Add 4% formaldehyde solution to the reactant obtained in step (1) for grafting aldehyde group reaction to generate resin, the reaction temperature is 40±5°C, and the pressure is 2±0.5MPa;

[0083] (3) Add cationic surfactant to the resin obtained in step (2) to fully emulsify the resin, the reaction temperature is 40±5°C, and the pressure is 2±0.5MPa;

[0084] (4) Dry the polymer obtained in step (3) at 100±5°C, and pu...

Embodiment 2

[0086] A temporary plugging agent for drilling fluid is a polymer prepared from the following raw materials in parts by weight:

[0087] Hexadecene 65%

[0088] Sodium persulfate 1%

[0089] Phenol 20%

[0090] 4% formaldehyde solution 12%

[0091] Cetyltrimethylammonium Chloride 2%.

[0092] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0094] A temporary plugging agent for drilling fluid is a polymer prepared from the following raw materials in parts by weight:

[0095] Hexadecene 70%

[0096] Sodium persulfate 1%

[0097] Phenol 15%

[0098] 4% formaldehyde solution 12%

[0099] Cetyltrimethylammonium Chloride 2%.

[0100] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com